Aerobic fermentation device for kitchen garbage

A kitchen waste and fermentation device technology, applied in fertilization devices, organic fertilizers, organic fertilizer equipment and other directions, can solve the problems of large influence of the stack-type composting effect, air pollution, slow fermentation speed, etc., and reduce odor. The effect of generating and escaping, reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described with reference to the accompanying drawings.

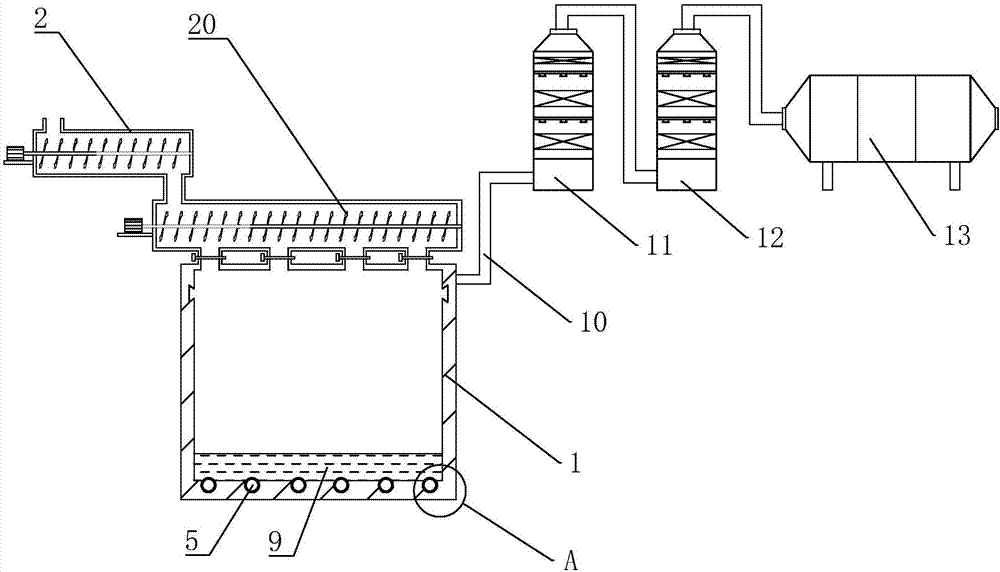

[0040] Such as figure 1 As shown, an aerobic fermentation device for kitchen waste includes a fermentation tank 1 and a material conveyor 2 for feeding materials into the fermentation tank 1 .

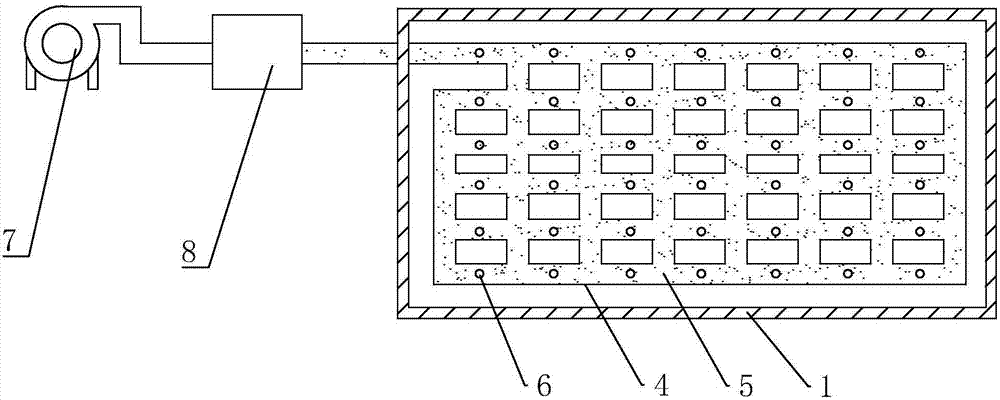

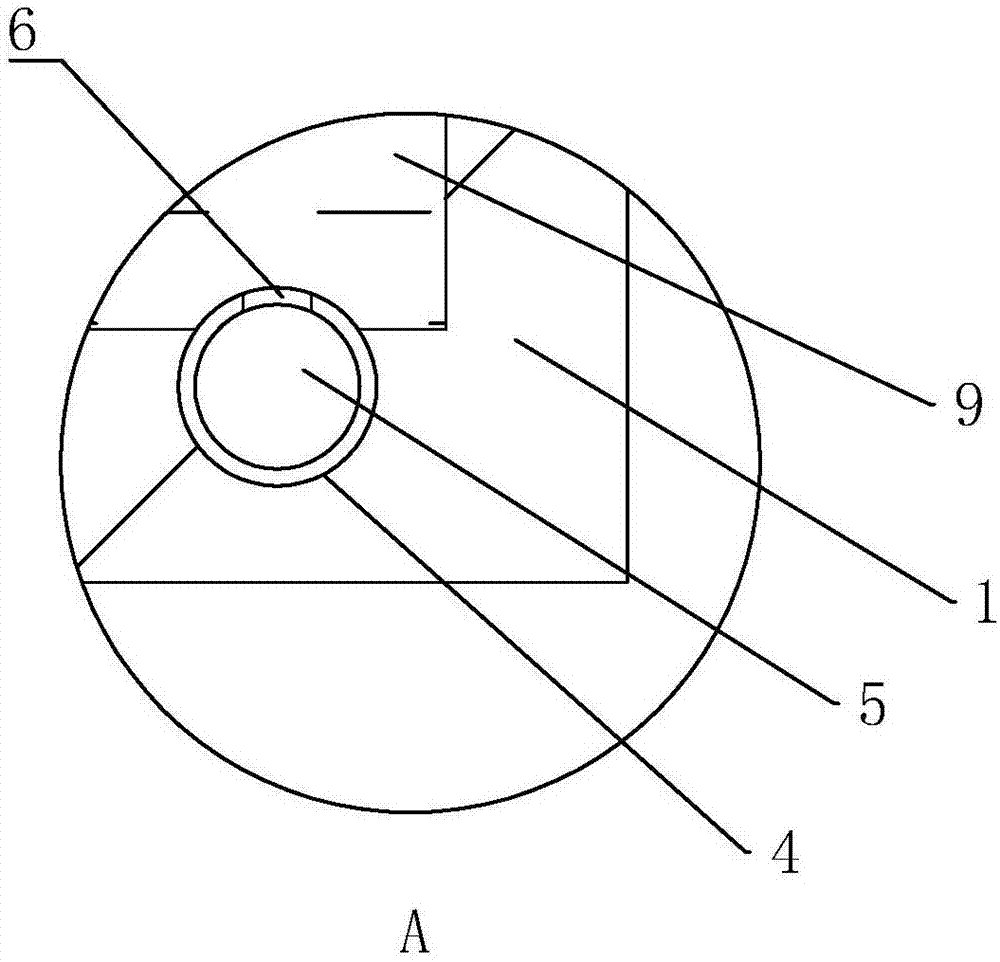

[0041] Such as figure 1 As shown, the fermentation tank 1 is a closed chamber. Such as figure 2 with image 3 As shown, the bottom surface of the fermentation tank 1 is provided with a net-shaped dark ditch 4, and an oxygen supply pipe 5 is embedded in the dark ditch 4, and a plurality of oxygen holes 6 are provided on the upper surface of the oxygen supply pipe 5. The oxygen supply pipes 5 communicate with each other, and one end of one of the oxygen supply pipes 5 is provided with an air supply pump 7 , and a heater 8 is installed on the oxygen supply pipe 5 . The air supply pump 7 draws the air heated to a certain level by the heater 8 into the oxygen supply pipe 5, and then d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com