Split type impeller

A split-type impeller technology, which is applied to non-variable pumps, liquid fuel engines, and parts of pumping devices for elastic fluids. Problems such as the inability to change the blade angle can achieve the effect of simplifying the design and manufacturing process, saving the cost of use, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

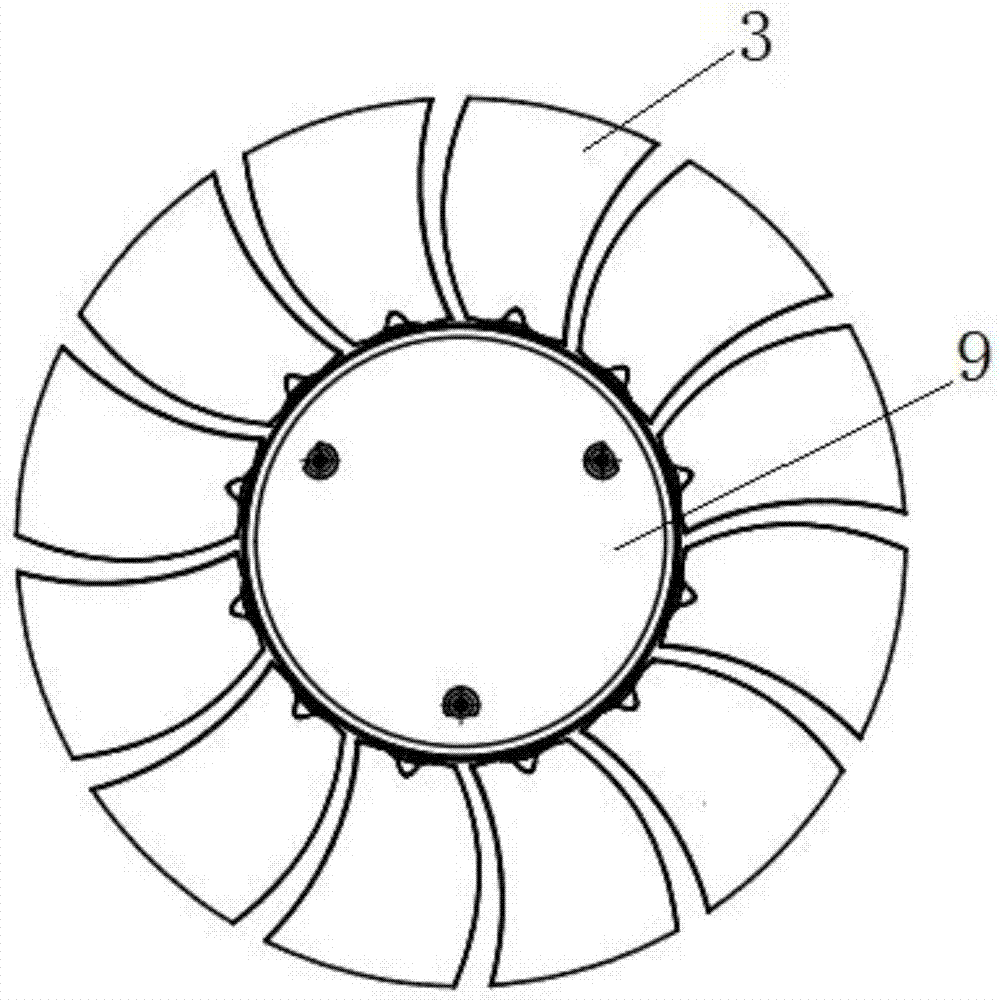

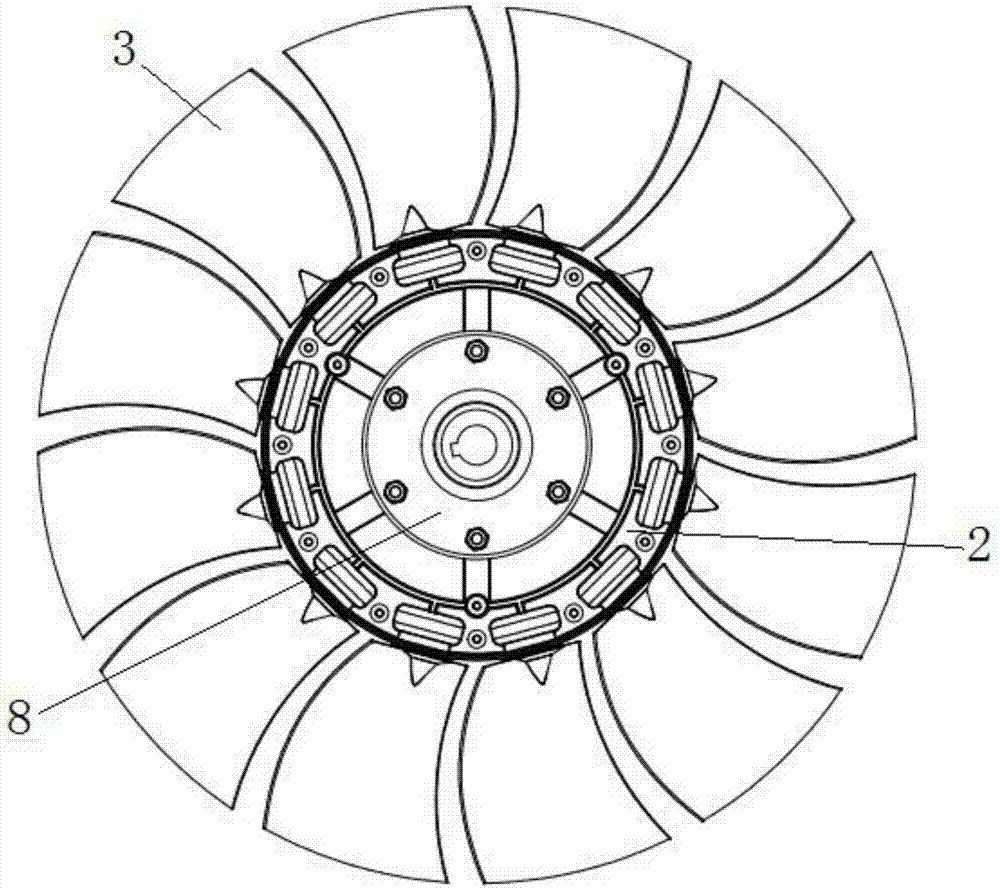

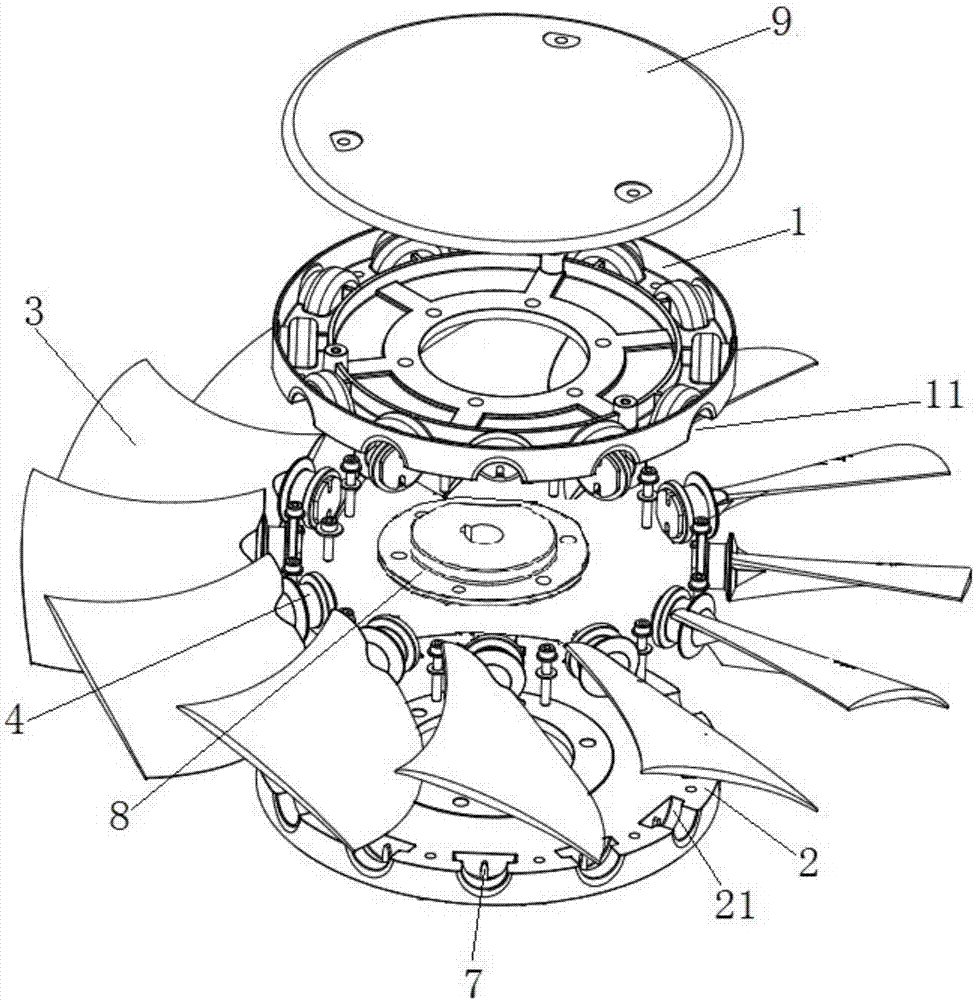

[0022] see Figure 1 ~ Figure 3 The split impeller comprises hub one 1, hub two 2 and several blades 3 respectively connected and arranged between the edge of hub one and hub two, and each blade is symmetrically distributed on the radial periphery of hub one and hub two, The root of the blade is provided with a mounting column 4 for connecting the hub 1 and the hub 2, and the edges of the hub 1 and the hub 2 are respectively provided with a positioning groove 11 and a positioning groove 2 21, and the positioning groove 1 and the positioning groove 2 are docked (along the hub 1 and the hub 2). The axial direction of the second butt joint) can be partially or completely fitted and matched with the outer cylindrical surface of the installation column, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com