Patents

Literature

38 results about "Tri-N-octylamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trimethylaluminium preparation method

InactiveCN104774219ASave materialHigh yieldGroup 3/13 element organic compoundsEtherCoordination complex

A trimethylaluminium preparation method includes the steps of adding aluminium-magnesium alloy powder and ethers into a reactor under the protection of inert gas, dropwise adding alkyl halide under the stirring condition, keeping ether backflow in the dropwise alkyl halide adding process, continuing to keep the ether backflow for 4 hours to 5 hours after alkyl halide is dropwise added, regulating the temperature of the reactor to 45 DEG C to 100 DEG C, keeping the temperature for 1 hour to 4 hours, evaporating the ethers, regulating the temperature of the reactor to 45 DEG C to 70 DEG C, keeping the temperature, evaporating the coordination compound of trimethylaluminium and the ethers under the vacuum condition, moving the coordination compound of the trimethylaluminium and the ethers to a deolation kettle, adding tri-n-octylamine, conducting heating and backflow under the stirring condition, keeping for 2 hours to 3 hours, regulating the temperature of the deolation kettle to 85 DEG C to 89 DEG C again, keeping the temperature for 8 hours to 10 hours under the vacuum degree of 1 mmHg to 50 mmHg, evaporating the ethers, raising the temperature of the deolation kettle to 90 DEG C to 160 DEG C, keeping the temperature for 30 hours to 35 hours under the vacuum condition, and evaporating the trimethylaluminium.

Owner:HENAN CHENGMING PHOTOELECTRIC NEW MATERIAL CO LTD

Preparation method of high-purity trimethyl aluminum

ActiveCN104774218AEasy to operateImprove the purification effectGroup 3/13 element organic compoundsStationary phasePurification methods

The invention relates to a preparation method of high-purity trimethyl aluminum, belonging to the technical field of preparation of compounds of Group 3 metals in the periodic table. The preparation method comprises the following steps: (1) preparing a trimethyl aluminum crude product by using aether as a solvent; and (2) purifying the trimethyl aluminum crude product obtained in the step (1), wherein a first chromatographic column is utilized to purify the trimethyl aluminum crude product and adopts grafted silicon dioxide as a stationary phase, and the grafted silicon dioxide is silicon dioxide with tri-n-octyl amine grafted on the surface. The preparation method adopts the two steps of synthesis and separation to obtain the trimethyl aluminum of which the purity can reach 6N. The purification method combines the solid-liquid separation means to load the specific complexant onto the silicon dioxide; and thus, the method is simple to operate and further enhances the purification effect.

