Hydraulic system channel body radial sealing device

A radial sealing and hydraulic system technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the leakage of the connection surface of the channel body, reduce the roughness of the connection surface of the channel body, tighten the bolt installation torque requirements, etc., and achieve reduction Surface roughness requirements, effects of achieving leak-free connections, strong flexibility and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

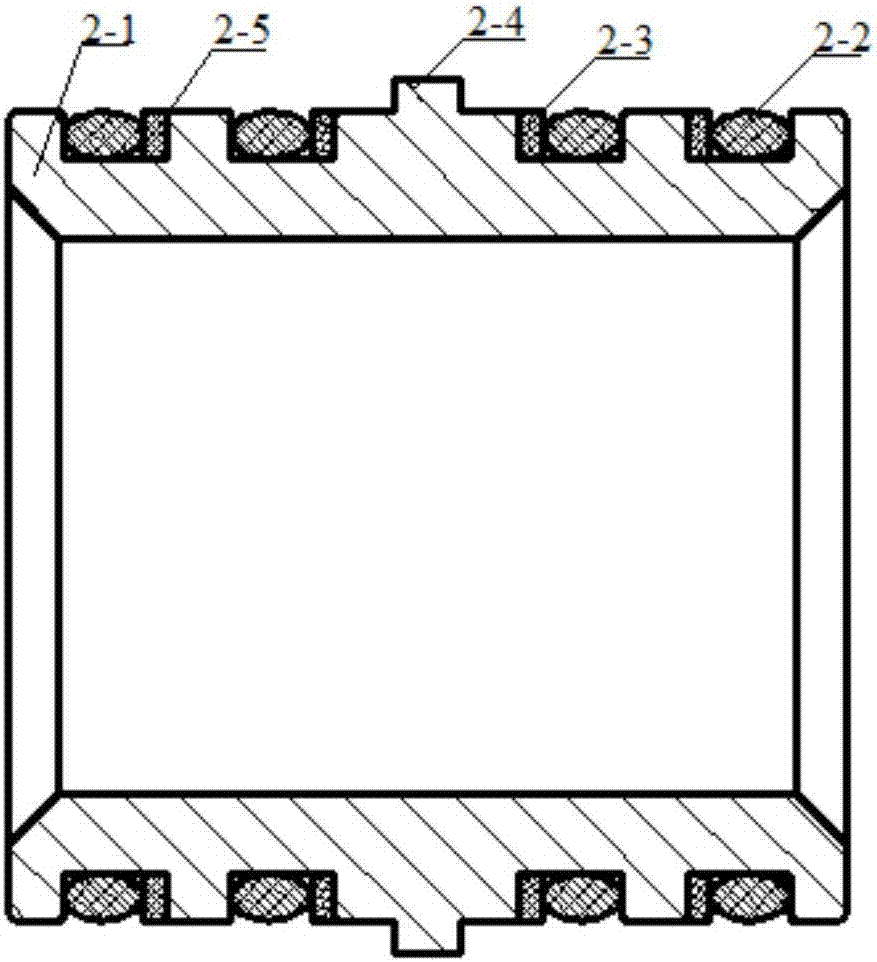

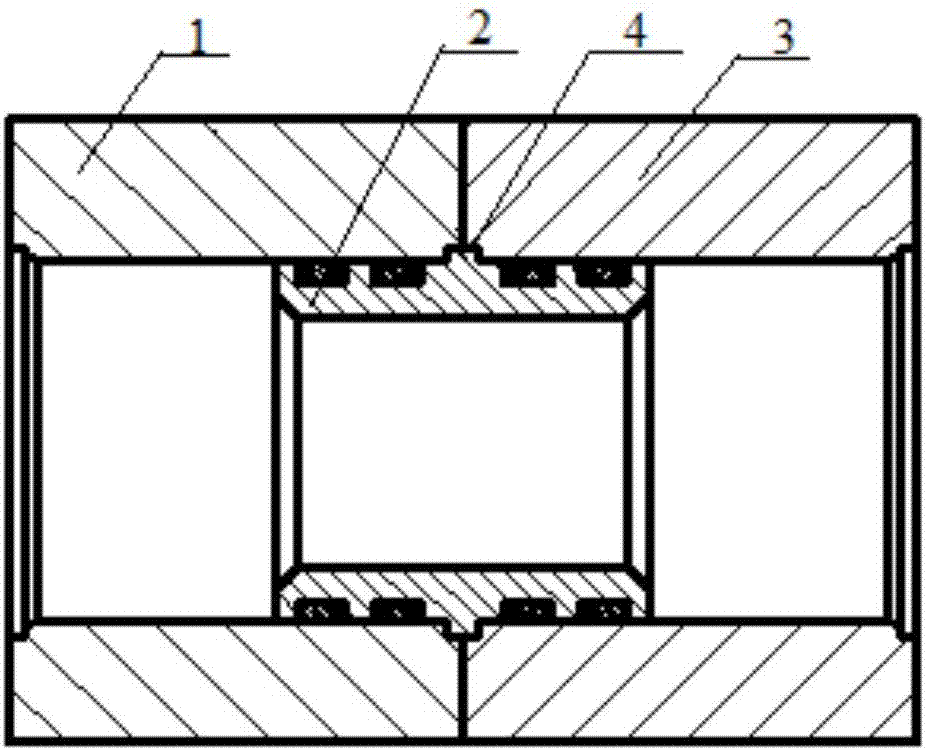

[0041] When the radial seal straight-through hydraulic joint 2 is used to connect two (not limited to two) unidirectional channel bodies, the inner diameter of the oil port of the channel body A1 and channel body B3 to be sealed connected is the same as the outer diameter of the radial seal hydraulic joint 2 Diameter size matching, and a sinking groove with a diameter 0.1mm-0.2mm larger than the outer diameter of the shoulder 2-4 and a depth of 0.1mm-0.2mm larger than half the width of the shoulder 2-4 is designed on the end face of the oil port, and the radial seal is directly connected to the hydraulic joint 2 Insert into the oil port of the channel body A1 until the end surface of the shoulder 2-4 fits with the end surface of the sinking groove 4 at the oil port of the channel body A1; at the same time, insert the oil port of the channel body B into the other side of the radial seal straight-through hydraulic joint 2 , until the other end surface of the shoulder 2-4 fits wit...

Embodiment 2

