Low-torque ripple built-in permanent magnet motor rotor and method for optimizing magnetic flux density of motor

A permanent magnet motor and torque fluctuation technology, which is applied in the manufacture of motor generators, magnetic circuit rotating parts, magnetic circuits, etc., can solve the problem of poor air gap flux density waveform quality, additional cost, and increased stator core and Problems such as rotor core harmonic loss can be achieved to reduce vibration and noise, reduce cogging torque, and reduce harmonic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

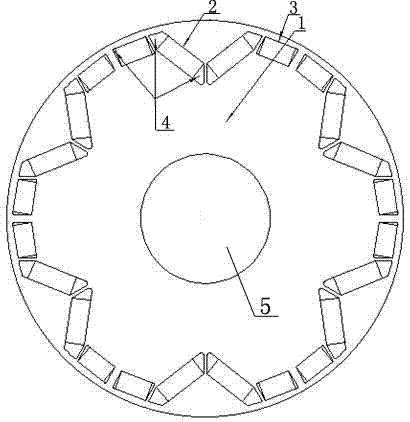

[0023] Embodiment one, with reference to the attached figure 1 .

[0024] A low-torque-fluctuation built-in permanent magnet motor rotor, including a rotor core 1, a permanent magnet, an M-shaped magnetic steel slot 4 and a rotating shaft 5, the permanent magnet is arranged on the rotor core, and the permanent magnet under one magnetic pole is composed of two The one-shaped permanent magnet 3 and one V-shaped permanent magnet 2 are composed, one V-shaped permanent magnet 2 is located in the middle, two in-shaped permanent magnets 3 are respectively located on both sides of the V-shaped permanent magnet 2, and the M Type magnetic circuit structure; 2p M-shaped magnetic steel slots 4 are evenly distributed in a ring on the entire rotor core 1, where p is the number of pole pairs of the permanent magnet motor, two in-line permanent magnets 3 and one V-shaped permanent magnet 2 Set in the M-shaped magnetic steel groove 4. 2p M-shaped magnetic steel slots 4 are evenly distributed...

Embodiment 2

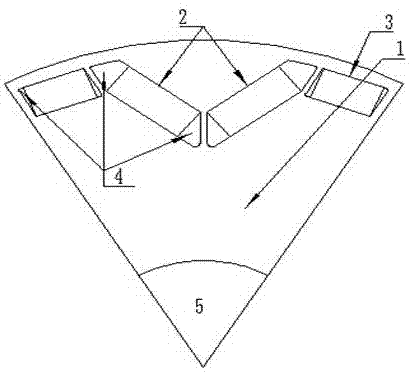

[0031] Embodiment two, referring to the attached figure 2 .

[0032] In this embodiment, the M-shaped magnetic steel groove 4 is composed of four sections, two inline permanent magnets 3 are located in the two sections on both sides, and a V-shaped permanent magnet 2 is located in the middle two sections. The slots are intermittent between segments.

Embodiment 3

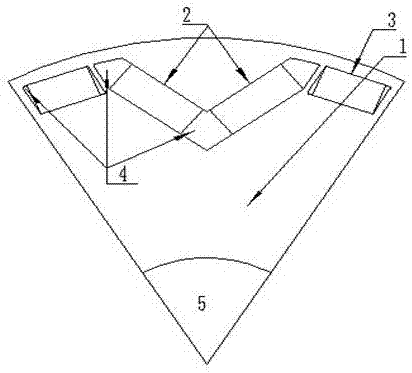

[0033] Embodiment three, with reference to the attached image 3 .

[0034] In this embodiment, the M-shaped magnetic steel groove 4 is composed of four sections, two inline permanent magnets 3 are located in the two sections on both sides, a V-shaped permanent magnet 2 is located in the middle two sections, and two inline permanent magnets 3 are located in the middle two sections. The paragraphs are intermittent and independent, and the middle two paragraphs are continuous, forming a complete V-shape together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com