Owner:苏州普耀光电材料有限公司

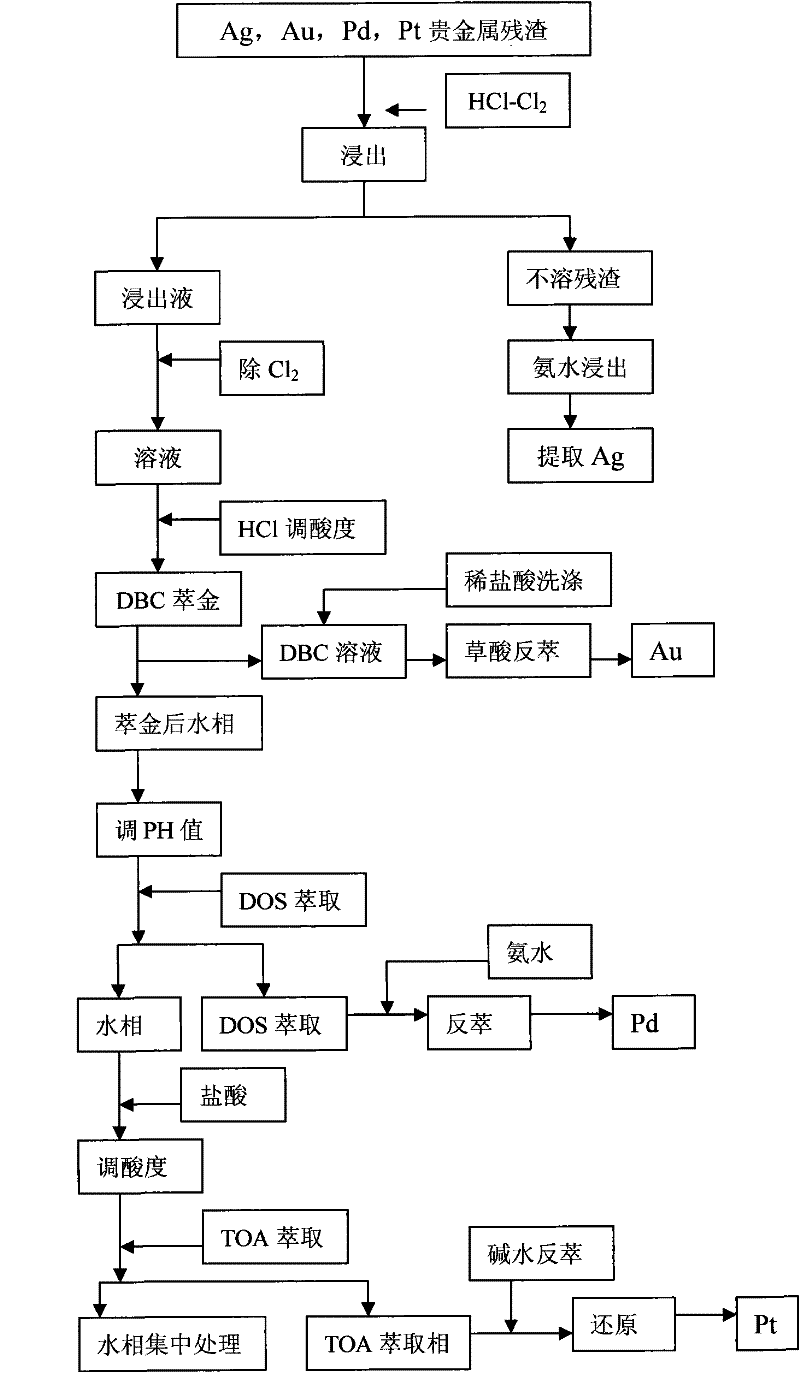

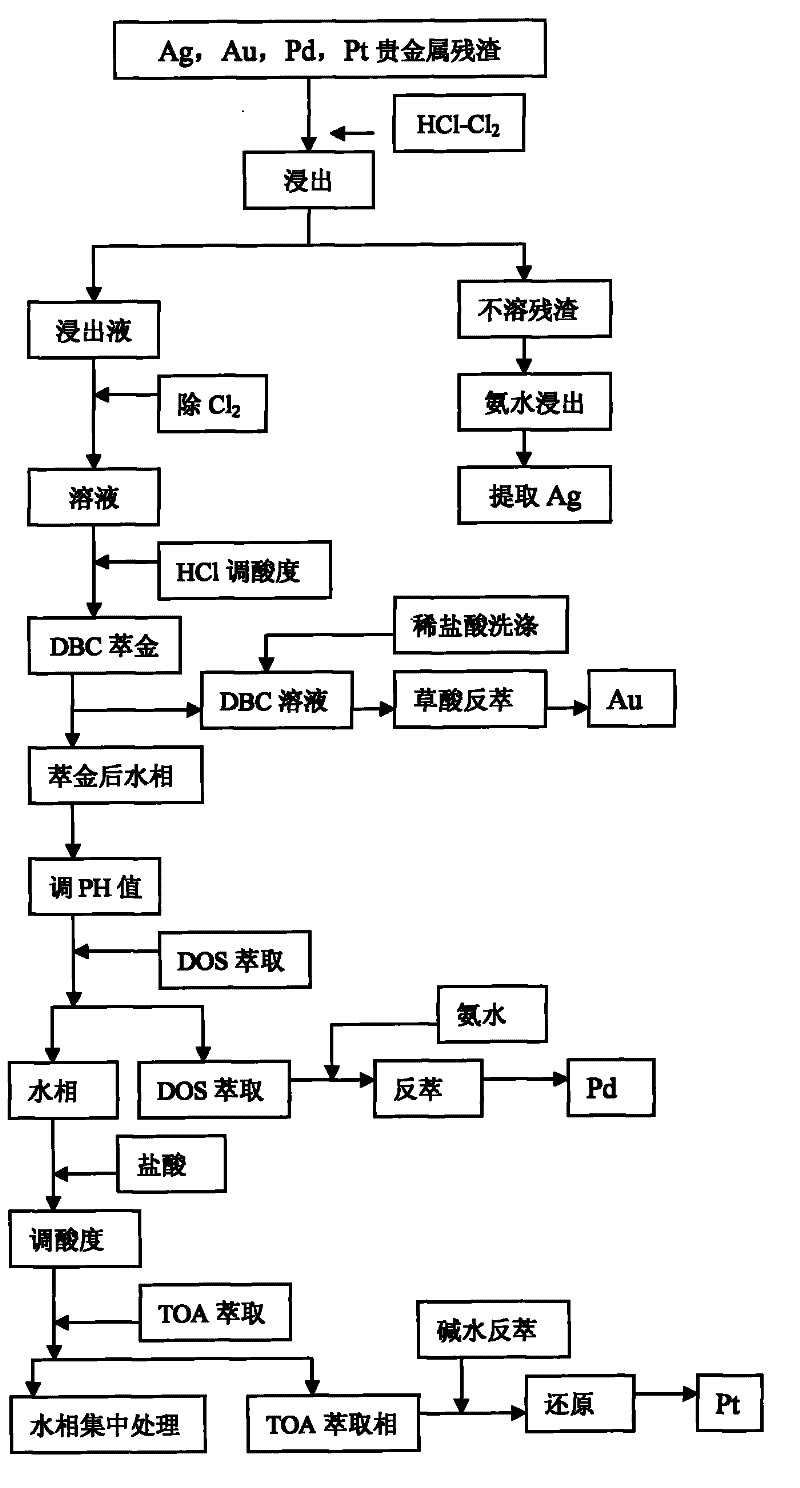

Process for extracting, separating and purifying Ag, Au, Pd and Pt

The invention relates to a process for extracting, separating and purifying Ag, Au, Pd and Pt. The process comprises the following steps of: precipitating and separating Ag in the form of AgC1, then adding ammonia water for dissolving, reducing hydrazine hydrate to obtain Ag; extracting by using dibutyl carbitol, and back-extracting Au with 5 percent of oxalic acid with a direct acceptance rate of more than or equal to 99.9 percent; extracting Pd with n-octyl sulfur ether, wherein the extraction rate of palladium is more than or equal to 99.99 percent, and then back-extracting the palladium with 3mol / L ammonia water; and finally, extracting Pt with tri-n-octylamine, back-extracting platinum with alkaline water and reducing to obtain platinum.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

