Chipboard hot-pressing method

A hot-pressing method and particleboard technology, applied in the field of particleboard hot-pressing, can solve the problems of high free formaldehyde content in finished boards, low hot-pressing work efficiency, large adhesive consumption, etc., to achieve stable product quality, high production efficiency, The effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

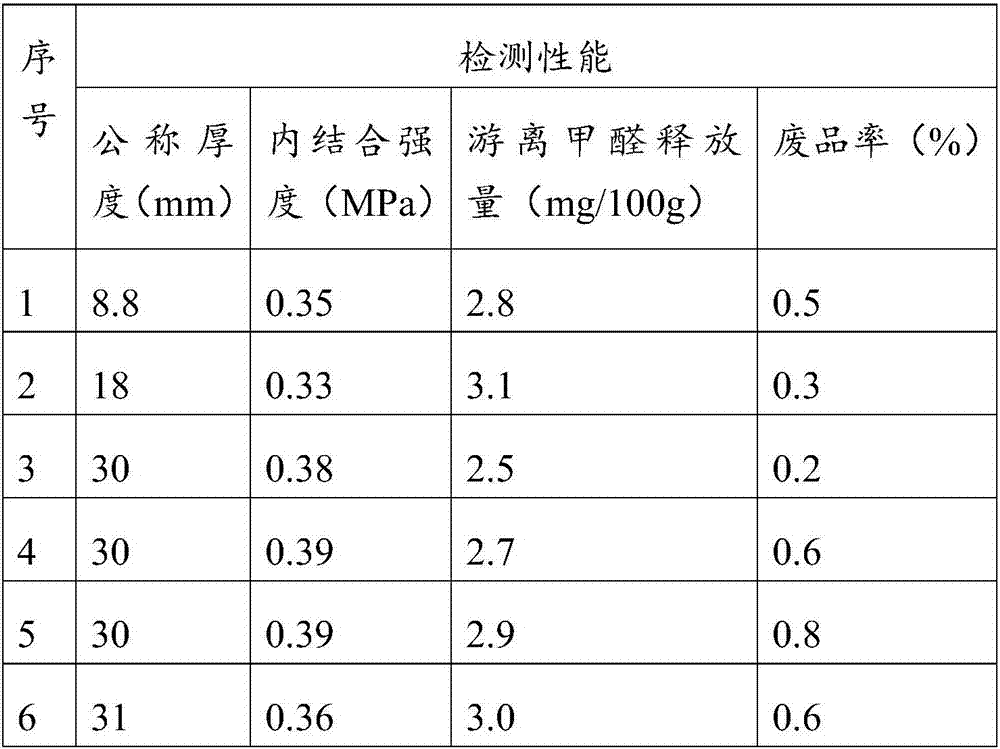

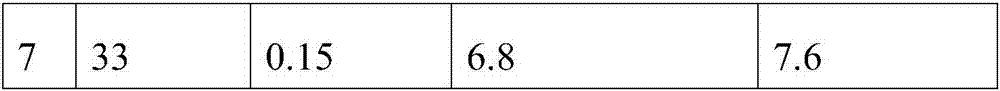

Examples

Embodiment 1

[0023] A method for hot-pressing particle boards, which adopts the method of hot-pressing with a continuous flat-pressing hot-pressing machine. The pre-pressed slabs are sequentially passed through a high-pressure hot-pressing zone, a low-pressure hot-pressing zone, and a secondary pressurized hot-pressing zone. The hot pressing pressure of the zone is 1.5N / mm 2 , the hot-pressing temperature is 220°C; the hot-pressing pressure in the low-pressure hot-pressing zone is 1.0N / mm 2 , the hot-pressing temperature is 210°C; the hot-pressing pressure in the secondary pressing hot-pressing zone is 0.8N / mm 2 , the hot-pressing temperature is 190° C.; the hot-pressing factor is 4.5 s / mm.

[0024] The slab is a three-layer structure slab paved with two layers of surface fine shavings and a layer of core layer coarse shavings, the moisture content of the surface fine shavings is 10.5%, and the moisture content of the core layer coarse shavings is 5.5%; The fine shavings in the surface l...

Embodiment 2

[0026] A method for hot-pressing particle boards, which adopts the method of hot-pressing with a continuous flat-pressing hot-pressing machine. The pre-pressed slabs are sequentially passed through a high-pressure hot-pressing zone, a low-pressure hot-pressing zone, and a secondary pressurized hot-pressing zone. The hot pressing pressure of the zone is 4.5N / mm 2 , the hot-pressing temperature is 230°C; the hot-pressing pressure in the low-pressure hot-pressing zone is 3.2N / mm 2 , the hot-pressing temperature is 225°C; the hot-pressing pressure in the secondary pressing hot-pressing zone is 2.5N / mm 2 , the hot-pressing temperature is 195° C.; the hot-pressing factor is 6.4 s / mm.

[0027] The slab is a three-layer structure slab paved with two layers of surface layer fine shavings and a layer of core layer coarse shavings, the moisture content of the surface layer fine shavings is 11.5%, and the moisture content of the core layer coarse shavings is 6.0%; The fine shavings in t...

Embodiment 3

[0029] A method for hot-pressing particle boards, which adopts the method of hot-pressing with a continuous flat-pressing hot-pressing machine. The pre-pressed slabs are sequentially passed through a high-pressure hot-pressing zone, a low-pressure hot-pressing zone, and a secondary pressurized hot-pressing zone. The hot pressing pressure in the zone is 3.0N / mm 2 , the hot-pressing temperature is 225°C; the hot-pressing pressure in the low-pressure hot-pressing zone is 2.2N / mm 2 , the hot-pressing temperature is 215°C; the hot-pressing pressure in the secondary pressing hot-pressing zone is 1.25N / mm 2, the hot-pressing temperature is 190° C.; the hot-pressing factor is 5.2 s / mm. The pressure of preloading is 1.2MPa.

[0030] The slab is a three-layer structure slab paved with two layers of surface fine shavings and a layer of core layer coarse shavings, the moisture content of the surface fine shavings is 10.5%, and the moisture content of the core layer coarse shavings is 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com