A method for in-situ deep in-situ supercritical storage of flue gas

A flue gas and supercritical technology, which is applied in earth drilling, climate sustainability, and other gas emission reduction technologies, can solve problems such as high costs, slow process steps, and huge equipment investment costs, and achieve storage capacity Large, diffuse, rich storage capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

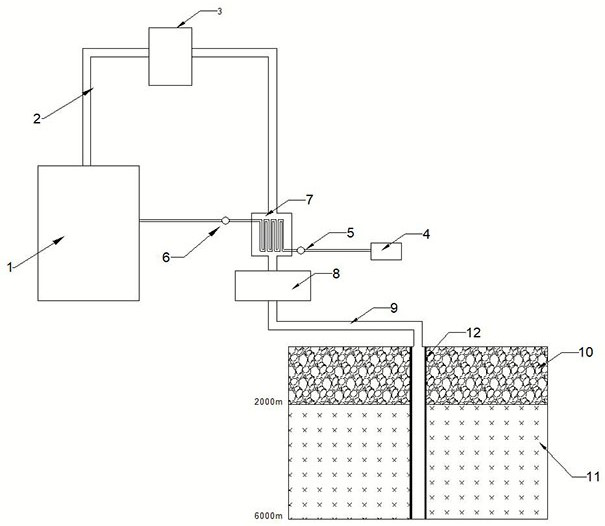

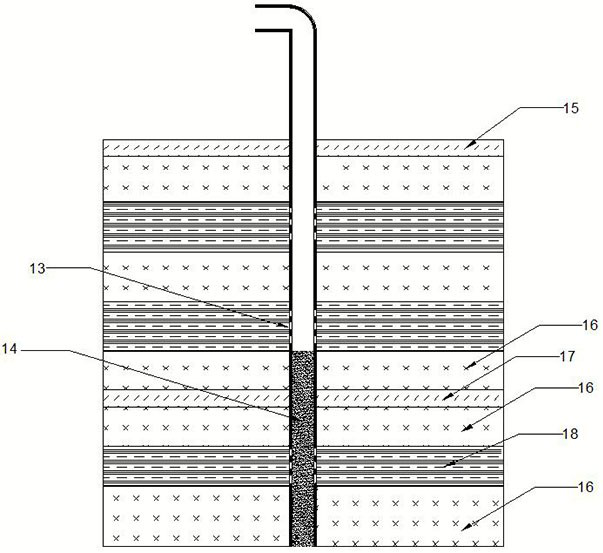

[0041] A method for in-situ and deep supercritical storage of power plant flue gas, such as figure 1 , 2 , 3 and 6, the specific steps are as follows:

[0042] 1) Under the condition that the normal power generation of the power plant and the safety and stability of the power facilities are not affected, deep drilling is carried out in a certain range of open space in the power plant area 1. The drilling depth exceeds 2000m, and the target well depth reaches 5000m-7000m. Casing 12 is installed in the hole and cemented.

[0043] 2) Sampling the cores of different formations over 2000m in the drilling, and experimentally measure the porosity, permeability, water content, gas adsorption / desorption rate and mechanical strength parameters of rocks in different formations, and combine the relevant geological and hydrological conditions with the formation. Conditions (thickness, dip, water content, and fault characteristics), through comprehensive evaluation, analysis and screening...

Embodiment 2

[0050] A method for in-situ and deep supercritical storage of power plant flue gas, such as figure 1 , 2 , 4 and 6, the specific steps are as follows:

[0051] 1) Under the condition that the normal power generation of the power plant and the safety and stability of the power facilities are not affected, deep drilling is carried out in a certain range of open space in the power plant area 1. The drilling depth exceeds 2000m, and the target well depth reaches 5000m-7000m. Casing 12 is installed in the hole and cemented.

[0052] 2) Sampling the cores of different formations over 2000m in the drilling, and experimentally measure the porosity, permeability, water content, gas adsorption / desorption rate and mechanical strength parameters of rocks in different formations, and combine the relevant geological and hydrological conditions with the formation. Conditions (thickness, dip, water content, and fault characteristics), through comprehensive evaluation, analysis and screening...

Embodiment 3

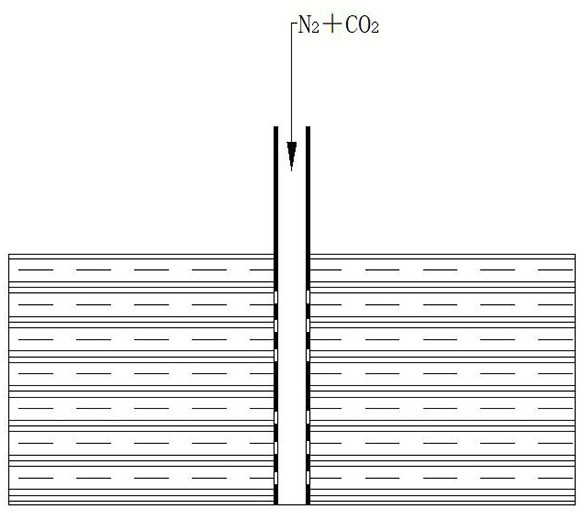

[0060] A method for in-situ and deep supercritical storage of power plant flue gas, such as figure 1 , 2 , 5 and 6, the specific steps are as follows:

[0061] 1) Under the condition that the normal power generation of the power plant and the safety and stability of the power facilities are not affected, deep drilling is carried out in a certain range of open space in the power plant area 1. The drilling depth exceeds 2000m, and the target well depth reaches 5000m-7000m. Casing 12 is installed in the hole and cemented.

[0062] 2) Sampling the cores of different formations over 2000m in the drilling, and experimentally measure the porosity, permeability, water content, gas adsorption / desorption rate and mechanical strength parameters of rocks in different formations, and combine the relevant geological and hydrological conditions with the formation. Conditions (thickness, dip, water content, and fault characteristics), through comprehensive evaluation, analysis and screening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com