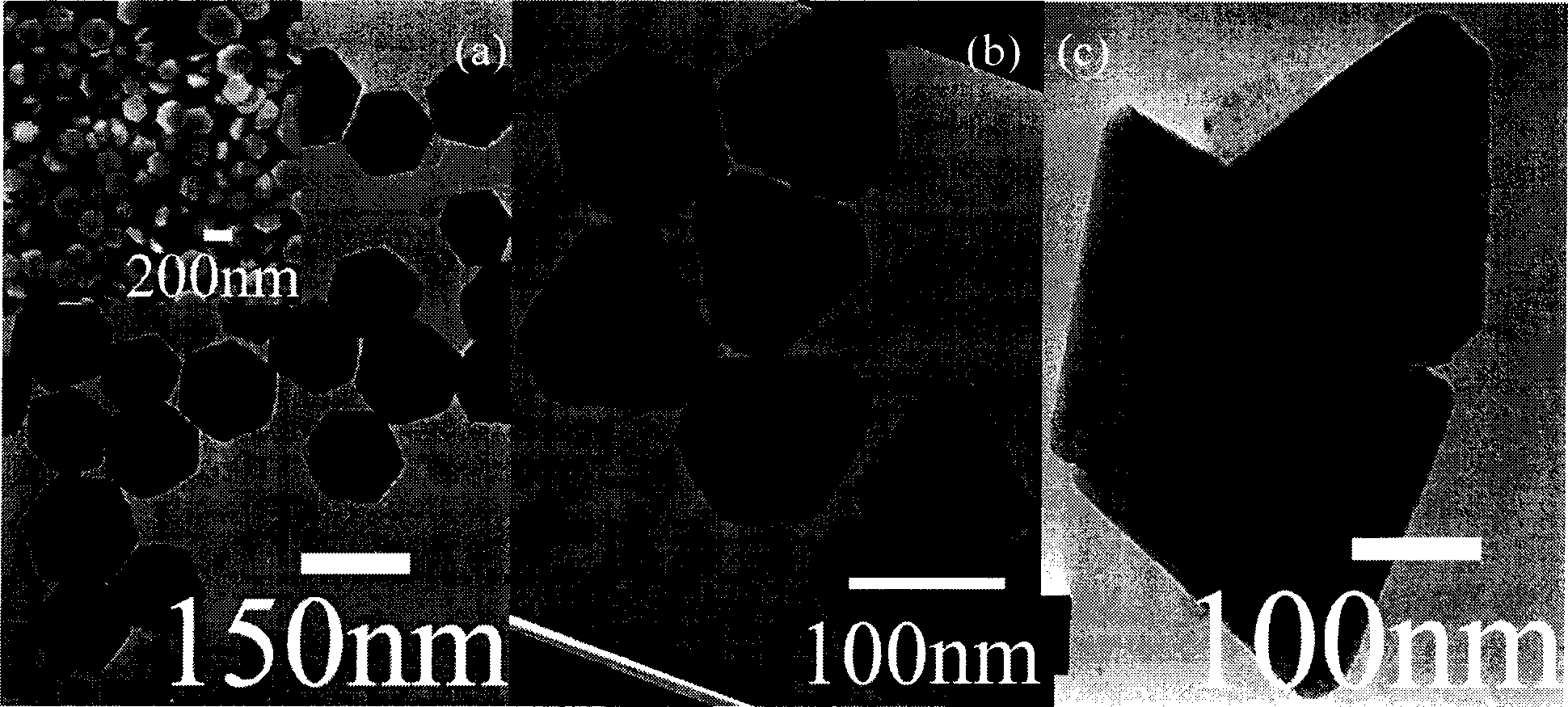

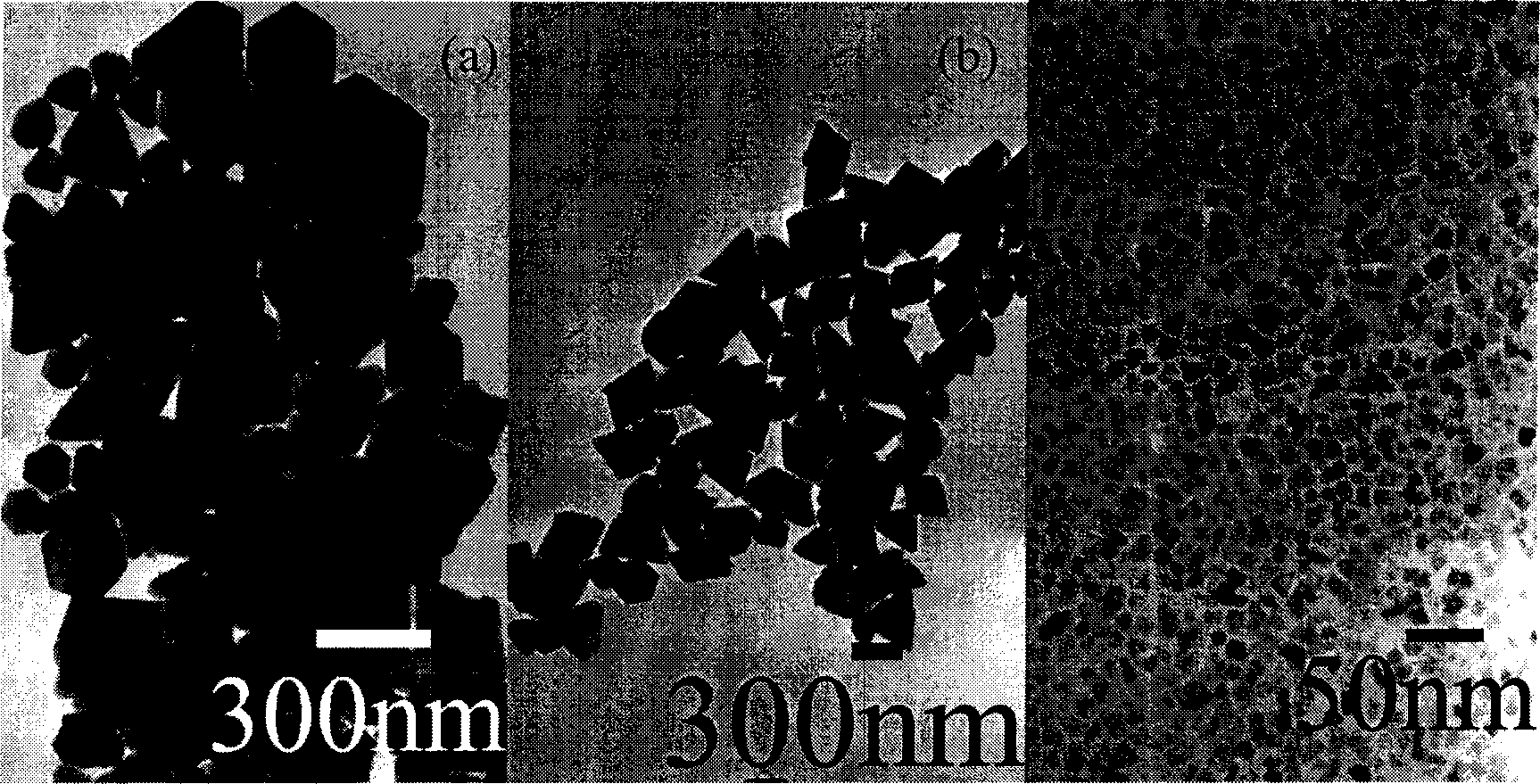

Method for preparing different shaped nano zinc oxide by thermal decomposition

The invention discloses a method to prepare nano ZnO of different shape by thermal decomposition. Wherein, using zinc acetate as predecessor and oleic acid as surfactant, refluxing in tri-n-octylamine of high boiling point to obtain nano ZnO particles of different shape and even size and with surface packaged by oleic acid. According to experiment result, it finds a simple method to prepare nano ZnO particle of hexagon, diamond shape and triangle. This invention is simple and low cost, and has high use value in optical device design and manufacture.

