One-time slip-form construction method for multi-layer platform chimney with square variable cross-section under high wind pressure

A multi-layer platform and construction method technology, applied in the direction of formwork/formwork/work frame, tower, building type, etc., can solve the problems of wasted construction period, resources, low construction efficiency, etc., to save construction period, construction science, increase the overall Effects of Sex and Stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be further described below with reference to the drawings and examples.

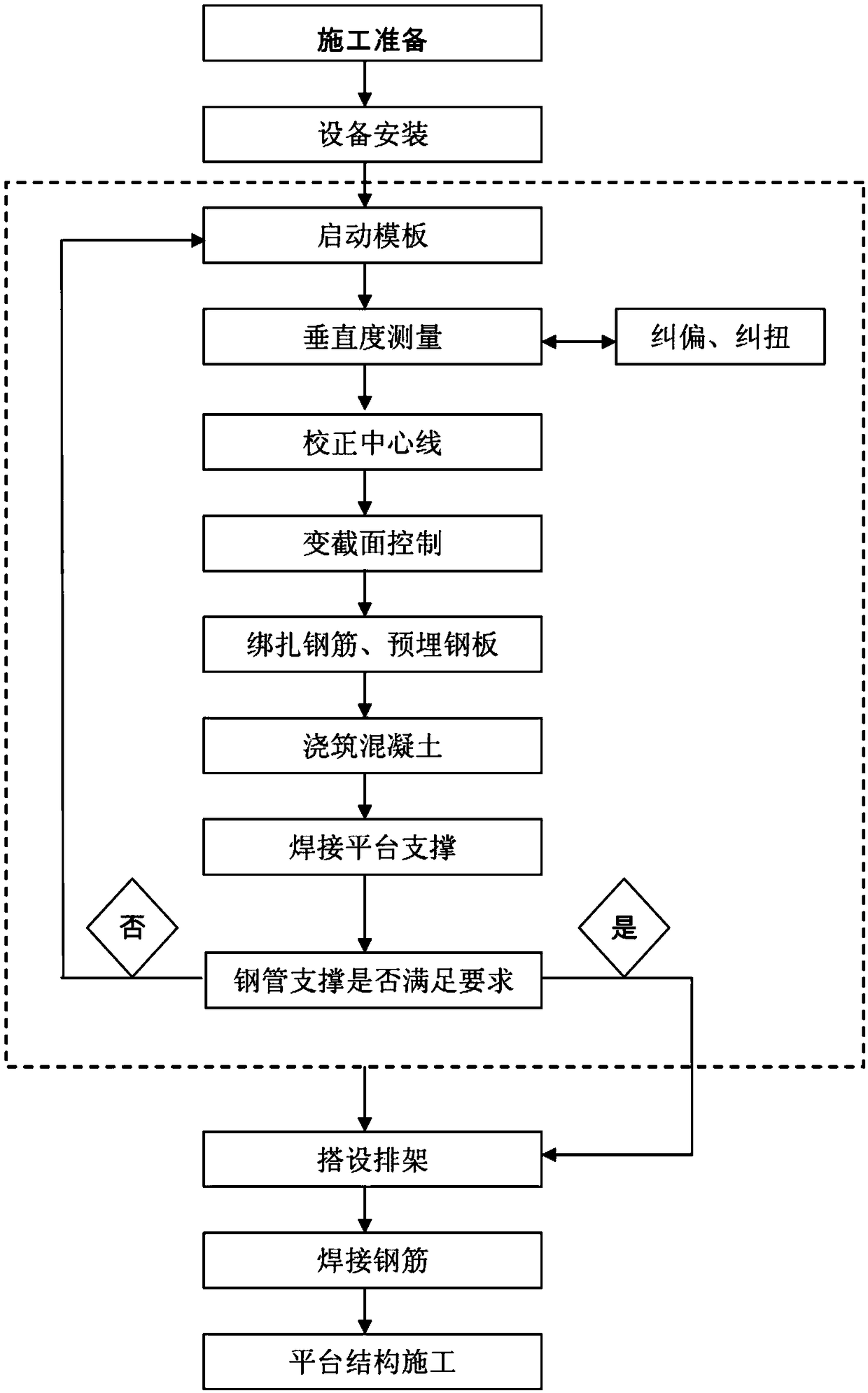

[0032] The one-time slip form construction method of a square variable section multi-layer platform chimney under high wind pressure according to the present invention is specifically implemented as follows:

