Method for filling mine goaf and sealing and storing solidified CO2 by using foam geopolymer

A technology of geopolymers and gobs, applied in chemical instruments and methods, carbon compounds, applications, etc., can solve the problems of escaping and releasing into the atmosphere, storage and other problems, and achieve the effect of large storage capacity and high curing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

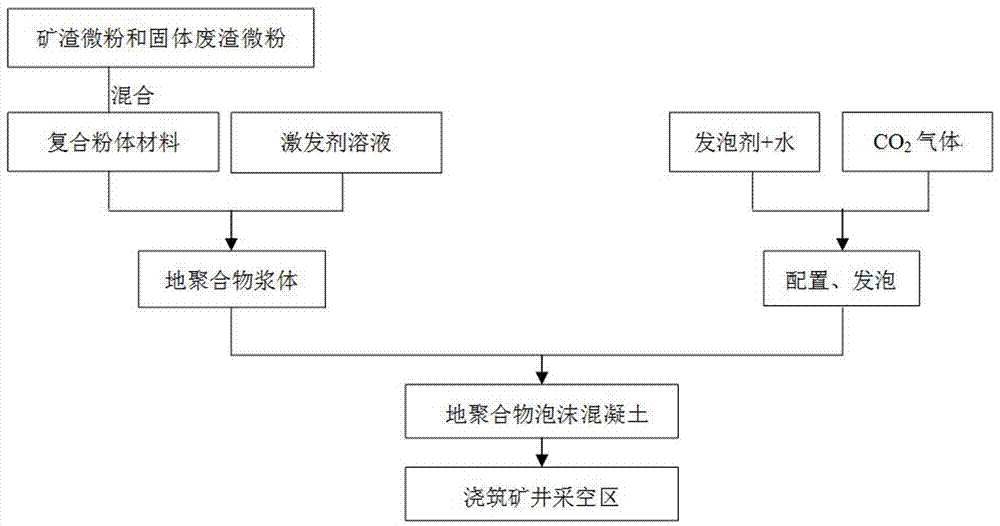

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the embodiments.

[0032] 1. Select the gob area of a mine in Xuzhou with steeply inclined thin coal seams;

[0033] 2. Storage of CO 2 Preparation of gas-foamed geopolymers:

[0034] (1) Preparation of composite powder materials: The solid powder materials are slag micropowder produced by Xuzhou Chengyi Cement Plant and secondary fly ash of Xuzhou Maocun Thermal Power Plant. The slag fine powder and fly ash are transported by bulk tank trucks, respectively unloaded into the vertical silo by compressed air, transported to the metering hopper by the screw conveyor at the bottom of the silo, and added to the mixer to obtain a composite powder material. The mass percentage of each component of the composite powder material: 50% of slag fine powder, 50% of fly ash.

[0035] (2) Alkali excitation solution preparation: Dilute the liquid water glass with a modulus of 1.0 and a solid conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com