Owner:ZHEJIANG UNIV

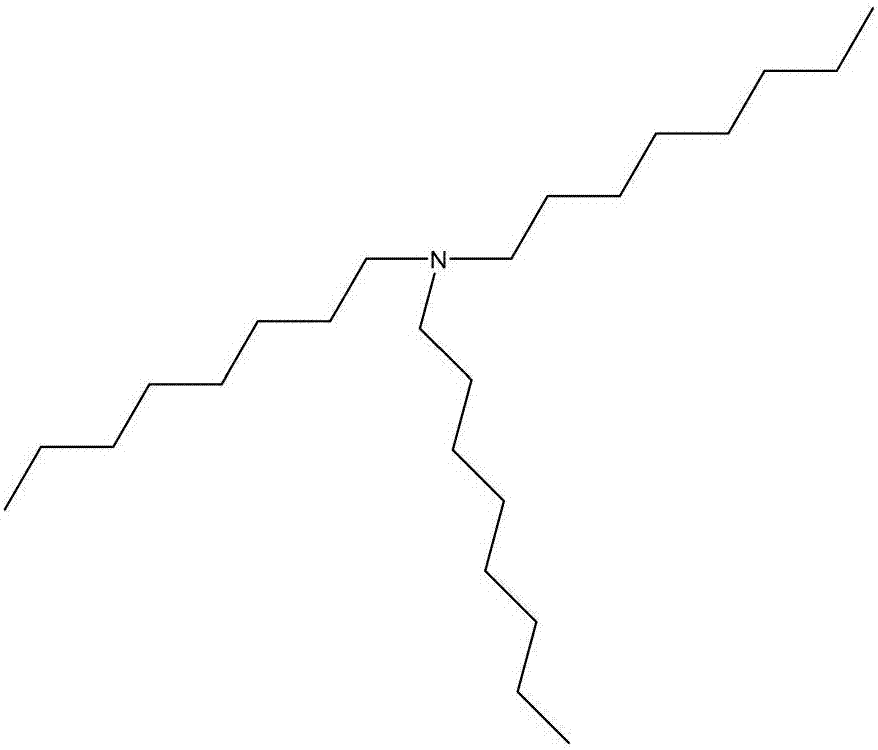

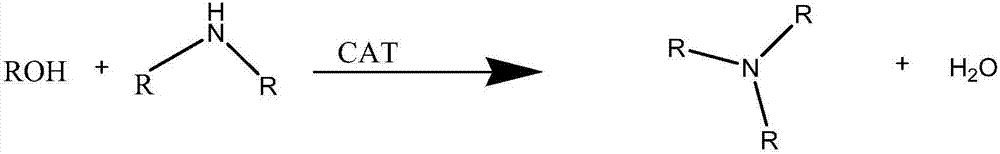

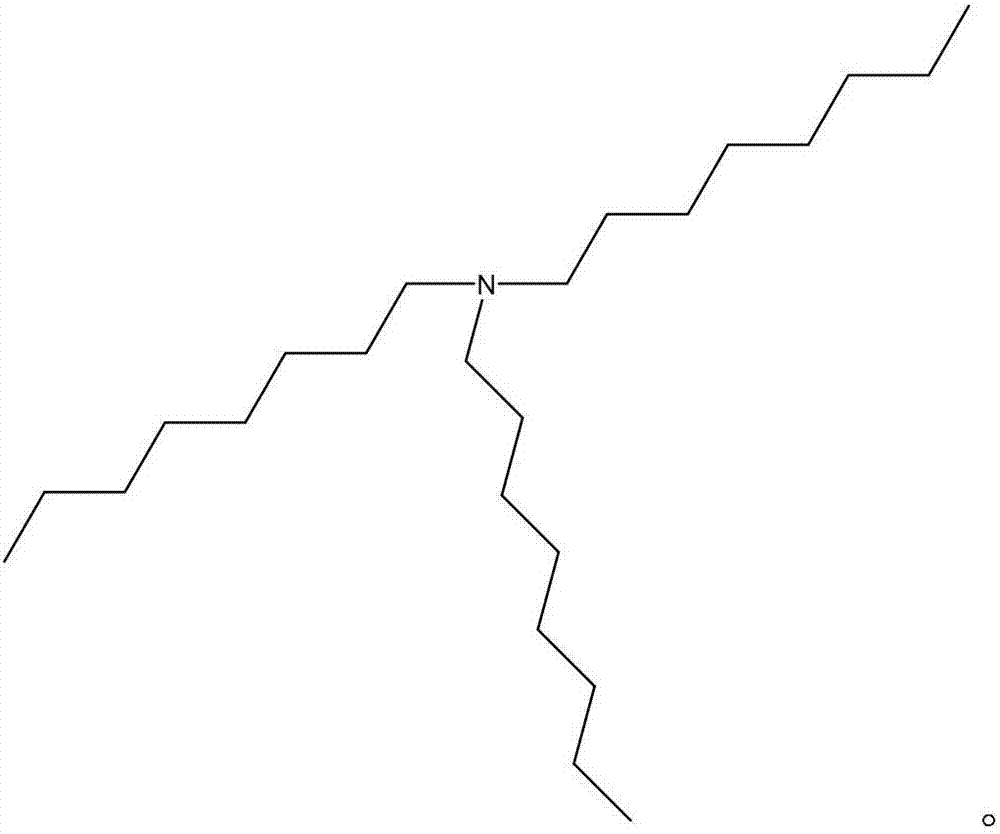

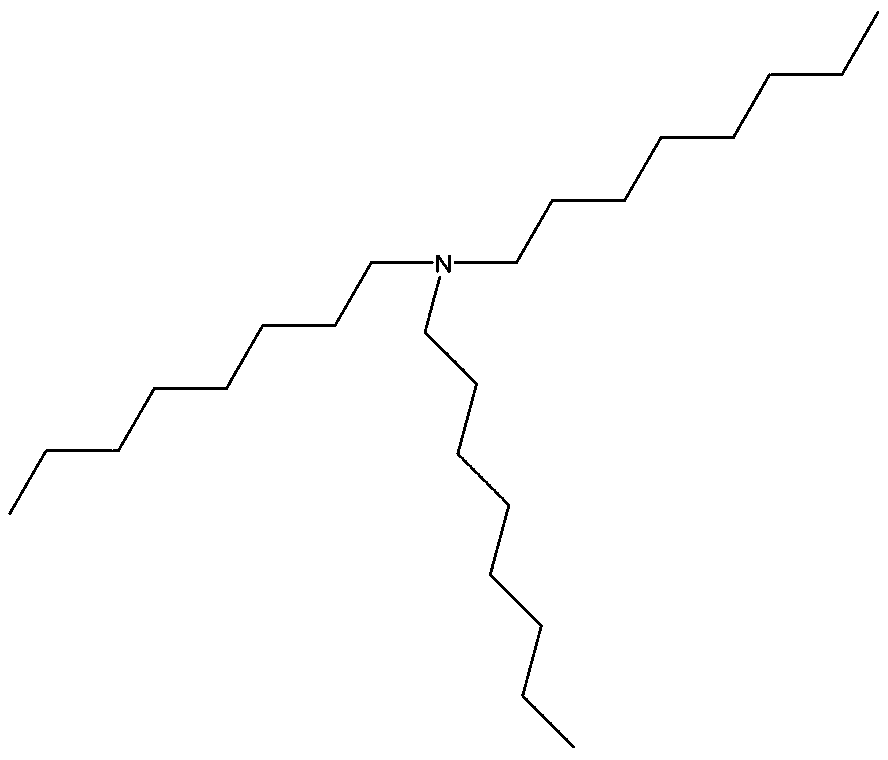

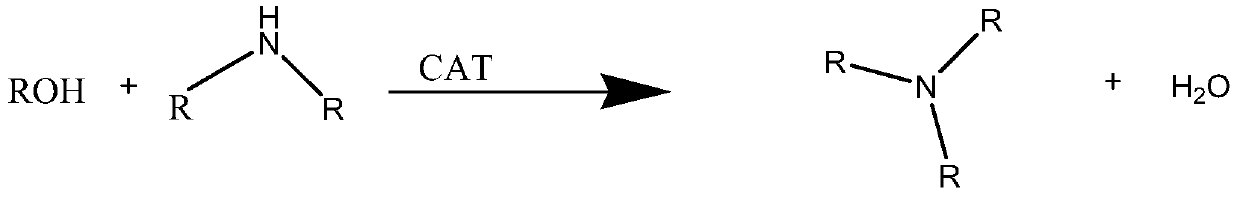

Tri-n-octylamine preparation method

ActiveCN107540557ARealize comprehensive utilizationReduce the discharge of three wastesMetal/metal-oxides/metal-hydroxide catalystsAmino compound preparation by condensation/addition reactionsAlcoholDistillation

The invention discloses a tri-n-octylamine preparation method. The preparation method comprises the following preparation steps: throwing di-n-octylamine, n-caprylic alcohol and an alkaline earth metal oxide catalyst into a reactor; keeping hydrogen atmosphere after nitrogen displacement and hydrogen displacement are performed, reducing the catalyst for 1+ / -0.5 hour at 160 to 190 DEG C; heating and reacting, sampling and performing GC detection when the collected generated water amount reaches 95 percent or above a theoretical amount and the change amount in half an hour does not exceed 2 weight percent, and ending the reaction to obtain crude tri-n-octylamine when the content of the di-n-octylamine is less than or equal to 2 weight percent; cooling, precipitating the crude tri-n-octylamine, and finally, rectifying to obtain the tri-n-octylamine. According to the process route, the initial raw materials come from distillation residues of the tri-n-octylamine; a byproduct of the companyis changed from waste into treasure, so that waste utilization is realized; the emission of waste water, waste gas and solid waste is reduced; the environmental protection is benefited; the economicbenefit is increased.

Owner:江苏万盛大伟化学有限公司

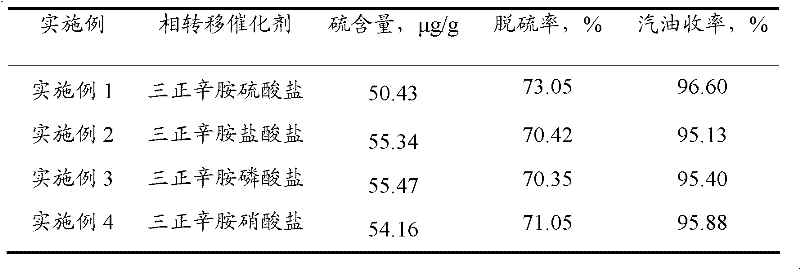

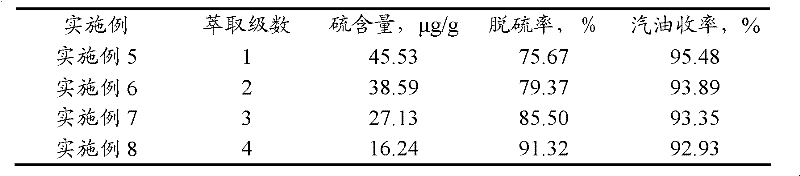

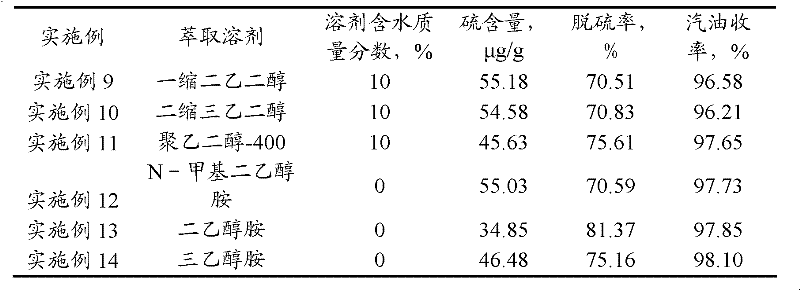

Phase-transfer catalytic oxidation extraction desulphurization method for gasoline

InactiveCN102311780AHigh desulfurization rateHigh gasoline yieldTreatment with plural serial refining stagesCatalytic oxidationGasoline

The invention provides a phase-transfer catalytic oxidation extraction desulphurization method for gasoline. The method comprises the following steps: adding an oxidation catalyst and a phase-transfer catalyst, an inorganic acid salt of tri-n-octylamine, into an oxidizing agent of hydrogen peroxide to prepare an oxidizing solution; carrying out oxidation treatment on gasoline with the oxidizing solution under mild conditions, and rinsing the gasoline so as to obtain oxidized gasoline; extracting the oxidized gasoline with an extracting solvent, and rinsing the gasoline again so as to realize desulphurization of the gasoline. The invention has the characteristics of a simple and practicable process, a high gasoline desulfurization rate, high yield of gasoline, etc., and has a good application prospect.

Owner:ZHEJIANG UNIV OF TECH

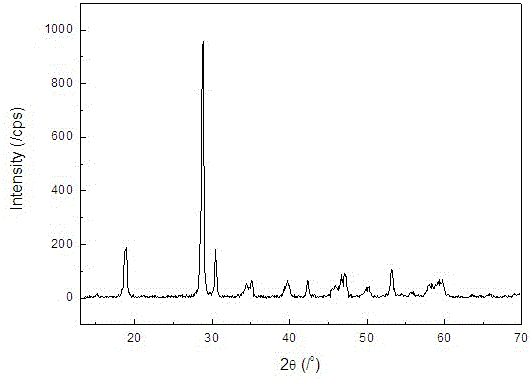

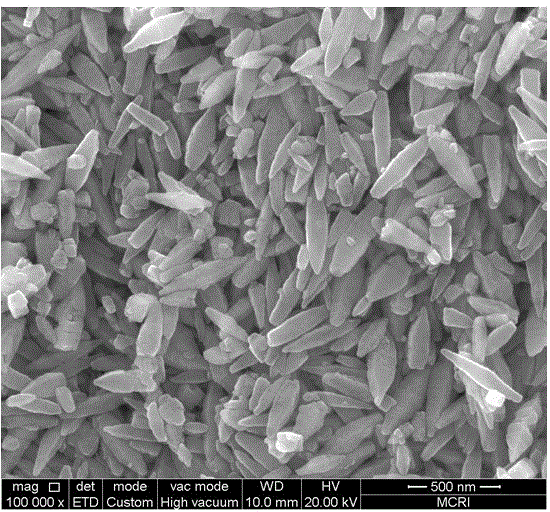

Preparation method of monoclinic phase ditetrahedron bismuth vanadate crystal

The invention relates to a preparation method of a monoclinic phase ditetrahedron bismuth vanadate crystal. The method comprises steps of: dissolving Bi (NO3) 3.5H2O in a HNO3 solution, adding 1.3-1.4g of NaOH to obtain a mixed solution A, mixing a certain amount of n-caprylic acid and toluene to obtain a mixed solution B, mixing the solution A and the solution B, stirring, standing, and taking an upper layer solution C; dissolving NaVO3 in HNO3 solution with a certain pH value to obtain a solution D, mixing a certain amount of tri-n-octylamine and toluene to obtain a mixed solution E, mixing the solution D with the solution E, stirring, standing, and taking an upper layer solution F; then mixing the solution C and the solution F, adding 2-4 mL of oil amine, stirring evenly to obtain a solution G, adding the solution G in a teflon container, reacting for 16-20 h at high temperature, cooling, centrifuging and cleaning to obtain a sample; and finally, drying the sample in a vacuum drying box to obtain the monoclinic phase ditetrahedron bismuth vanadate crystal. The method provided by the invention can prepare monoclinic phase ditetrahedron bismuth vanadate crystal with good dispersion, uniform morphology and small particle size, and has a simple preparation process and a short cycle.

