Method for extracting paracumyl phenol from phenol tar

A technology for extracting p-cumylphenol and phenol, which is applied in the field of extracting p-cumylphenol, can solve the problems of maximization and failure to achieve the highest value, and achieve the effect of easy recovery and low loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

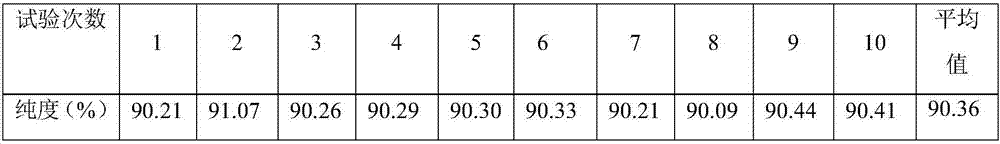

Embodiment 1

[0019] The temperature of the constant temperature bath was set to 295K, tri-n-octylamine and octylamine were mixed according to the mass ratio of 80:20, the stirring speed of the electric constant speed stirrer was controlled to be 200r / min, and the stirring time was 12min to obtain the finished extractant. The extractant was added to the key components by dropwise addition, and the rate of addition was controlled at 55 drops / min, and then the temperature was slowly raised to 313K from room temperature. In the process of heating, it was necessary to stir slowly at a uniform speed, and the heating rate was 20K per minute. The stirring speed was controlled at 120 r / min. When the temperature was raised to 290K, the solvent was added dropwise to the mixed liquid, and then the temperature was maintained at a constant temperature for 25 minutes. At this time, it was necessary to stop stirring. After 25 minutes, continue to slowly heat up and resume stirring to 313K. Start to cool do...

Embodiment 2

[0027] The temperature of the constant temperature bath was set to 295K, tri-n-octylamine and octylamine were mixed according to the mass ratio of 85:15, the stirring speed of the electric constant speed stirrer was controlled to be 200r / min, and the stirring time was 12min to obtain the finished extractant. The extractant was added to the key components by dropwise addition, and the rate of addition was controlled at 65 drops / min, and then the temperature was slowly raised to 323K from room temperature. In the process of heating, it was necessary to stir slowly at a constant speed, and the heating rate was 30K per minute. The stirring speed is controlled at 160 r / min, and the solvent is added dropwise to the mixed liquid when the temperature is raised to 300K, and the temperature is maintained at a constant temperature for 35 minutes. At this time, the stirring needs to be stopped. After 35 minutes, continue to slowly heat up and resume stirring to 323K. Start to cool down, th...

Embodiment 3

[0035] The temperature of the constant temperature bath was set to 295K, tri-n-octylamine and octylamine were mixed according to the mass ratio of 82:18, the stirring speed of the electric constant speed stirrer was controlled to be 200r / min, and the stirring time was 12min to obtain the finished extractant. The extractant was added to the key components by dropwise addition, and the rate of addition was controlled at 60 drops / M, and then the temperature was slowly raised to 323K from room temperature. Add 10 ml of tri-n-octylamine solution dropwise to the mixed liquid at 295K, then keep the temperature at a constant temperature for 30 minutes, stop stirring at this time, continue to slowly heat up and resume stirring to 323K after 30 minutes, start cooling after the heating process, and the cooling rate Control the decrease of 25K per minute, until it drops to 283K, add 10 ml of tri-n-octylamine solution dropwise again, stand still for 20 minutes, and stir again for 10 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com