A method for avoiding conflicts between cranes and unmanned multi-day workshops

An unmanned and overhead crane technology, applied in transportation and packaging, load hoisting components, safety devices, etc., can solve the problems of overhead crane conflicts, unreasonable avoidance strategies, low operation efficiency, etc., and reduce conflicts and emergency stops. Probability, shorten the downtime, and improve the efficiency of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

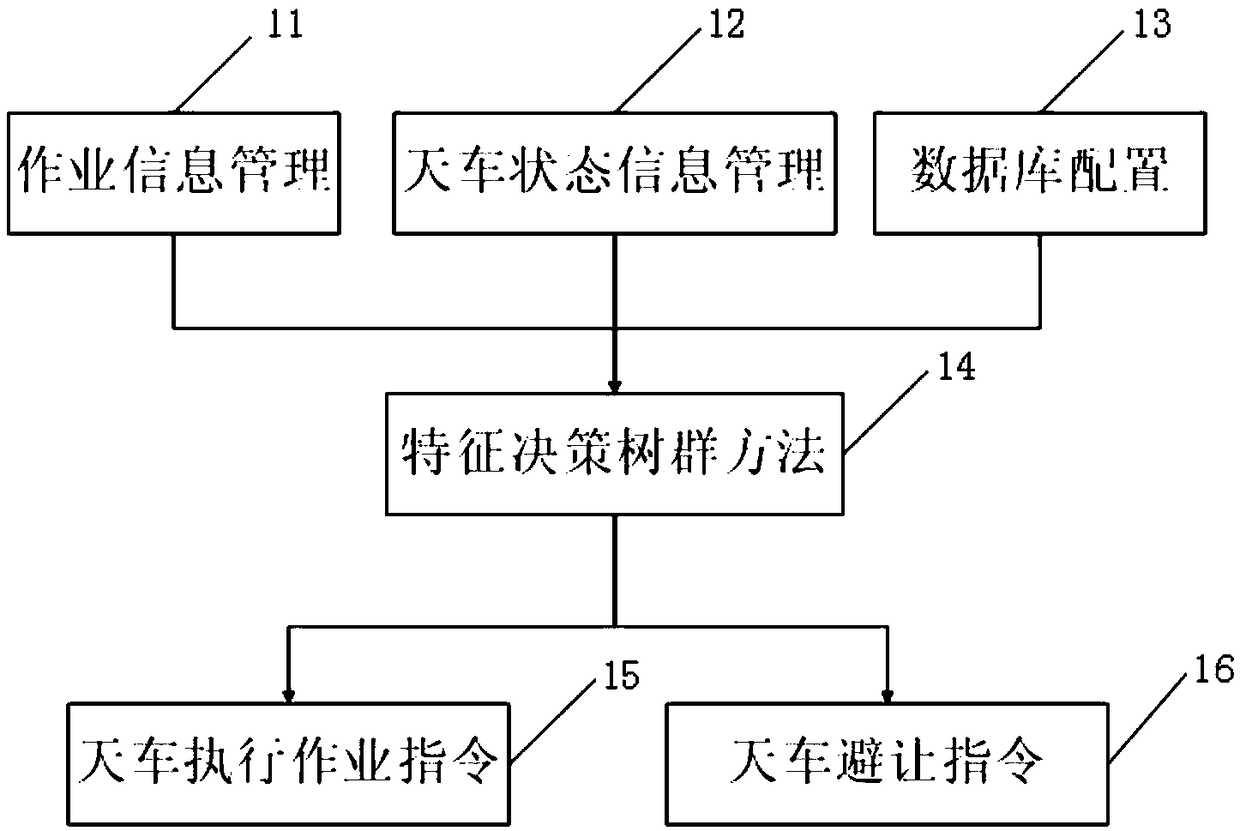

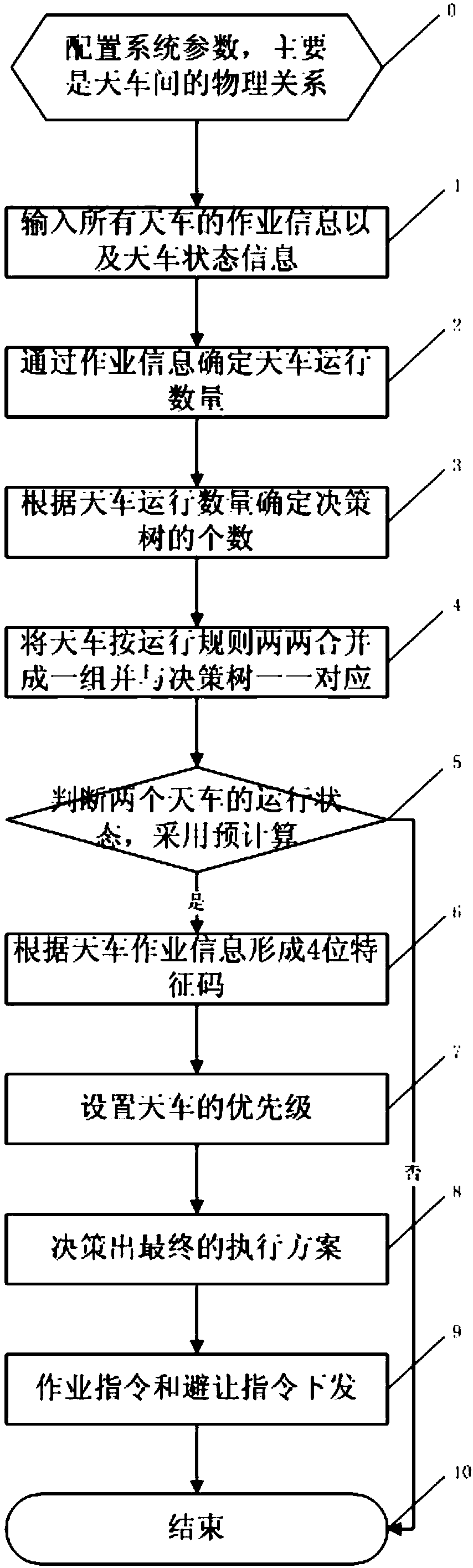

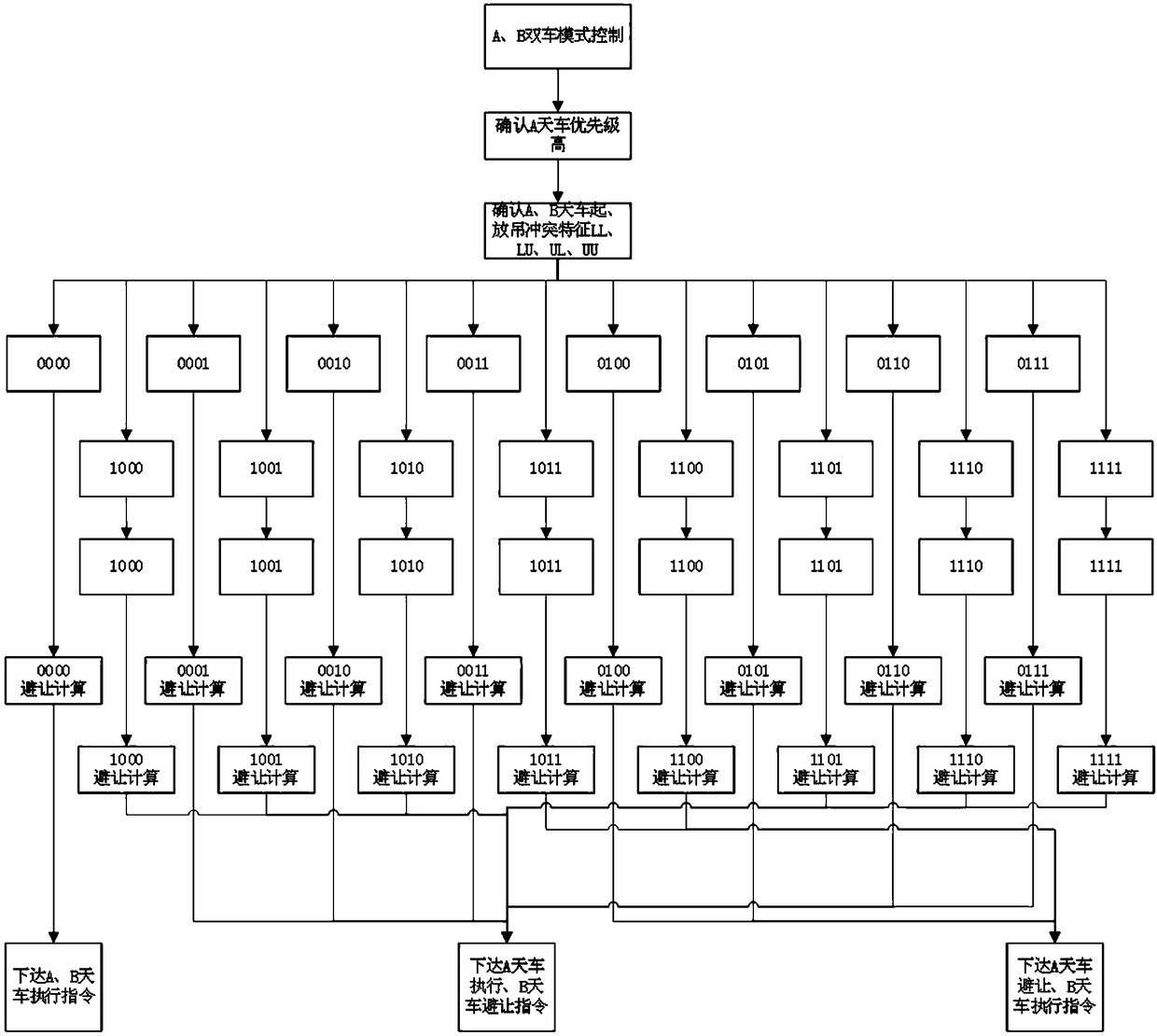

[0015] A method for avoiding conflicts in multi-day workshops with unmanned cranes, which communicates with the unmanned system of the crane, receives input from the unmanned system of the crane, and sends operation instructions to the unmanned system of the crane at the same time; through calculation Merge the cranes into a group according to the operation rules and correspond to the decision tree one by one (4), judge the operating status of the two cranes, and determine whether to use pre-calculation or process control (5), judge the lifting according to the operation information of the cranes Whether there is a conflict, whether lifting and lowering conflicts, whether lifting and lowering conflicts, whether lifting and lowering conflicts, and finally form a 4-digit feature code (6). According to the current state of the two-day crane and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com