Owner:XIDIAN UNIV

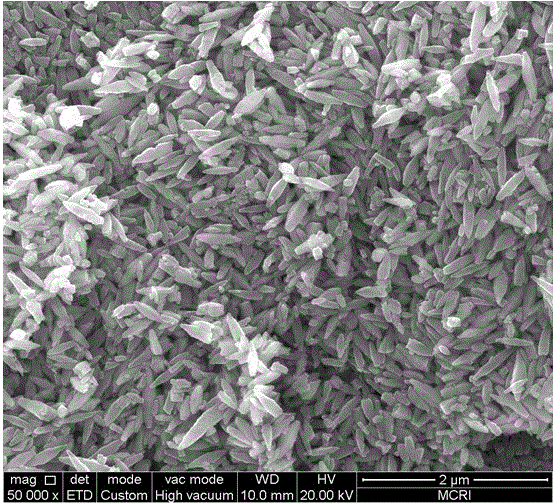

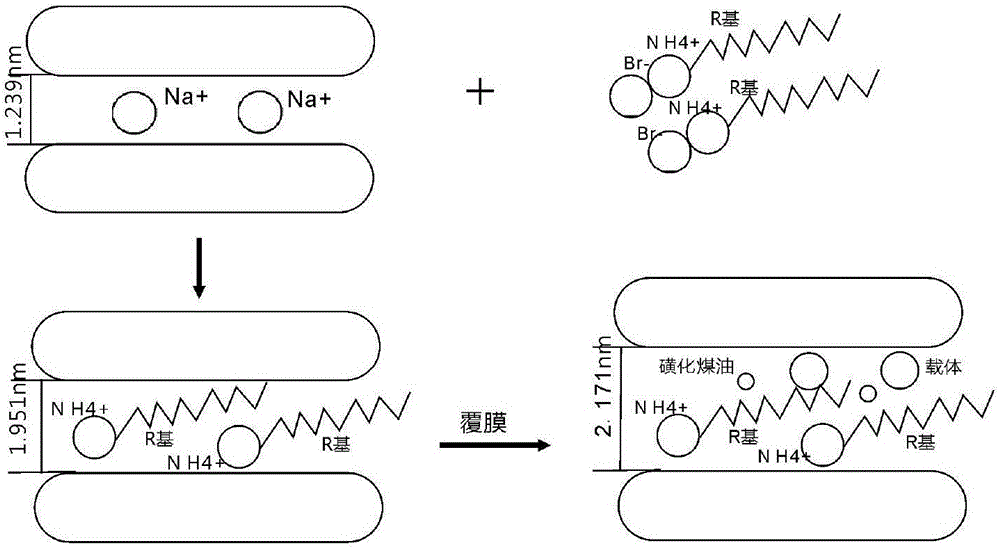

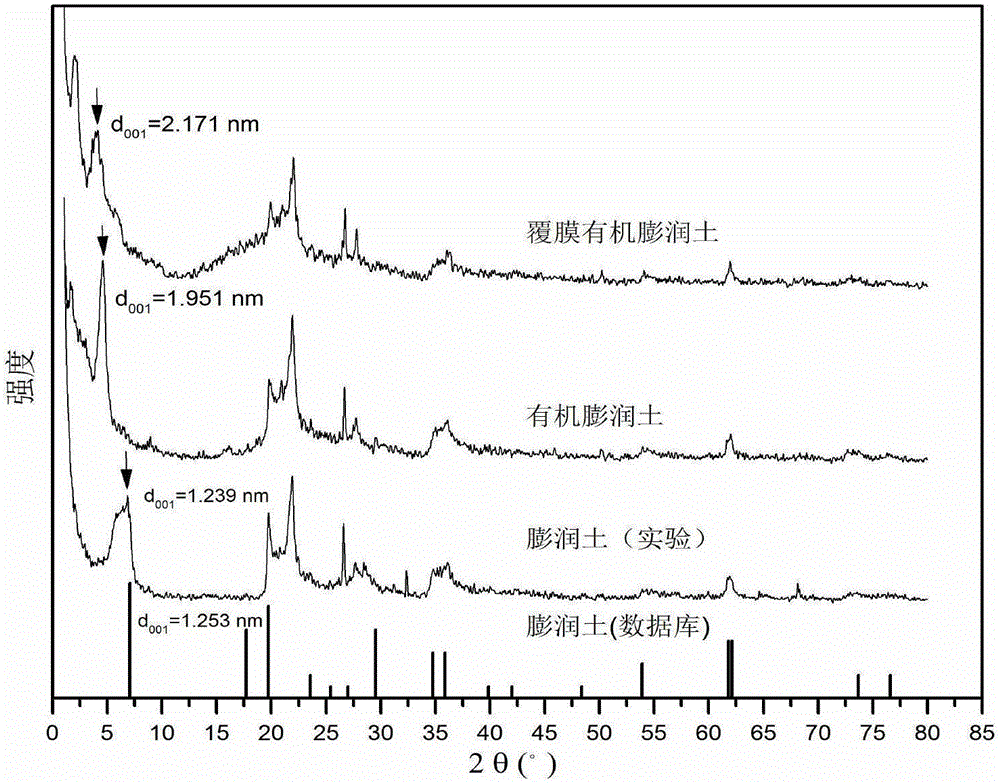

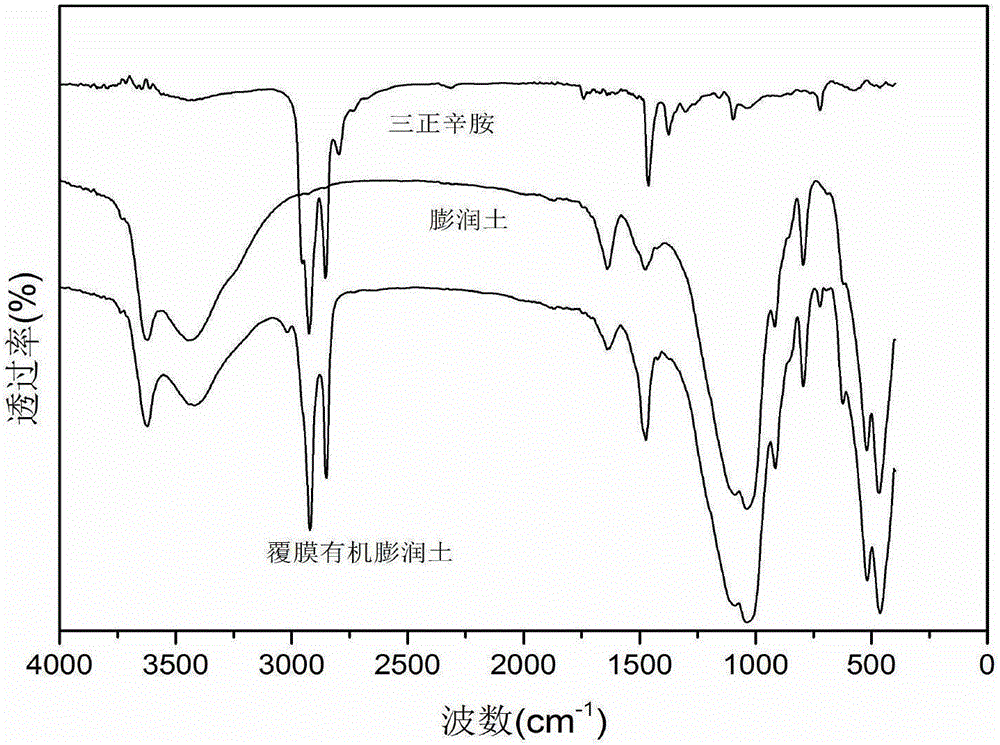

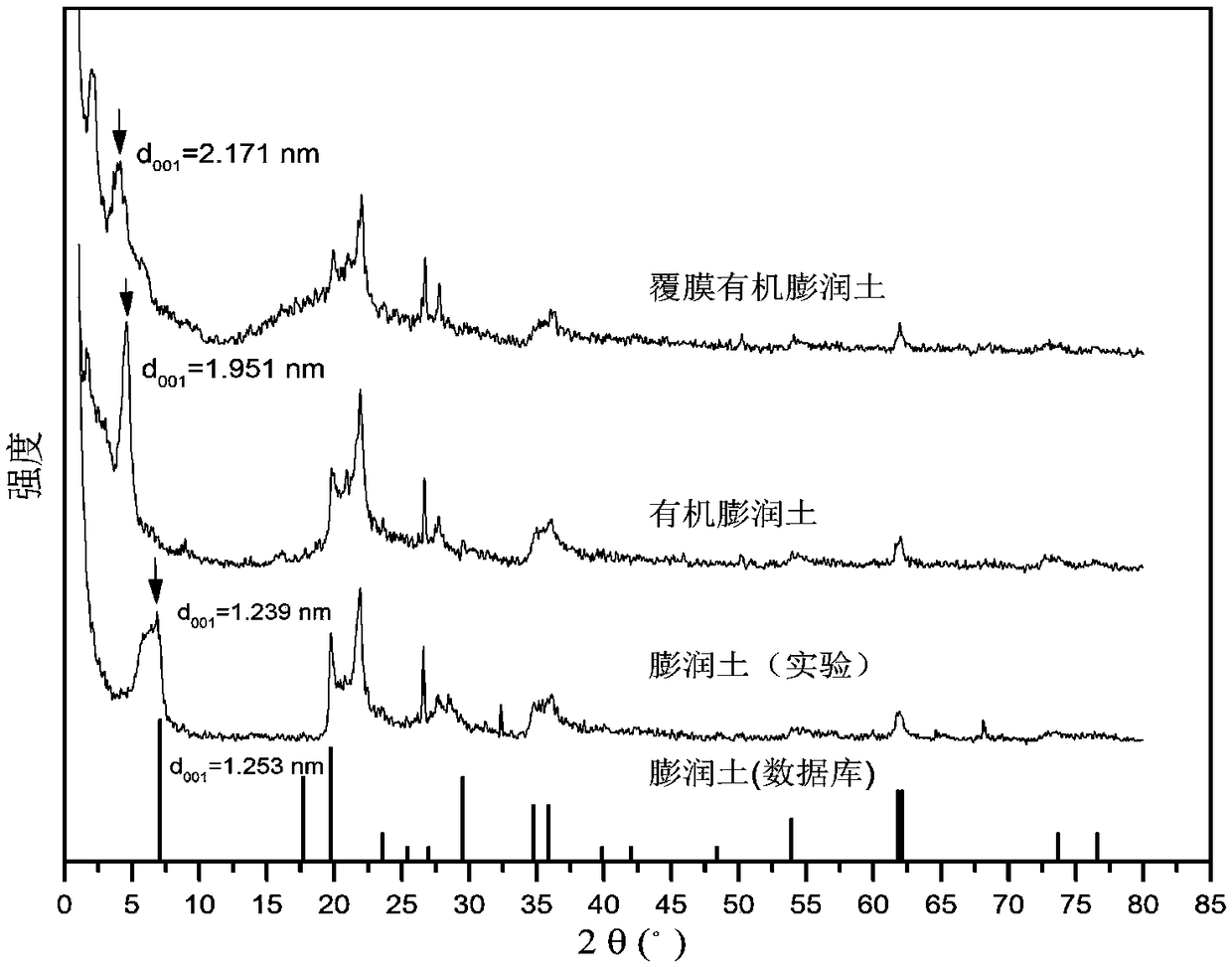

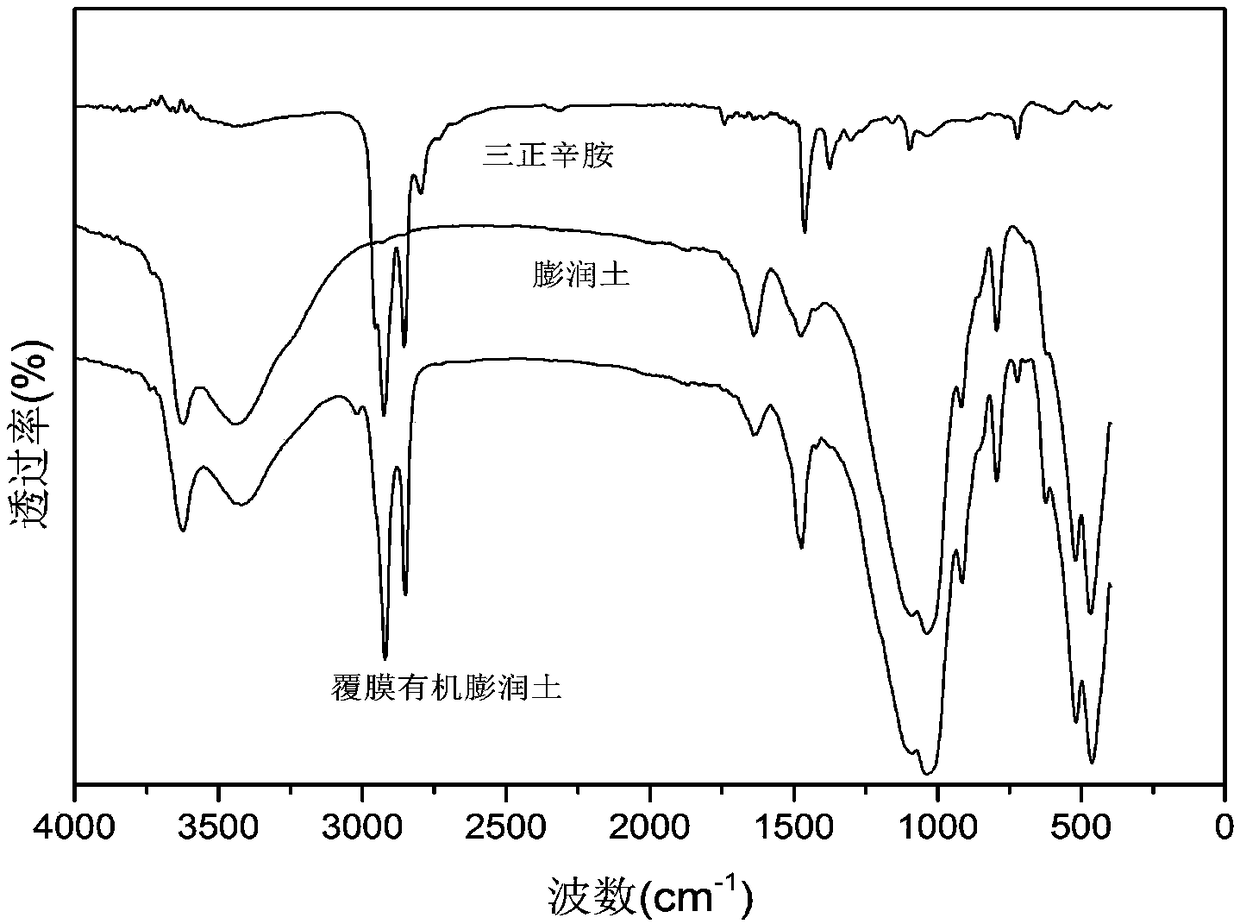

