Micro-alloying spot welding process distance-adjustable alloy powder roller coating equipment

A micro-alloying and alloy powder technology is applied in the field of micro-alloy spot welding process-adjustable alloy powder roller coating equipment. Accurate and controllable thickness, improved spot welding quality and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

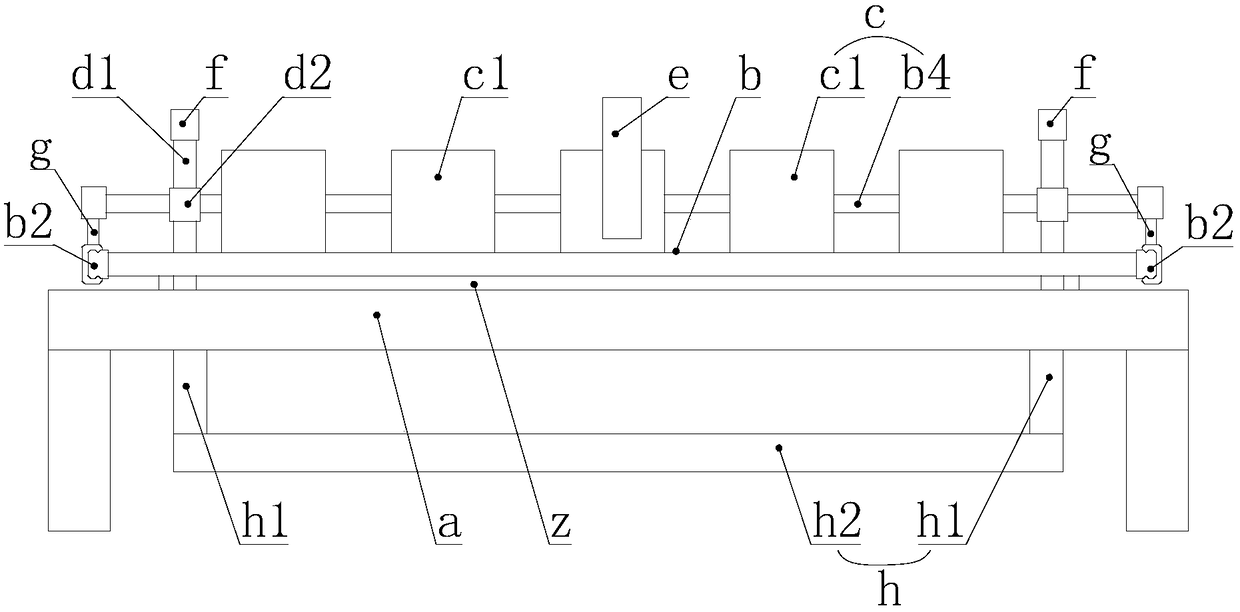

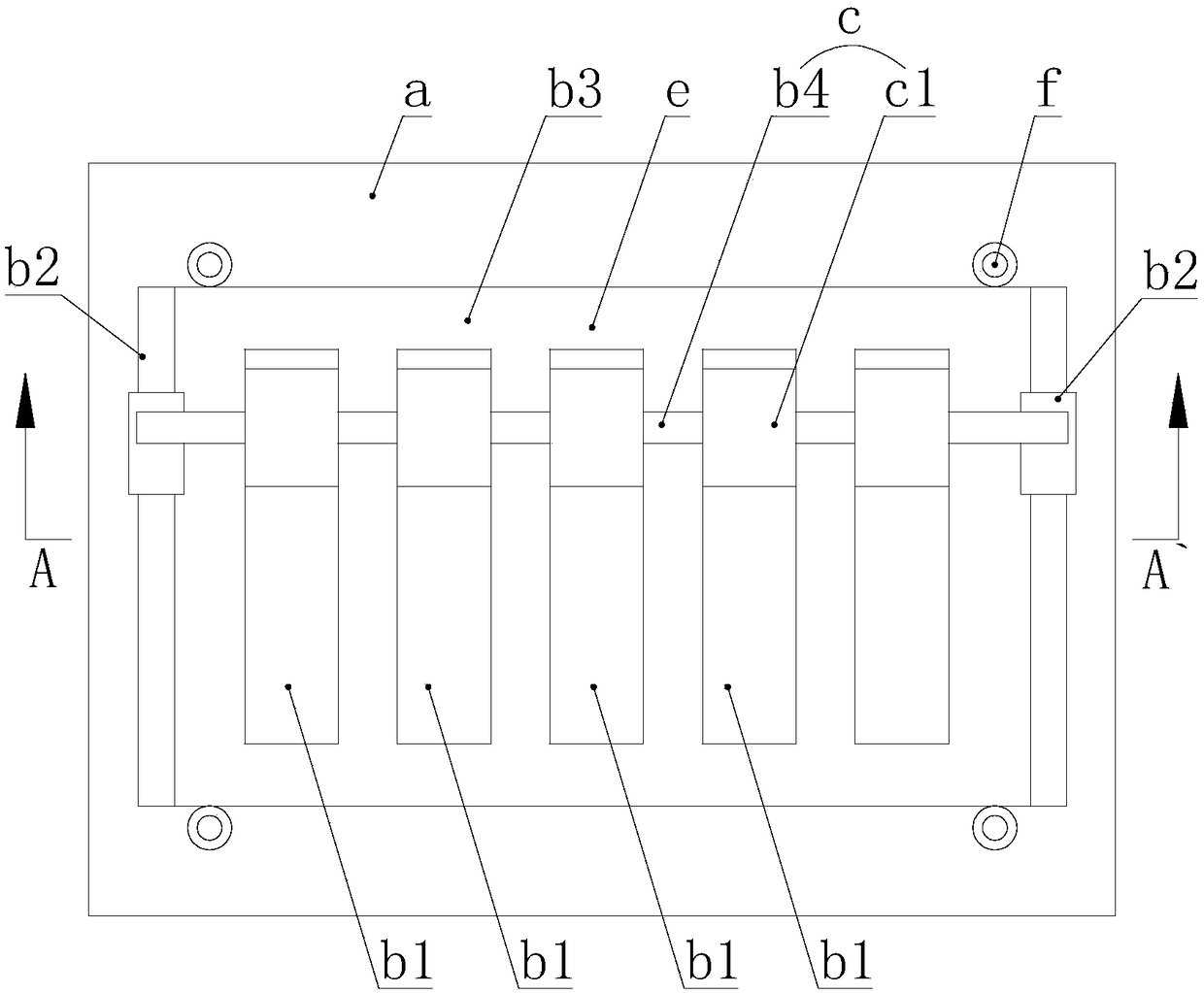

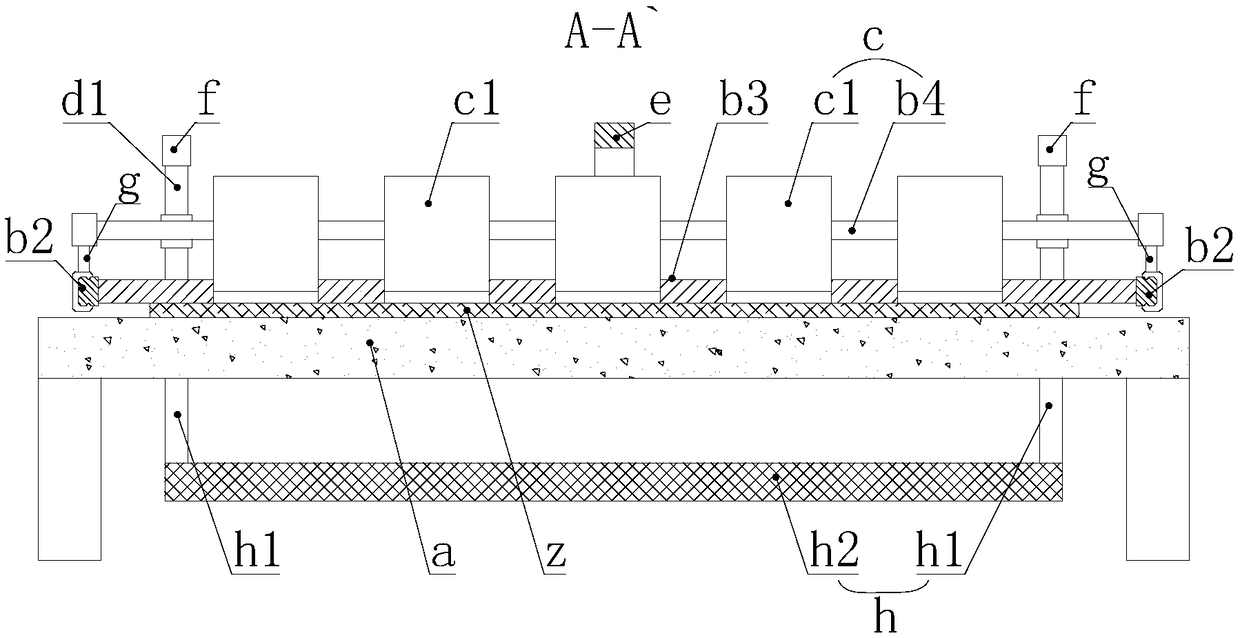

[0028] Such as Figure 1 to Figure 7 As shown, a micro-alloying spot welding process distance-adjustable alloy powder roller coating equipment includes a base a, a lifting and pressing seat b is arranged above the base a, and a roller coating groove b1 is opened on the lifting and pressing seat b. A linear sliding piece b2 parallel to the roller coating groove b1 is fixed on the lifting and pressing seat b, and a lifting coating roller assembly c is fixed on the linear sliding piece b2, and the lifting coating roller assembly c extends into The roller coating tank b1, the lifting coating roller assembly c rolls along the rolling coating tank b1, and a distance adjusting device g is provided between the lifting pressing seat b and the lifting coating roller assembly c.

[0029] The lifting and pressing seat b includes a pressing seat b3, and the pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com