Preparation method of silane modified attapulgite clay and application thereof in removing pesticide residues from Chinese herbal medicines

A silane modification, Chinese herbal medicine technology, applied in chemical instruments and methods, other chemical processes, ion exchange, etc., can solve the problems of complex methods and difficult to operate, and achieve the effects of abundant storage, easy access to prices, and no potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

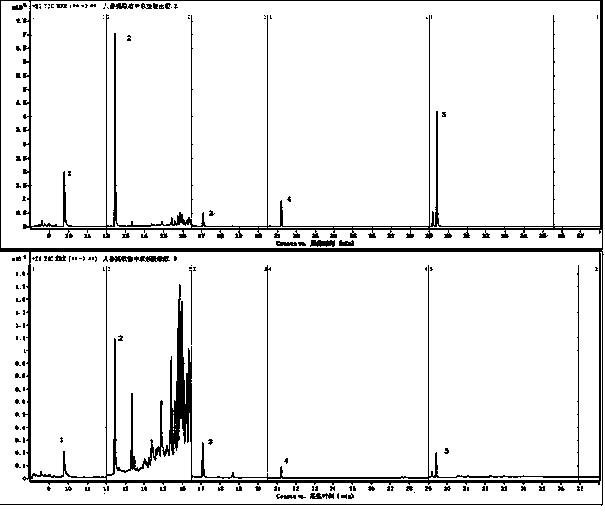

Examples

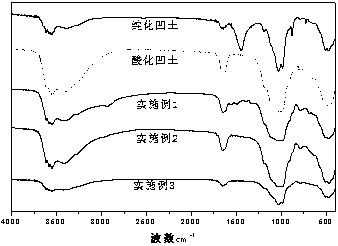

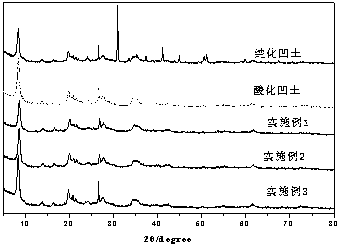

Embodiment 1

[0036] Put the attapulgite and water in a beaker at a ratio of 1:20, stir at room temperature for 2 days, and let it stand for 2 days. After precipitation, take the middle layer and put it in another beaker. After replenishing water to the original volume, repeat the above steps 2-3 Second-rate. Finally, take the middle layer and place it in an oven at 105°C for drying, weighing, and grinding. Mix purified attapulgite with 1 mol·L -1 Acidify with hydrochloric acid at a ratio of 1:20, stir at room temperature for 2 days, let stand for 2 days, wash the clay solid in the lower layer with distilled water several times, filter with suction, dry, grind, pass through a 150-mesh sieve, and acidify the attapulgite. Take 10g of acidified attapulgite and 100mL of toluene in a 250mL three-necked flask, add 0.7g of KH-792, 1mL of triethylamine, stir magnetically, and heat to reflux for 24 hours. After the reaction, the attapulgite is washed repeatedly with ethanol until the coupling agent...

Embodiment 2

[0039] Put the attapulgite and water in a beaker at a ratio of 1:40, stir at room temperature for 2 days, and let it stand for 2 days. After precipitation, take the middle layer and put it in another beaker. After replenishing water to the original volume, repeat the above steps 2-3 Second-rate. Finally, take the middle layer and place it in an oven at 105°C for drying, weighing, and grinding. Mix purified attapulgite with 1 mol·L -1Acidify with hydrochloric acid at a ratio of 1:25, stir at room temperature for 2 days, let stand for 2 days, wash the lower clay solid with distilled water several times, filter with suction, dry, grind, pass through a 150-mesh sieve, and acidify the attapulgite. Take 10g of acidified attapulgite and 80mL of methanol-water into a 250mL three-necked flask, add 0.5g of KH-550 and 0.8mL of triethylamine, stir magnetically, and heat to reflux for 24 hours. After the reaction, attapulgite is washed repeatedly with ethanol until even The joint agent w...

Embodiment 3

[0042] Put the attapulgite and water in a beaker at a ratio of 1:50, stir at room temperature for 2 days, and let it stand for 2 days. After precipitation, take the middle layer and put it in another beaker. After replenishing water to the original volume, repeat the above steps 2-3 Second-rate. Finally, take the middle layer and place it in an oven at 105°C for drying, weighing, and grinding. Mix purified attapulgite with 1 mol·L -1 Acidify with hydrochloric acid at a ratio of 1:30, stir at room temperature for 2 days, let stand for 2 days, wash the clay solid in the lower layer with distilled water several times, filter with suction, dry, grind, pass through a 150-mesh sieve, and acidify the attapulgite. Take 10g of acidified attapulgite and 120mL of ethanol-water into a 250mL three-necked flask, add 1g of KH-1161 and 1.2mL of triethylamine, stir magnetically, and heat to reflux for 24 hours. After the reaction, the attapulgite is washed repeatedly with ethanol until coupli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com