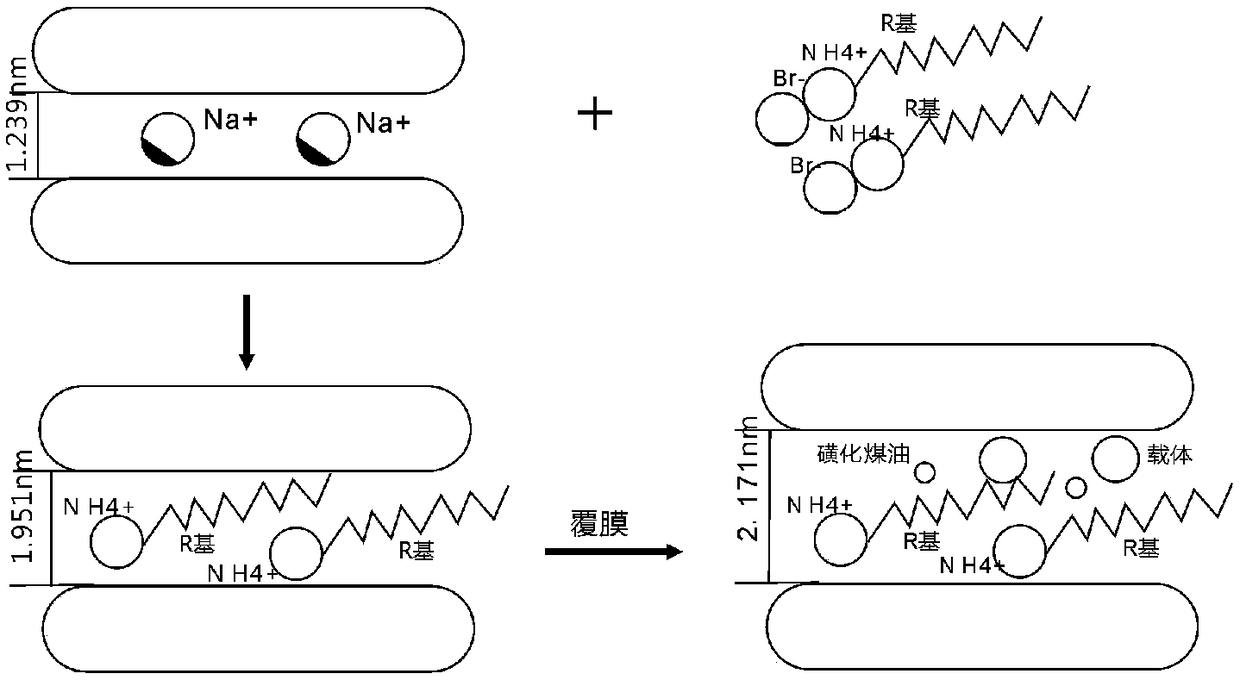

Preparation method and application of coated organic bentonite

InactiveCN106076265AImprove production efficiencyLow costOther chemical processesWater contaminantsWater bathsSodium Bentonite

