Fully-automatic plastic batching device

A fully automatic, plastic technology, applied in the field of plastic production equipment, can solve the problems of no error-proofing device, full automation, and large workshop space requirements, so as to prevent the problem of wrong material distribution, improve traceability, and occupy a small space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

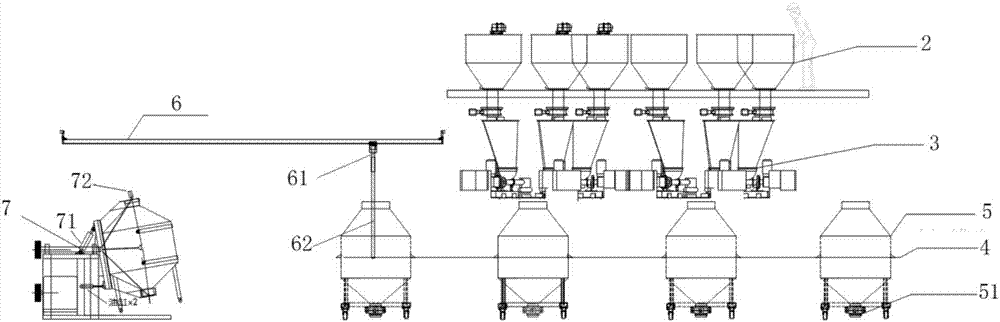

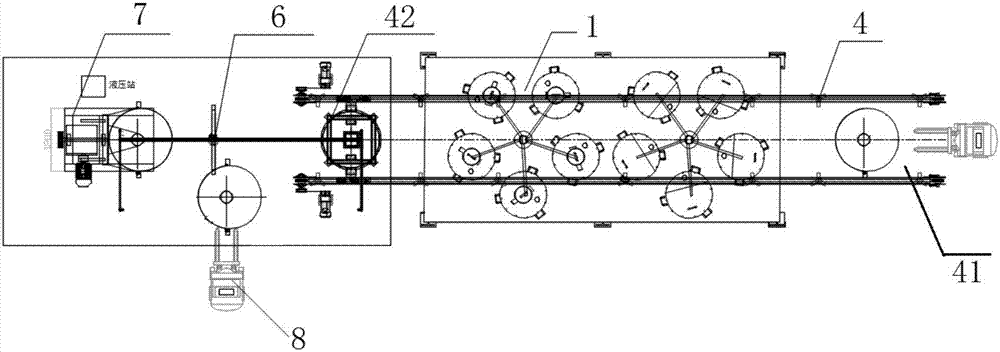

[0029] see figure 1 with figure 2 , a fully automatic plastic batching device according to the present invention, comprising a weight-reducing scale batching area 1, a number of storage bins 2 are placed in the weight-loss scale batching area 1, and raw materials are placed in the storage bins 2 A weight loss scale 3 is installed at the bottom outlet of the storage bin 2, and the weight loss scale 3 measures and transports the raw materials placed in the storage bin 2 into the mobile hopper 5 through the discharge port;

[0030] The bottom of described weight-reducing scale 3 is provided with the chain double-track conveying line 4 that runs through horizontally, and one end of described chain double-track conveying line 4 is set as inlet end 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com