Pressure transducer and manufacturing method thereof, and electronic device

The technology of a pressure sensor and a manufacturing method is applied to the fluid pressure measurement using optical methods, instruments, and the measurement of force by measuring the change of optical properties of materials when they are stressed. Simple process and low driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

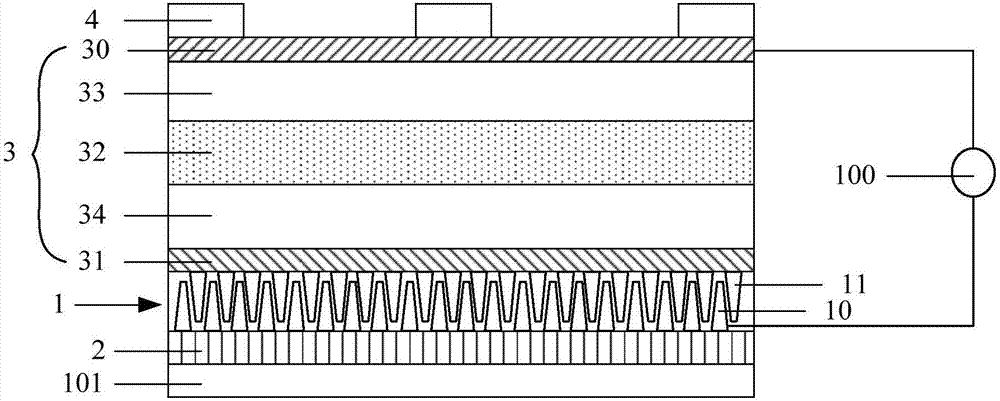

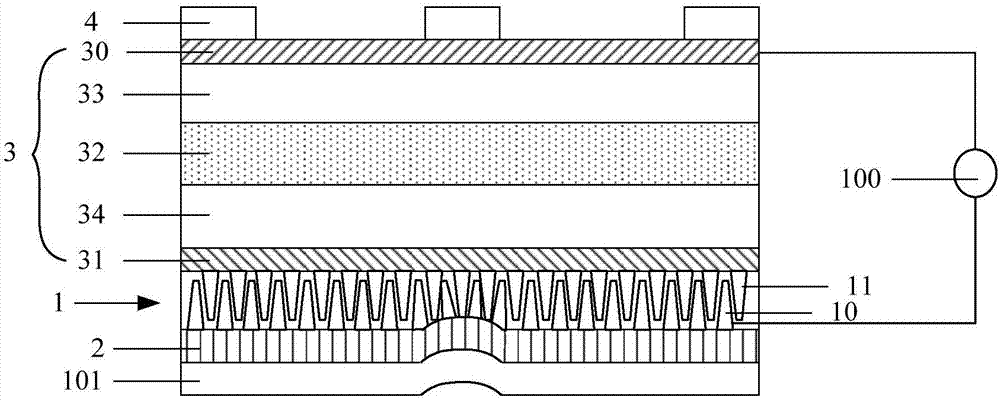

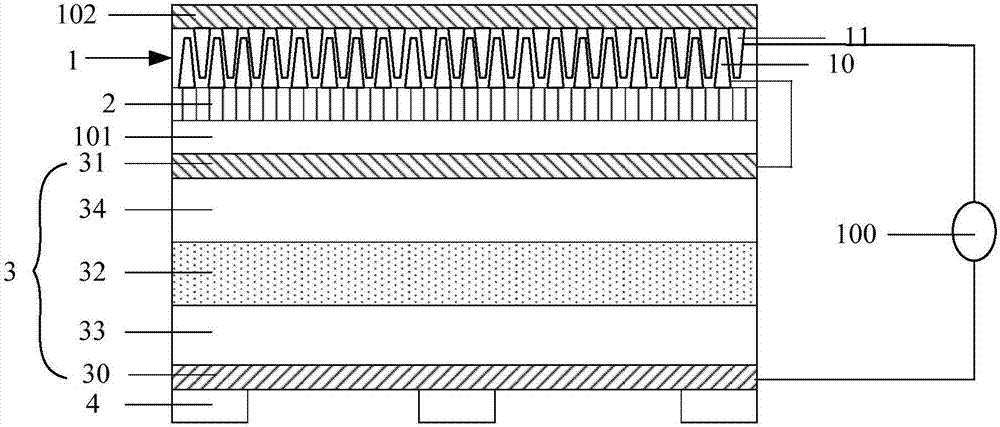

[0079] combine figure 1 and figure 2 As shown, the electroluminescent device of the pressure sensor in this embodiment is an organic light emitting diode, which makes the pressure sensor flexible. The pressure sensor specifically includes:

[0080] The organic light emitting diode 3 includes a first electrode 30, a second electrode 31, and an organic light emitting layer 32 disposed between the first electrode 30 and the second electrode 31, wherein the materials of the first electrode 30 and the second electrode 31 can be Select metal materials, such as: Cu, Al, Ag, Mo, Cr, Nd, Ni, Mn, Ti, Ta, W and other metals and alloys of these metals, the first electrode 30 and the second electrode 31 can be a single-layer structure or Multi-layer structure, multi-layer structure such as Cu\Mo, Ti\Cu\Ti, Mo\Al\Mo, etc. The material of the first electrode 30 and the second electrode 31 can also be a conductive polymer. The material of the organic light-emitting layer 32 can be select...

Embodiment 2

[0115] Based on the same inventive concept, a method for manufacturing a pressure sensor is provided in this embodiment, including:

[0116] forming an electroluminescent device, including the steps of forming a first electrode, a second electrode, and an electroluminescent layer between the first electrode and the second electrode;

[0117] Forming a resistance layer, the first electrode and the resistance layer are respectively connected to two poles of a power supply to form a loop;

[0118] Forming a photoelectric sensor, the resistance layer is deformed under the influence of pressure, causing the resistance of the resistance layer to change, thereby changing the brightness of the electroluminescence device, and the photoelectric sensor is used to obtain Parameters related to the brightness change of the device;

[0119] A detection unit is provided, connected with the photoelectric sensor, and the detection unit is used to determine the magnitude of the applied pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com