The invention discloses a preparation method and application of coated organic bentonite , and belongs to the technical field of preparation of organic bentonite. The technical problem that the adsorption rate of the organic bentonite is low in the prior art is solved. The preparation method comprises the following steps: first, evenly mixing cetyl trimethylammonium bromide, anhydrous ethanol and deionized water to obtain a mixed liquid A, evenly mixing the sodium bentonite and the obtained mixed liquid A and then vibrating in a water bath, cooling to room temperature and then centrifuging, washing, drying and sieving to obtain organic modified bentonite; then vibrating tri-n-octylamine and sulphonated kerosene at room temperature in a water bath to obtain a coated liquid B; finally, after fully adsorbing the organic modified bentonite and the coated liquid B, and subjecting to ultrasound and aging and other steps, obtaining coated organic bentonite. The coated organic bentonite prepared by the invention can be used for treating cadmium-containing wastewater, and has high adsorption capacity and large adsorption capacity.

Owner:SHANDONG UNIV OF SCI & TECH

Method for separating and recovering gold or silver by inner-coupling liquid membrane

InactiveCN101550486AAchieving high-volume recyclingSimple and fast operationProcess efficiency improvementKeroseneCoupling

The invention discloses a method for separating and recovering gold or silver by an inner-coupling liquid membrane. The method is implemented according to the following steps: feed liquor, liquid membrane phase and strip liquor are prepared; KCl and HCl are added in the feed liquor in which the gold needs to be recovered, thus ensuring that the concentration of H in the feed liquor phase is 2 to 3 mol / L; while KSCN and HNO3 are added in the feed liquor in which the silver needs to be recovered, thus ensuring that the concentration of H in the feed liquor phase is 0.1 to 1 mol / L; the concentration of KCl or KSCN is 2 to 3 mol / L; the liquid membrane phase is prepared by mixing tri-n-octylamine, tributyl phosphate and kerosene; the strip liquor, from which gold is recovered, by mixing KCN with the concentration of 0.10 to 0.50 mol / L and KCl with the concentration of 1 to 2 mol / L, and preparing the stripping solution, from which silver is recovered, by mixing Na2S2O3 with the concentration of 0.10 to 0.50 mol / L and KNO3 with the concentration of 1 to 2 mol / L; extracting; and stripping. By using the method for separating and recovering gold or silver by the inner-coupling liquid membrane, the recovery rate of gold or silver can reach more than 85 percent, and migration of copper, zinc, cadmium and lead is less than 5 percent, thus realizing separation and recovery of gold or silver from copper, zinc, cadmium and lead.

Owner:NANTONG YAWEI MACHINERY MFG

Efficient purifying method of triethyl gallium

ActiveCN104817579AEasy to operateImprove the purification effectComponent separationSolid sorbent liquid separationStationary phaseChromatographic column

The invention relates to an efficient purifying method of triethyl gallium, belonging to the technical field of compound purification. The purifying method comprises the following steps of firstly, filtering a crude product of triethyl gallium by using a first chromatographic column with a stationary phase as filler; and then, purifying the filtered crude product of triethyl gallium in a second chromatographic column with a stationary phase as surface grafted filler, wherein the surface grafted filler is filler of which the surface is grafted with tri-n-octylamine. The purifying method disclosed by the invention is combined with a solid-liquid separation means, and a specific coordination agent is loaded on the filler, so that not only is the method simple, but also the purifying effect is further improved.