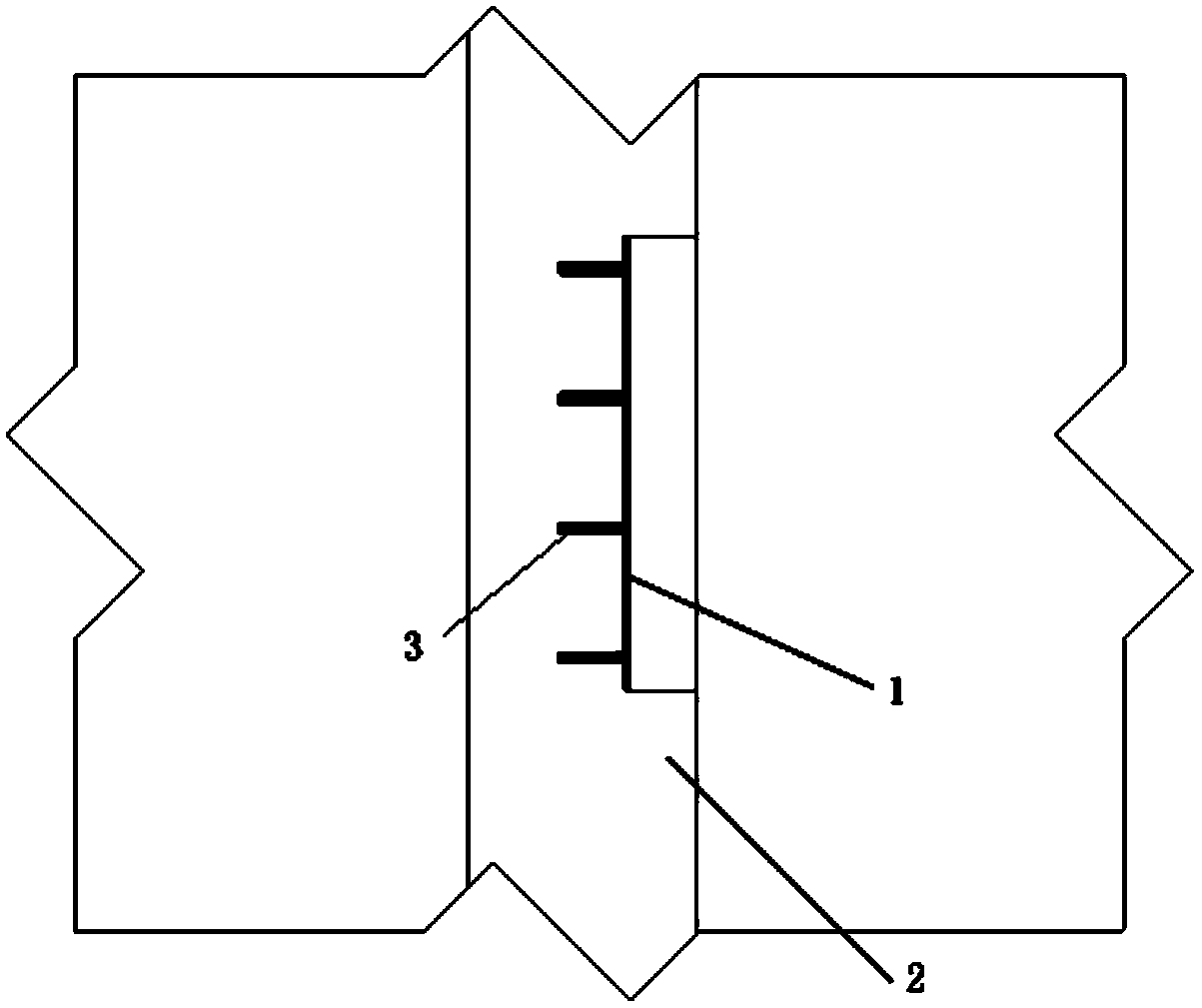

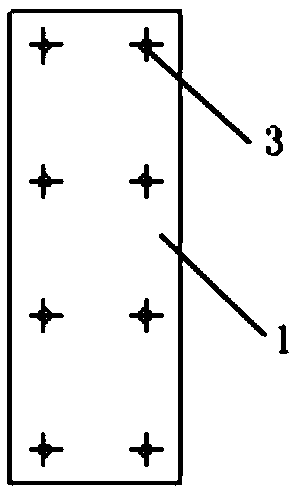

[0033] 1. Construction preparation: According to the design data, consult the relevant specifications, use Abaqus finite element analysis software to carry out the displacement curve and stress change of the chimney body along the height change under the action of wind pressure. According to the analysis results, it is determined that the φ200×3.5 steel pipe is welded into an internal octagonal overall support form, and the stress-strain curve of the octagonal platform steel pipe support is analyzed. At the same time, 12 wind pressure sensors are evenly arranged around the outside of the sliding mold device, 3 on each side, to monitor the wind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com