Gas lift reverse circulation hole cleaning test simulation device

A technology of gas lift reverse circulation and simulation device, which is applied in the field of gas lift reverse circulation hole cleaning test simulation device, can solve problems such as being unfavorable to the promotion of gas lift reverse circulation slag cleaning, and achieve the effect of construction science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

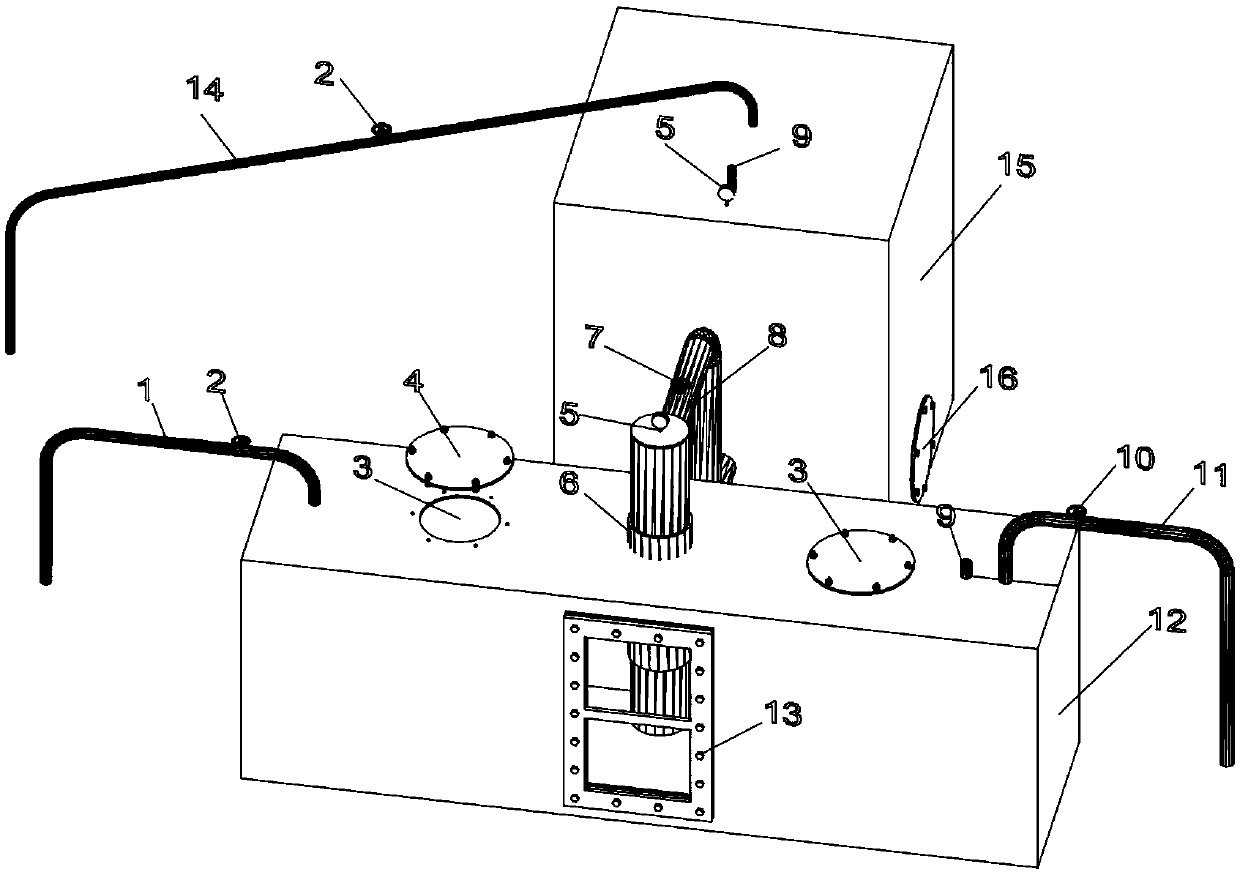

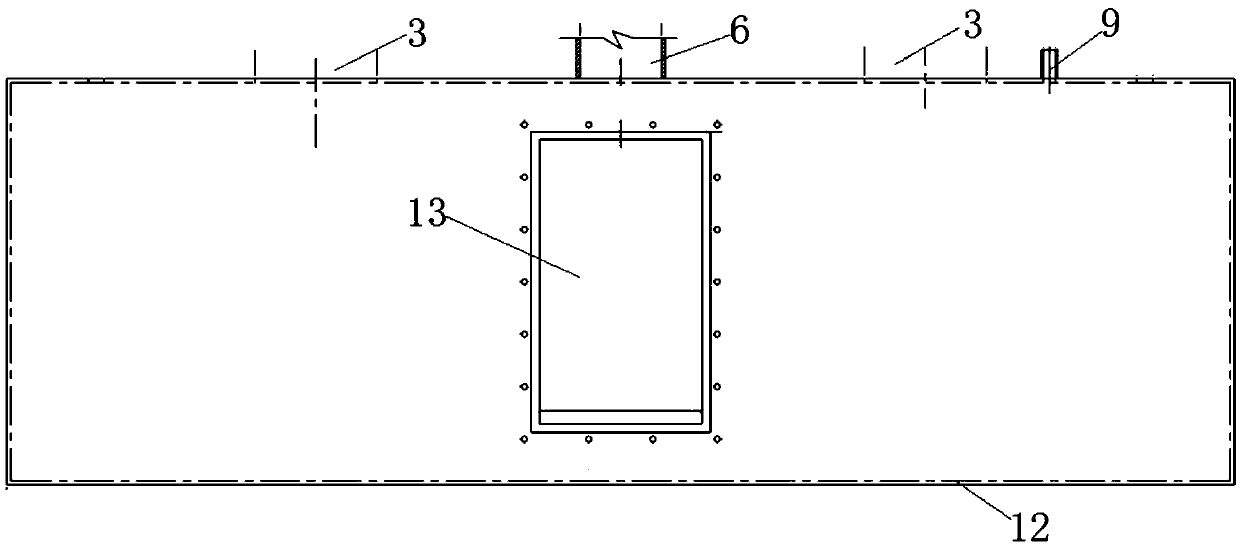

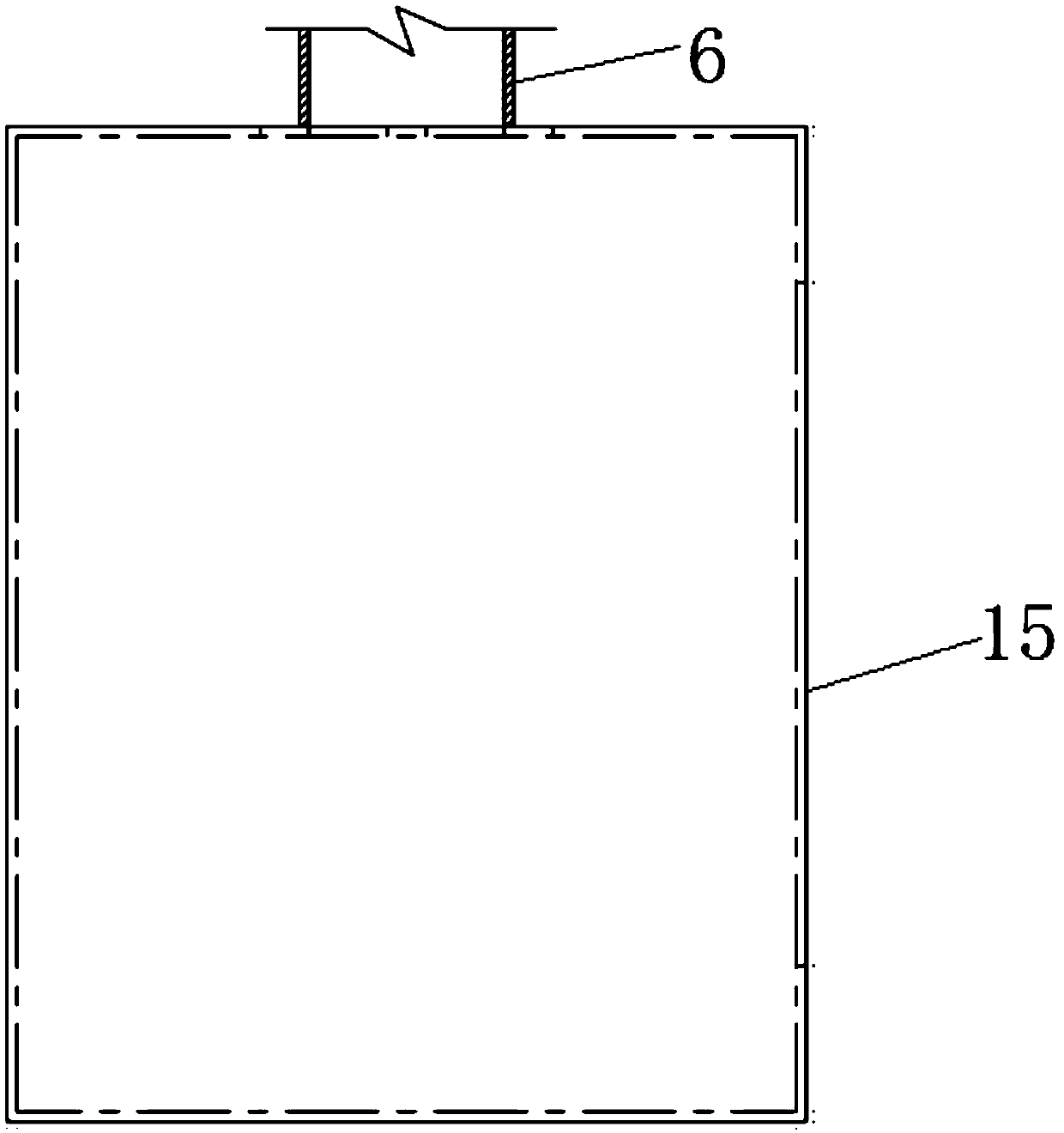

[0075] figure 1 A schematic diagram of a gas lift reverse circulation hole cleaning test simulation device according to an embodiment of the present invention is shown. figure 2 A front view of a mud mixing box according to one embodiment of the present invention is shown. image 3 A side view of a mud mixing box according to one embodiment of the invention is shown. Figure 4 A top view of mud mixing according to one embodiment of the invention is shown. Figure 5 A front view of a waste residue collection box according to an embodiment of the present invention is shown. Figure 6 A side view of a waste collection box according to one embodiment of the present invention is shown. Figure 7 It shows a top view of a waste residue collection box according to an embodiment of the present invention. Figure 8 A perspective view of a waste residue collection box according to an embodiment of the present invention is shown. Figure 9 It shows the internal structure diagram of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com