A combined truncate

A truncator and multi-fracture technology, which is applied to overvoltage arresters, electrical components, spark gaps, etc. using spark gaps, can solve the problems of large discharge counters, less arc extinguishing effect, and need for manual recording to achieve protection. Safety, improve arc extinguishing performance, and facilitate the effect of entering the trigger position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

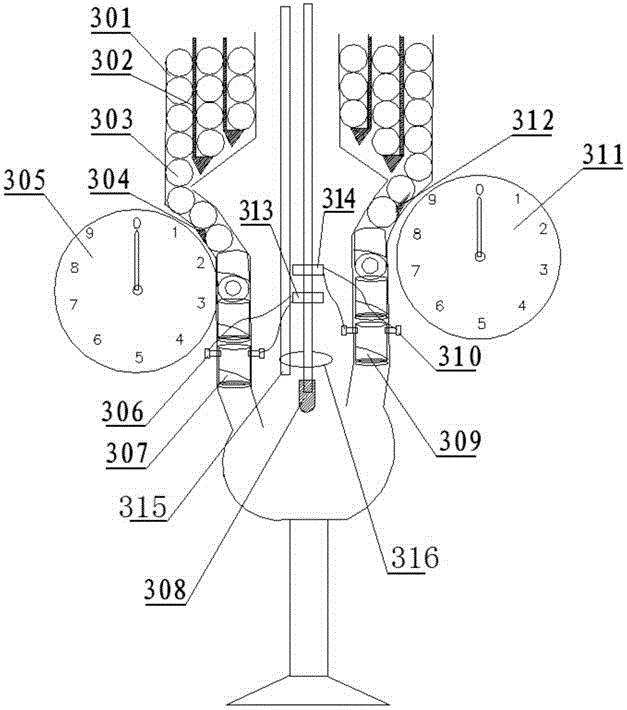

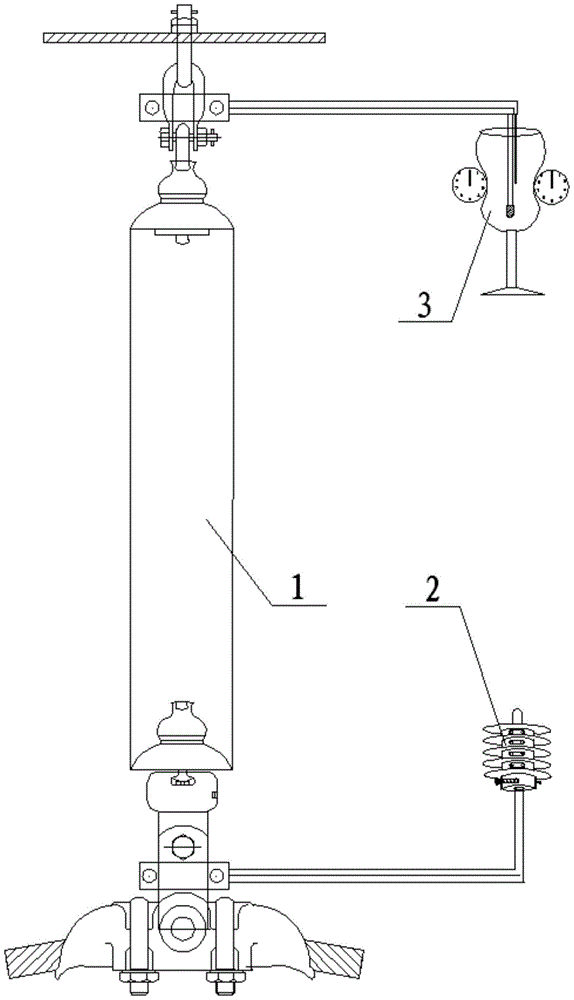

[0046] Such as Figure 1-5 As shown, a combined circuit breaker includes a multi-fracture arc extinguishing device 2 and a horizontal arc extinguishing device 3 fixedly installed at both ends of the insulator 1 through connecting fittings I and connecting fittings II respectively; wherein,

