Device and method for continuously producing aluminum sulfate octahydrate

A technology of octadecahydrate and aluminum sulfate, applied in chemical instruments and methods, chemical/physical process, chemical/physical/physical chemical process, etc., can solve the problem of narrow metastable zone of octadecahydrate aluminum sulfate crystallization and improper crystallization operation conditions. , high temperature control requirements, to achieve the effect of easy control of particle size, short residence time and few operating parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

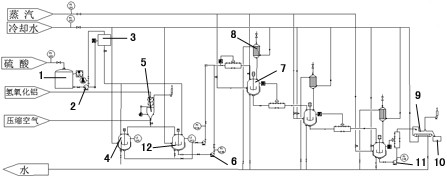

Embodiment 1

[0033] The waste sulfuric acid with a mass fraction concentration of 55% in the waste sulfuric acid tank 1 enters the head tank 3 through the sulfuric acid delivery pump 2, and the material in the head tank 3 is added to the first raw material mixing kettle 4, and the aluminum hydroxide with a mass fraction of 99.8% The powder is fed into the first raw material mixing tank 4 through the solid feeding pocket 5 and mixed with waste sulfuric acid to form a raw material slurry. The molar feeding ratio of aluminum hydroxide and sulfuric acid is 1:1.51, and the operating temperature of the first raw material mixing tank 4 is 35°C. The feeding time is 2 hours, and the stirring time is 2 hours. Three reaction kettles 7 are used in series for normal pressure reaction, and the reaction kettle 7 is fed with steam for reaction: the temperature of the first reaction kettle is 95°C, and the residence time is 60min (the conversion rate of the product is 72% ), the temperature of the intermedi...

Embodiment 2

[0035]The waste sulfuric acid with a mass fraction concentration of 55% in the waste sulfuric acid tank 1 enters the head tank 3 through the sulfuric acid delivery pump 2, and the material in the head tank 3 is added to the first raw material mixing kettle 4, and the aluminum hydroxide with a mass fraction of 99.8% The powder is fed into the first raw material mixing tank 4 through the solid feeding pocket 5 and mixed with waste sulfuric acid to form a raw material slurry. The molar feeding ratio of aluminum hydroxide and sulfuric acid is 1:1.51, and the operating temperature of the first raw material mixing tank 4 is 35°C. The feeding time is 2 hours, and the stirring time is 2 hours. Three reactors 7 are connected in series for adiabatic pressurized reaction, and the reactor 7 is fed with steam for reaction: the temperature of the first reactor is 120°C, the pressure is 0.2Mpa, and the residence time is 30min (product conversion rate 76%), the temperature of the intermediate ...

Embodiment 3

[0037] The waste sulfuric acid with a mass fraction concentration of 46% in the waste sulfuric acid tank 1 enters the head tank 3 through the sulfuric acid delivery pump 2, and the material in the head tank 3 is added to the first raw material mixing kettle 4, and the aluminum hydroxide with a mass fraction of 99.8% The powder is added to the first raw material mixing tank 4 through the solid feeding pocket 5 and mixed with waste sulfuric acid to form a raw material slurry. The molar feeding ratio of aluminum hydroxide and sulfuric acid is 1:1.49, and the operating temperature of the first raw material mixing tank 4 is 35°C. The feeding time is 1 hour, and the stirring time is 1 hour. Two reaction kettles 7 are connected in series to carry out normal pressure microwave reaction, and the reaction kettle 7 is fed with steam for reaction: the microwave power of the first reaction kettle is 200W / m 3 , the temperature is 105°C, the residence time is 30min (the product conversion rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com