[0043]When the radial seal straight-through hydraulic joint 2 is used to seal the oil inlet channel and the oil return channel of the hydraulic system at the same time, that is, when two (not limited to two) bidirectional channel bodies are connected, the channel body A1 and the channel body that need to be sealed are connected The inner diameter of the oil port connected to the body B3 matches the outer diameter of the radial seal hydraulic joint 2, and the diameter of the oil port end surface is designed to be 0.1mm to 0.2mm larger than the outer diameter of the shoulder 2-4, and the depth is 0.1mm larger than half the width of the shoulder 2-4 mm~0.2mm sinking groove, insert two radial seal straight through hydraulic joints 2 into the oil inlet channel and oil return channel oil port of channel body A1 respectively until the end surface of shoulder 2-4 is in contact with the oil inlet channel and return channel of channel body A1 The end faces of the sinking groove 4 at the ...

Embodiment 3

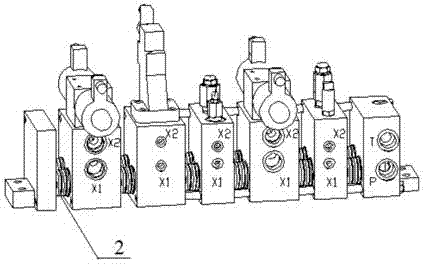

[0045] The radial seal straight-through hydraulic joint adopts the radial seal form of O-ring + retaining ring installed in the two seal ring grooves 2-5 to realize the reliable sealing of the oil ports connected to multiple channel bodies in parallel. The number and relative position of the channel bodies can be adjusted. Adjustment can realize the leak-free connection of the oil ports between the channel bodies. Through this connection mode, the design of parallel multi-piece channel bodies has strong flexibility and versatility.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com