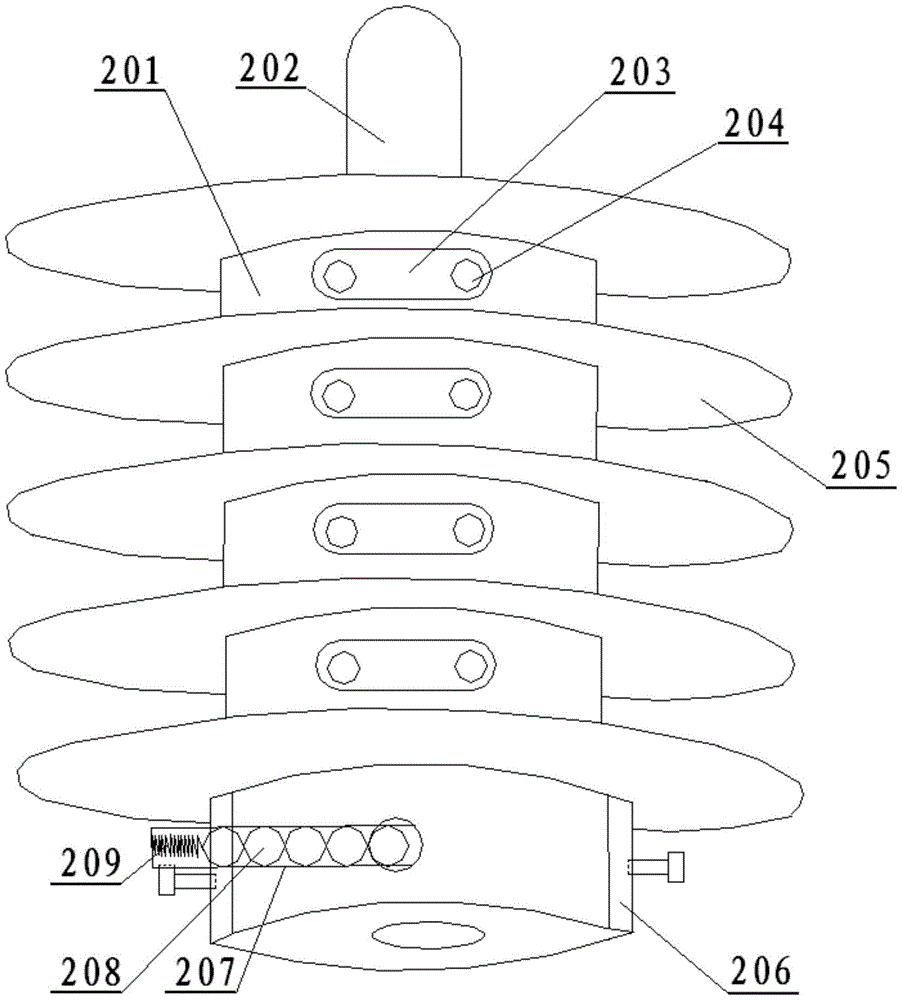

[0047] The multi-fracture arc extinguishing device 2 includes a device main body 201 and an arc starting electrode I 202; the arc starting electrode I 202 is fixedly installed at one end of the device main body 201, and points to the horizontal arc extinguishing device 3, and the other end of the device main body 201 It is fixedly installed at one end of the insulator 1 through the connecting fitting I; the device main body 201 is provided with an arc extinguishing path 204 composed of several sections of arc extinguishing channels 210 and arranged in a Z-shaped cycle; two adjacent arc extinguishing channels 210 is provided with a copper block 203, and each section of the arc extinguishing...

Embodiment 2

[0056] A combined circuit breaker, including a multi-fracture arc extinguishing device 2 and a horizontal arc extinguishing device 3 fixedly installed at both ends of an insulator 1 through connecting fittings I and connecting fittings II; wherein,

[0057] The multi-fracture arc extinguishing device 2 includes a device main body 201 and an arc starting electrode I 202; the arc starting electrode I 202 is fixedly installed at one end of the device main body 201, and points to the horizontal arc extinguishing device 3, and the other end of the device main body 201 It is fixedly installed at one end of the insulator 1 through the connecting fitting I; the device main body 201 is provided with an arc extinguishing path 204 composed of several sections of arc extinguishing channels 210 and arranged in a Z-shaped cycle; two adjacent arc extinguishing channels 210 is provided with a copper block 203, and each section of the arc extinguishing channel 210 is placed with two arc extingu...

Embodiment 3

[0065] A combined circuit breaker, including a multi-fracture arc extinguishing device 2 and a horizontal arc extinguishing device 3 fixedly installed at both ends of an insulator 1 through connecting fittings I and connecting fittings II; wherein,

[0066] The multi-fracture arc extinguishing device 2 includes a device main body 201 and an arc starting electrode I 202; the arc starting electrode I 202 is fixedly installed at one end of the device main body 201, and points to the horizontal arc extinguishing device 3, and the other end of the device main body 201 It is fixedly installed at one end of the insulator 1 through the connecting fitting I; the device main body 201 is provided with an arc extinguishing path 204 composed of several sections of arc extinguishing channels 210 and arranged in a Z-shaped cycle; two adjacent arc extinguishing channels 210 is provided with a copper block 203, and each section of the arc extinguishing channel 210 is placed with two arc extingu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com