Owner:苏州普耀光电材料有限公司

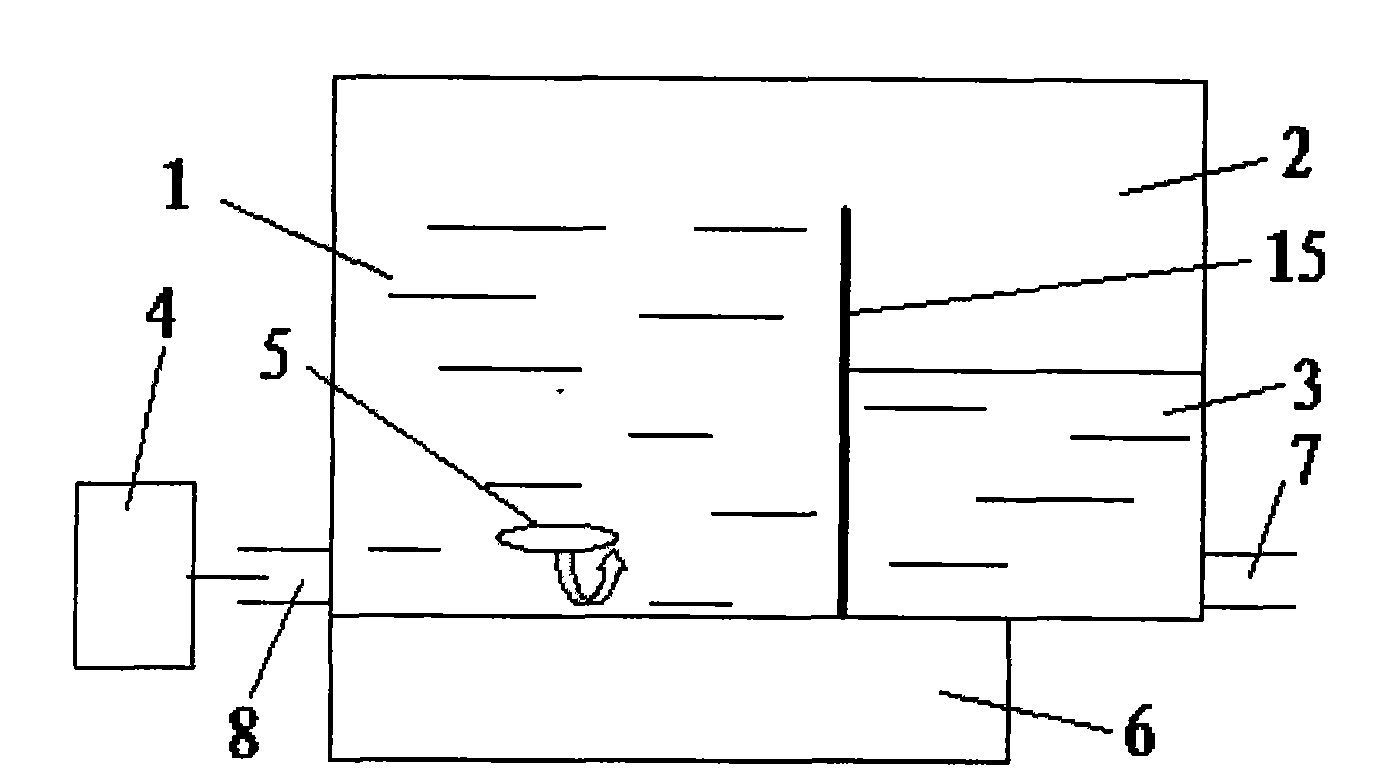

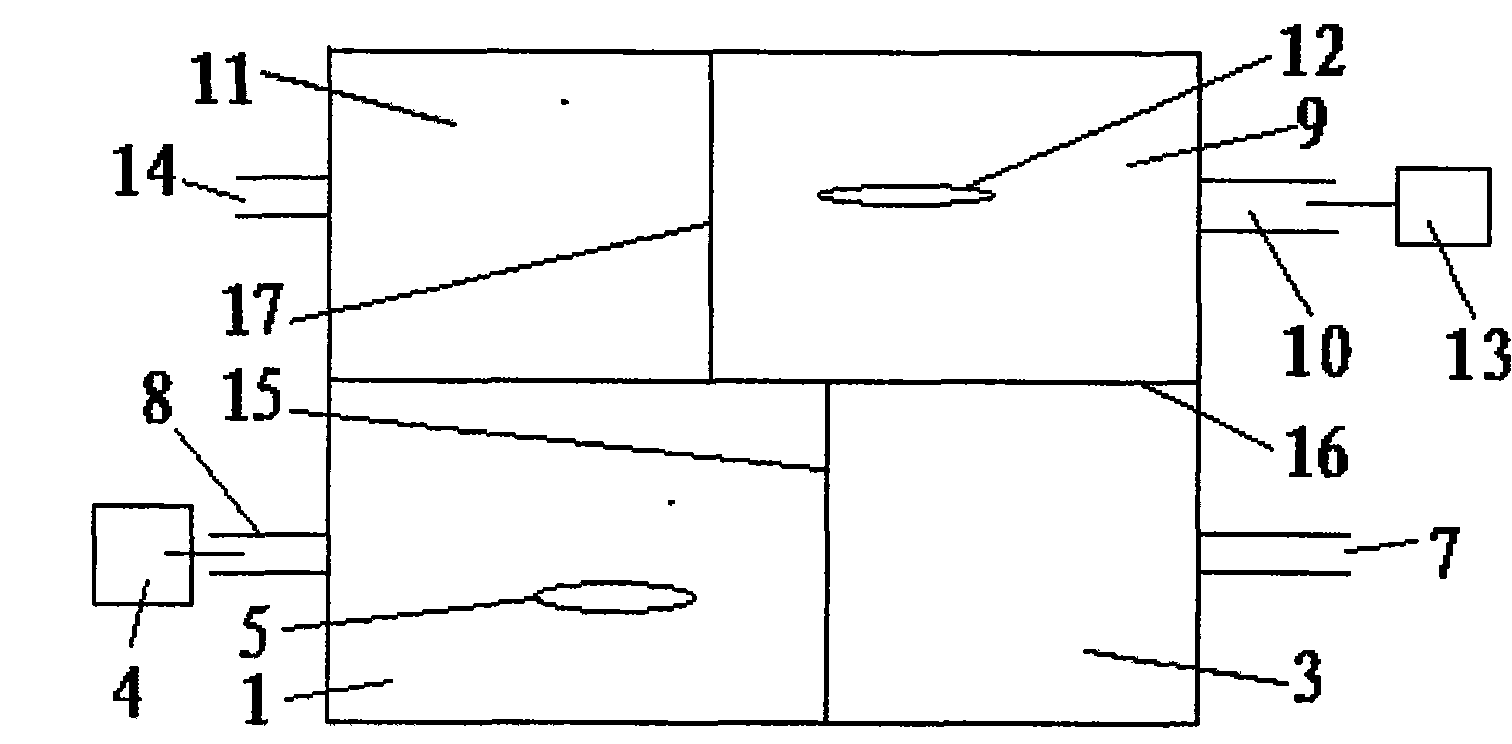

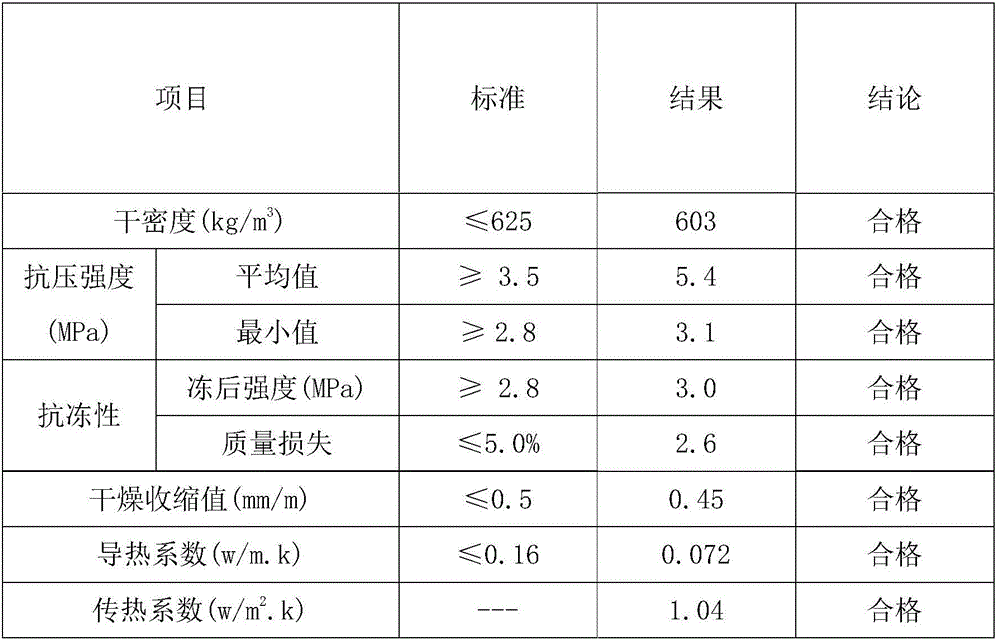

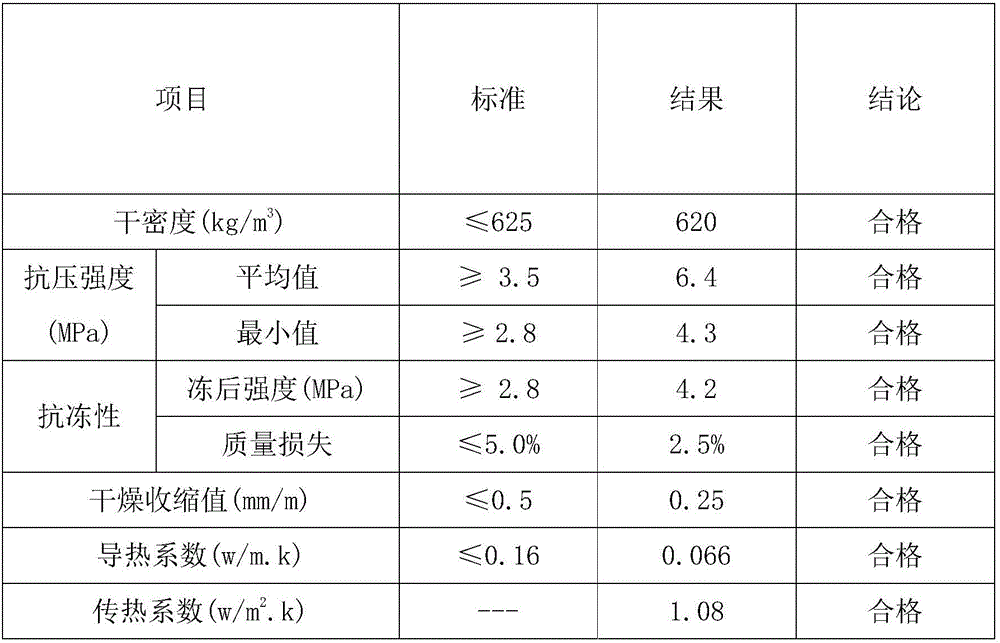

High-strength coal ash waste glass aerated concrete block and processing method thereof

InactiveCN106187312AReduce pollutionImprove liquiditySolid waste managementCeramicwareSodium stearateTriterpenoid saponin

The invention discloses a high-strength coal ash waste glass aerated concrete block and a processing method thereof. The high-strength coal ash waste glass aerated concrete block is prepared from, by weight, 20-30 parts of coal ash, 30-40 parts of waste glass, 2-4 parts of gypsum, 3-5 parts of quick lime, 2-4 parts of kaolin, 2-4 parts of zeolite, 4-6 parts of cement, 1-2 parts of hydroxypropyl methyl cellulose, 1-2 parts of shell activated carbon, a proper amount of water, 0.2-0.4 part of tri-n-octylamine, 1-2 parts of additives, 1-2 parts of aluminum powder, 0.2-0.4 part of oxidized starch, 0.01-0.02 part of polyoxyethylene alcohol ether, 0.2-0.3 part of triterpenoid saponins, 0.01-0.03 part of sodium stearate, and 0.02-0.04 part of benzotriazole. The high-strength coal ash waste glass aerated concrete block is small in drying shrinkage value, good in anti-cracking ability and water resistance, various performances can meet the national standard, and compared with existing products, the strength of the high-strength coal ash waste glass aerated concrete block is obviously improved.

Owner:安徽阜阳富龙建筑材料有限责任公司

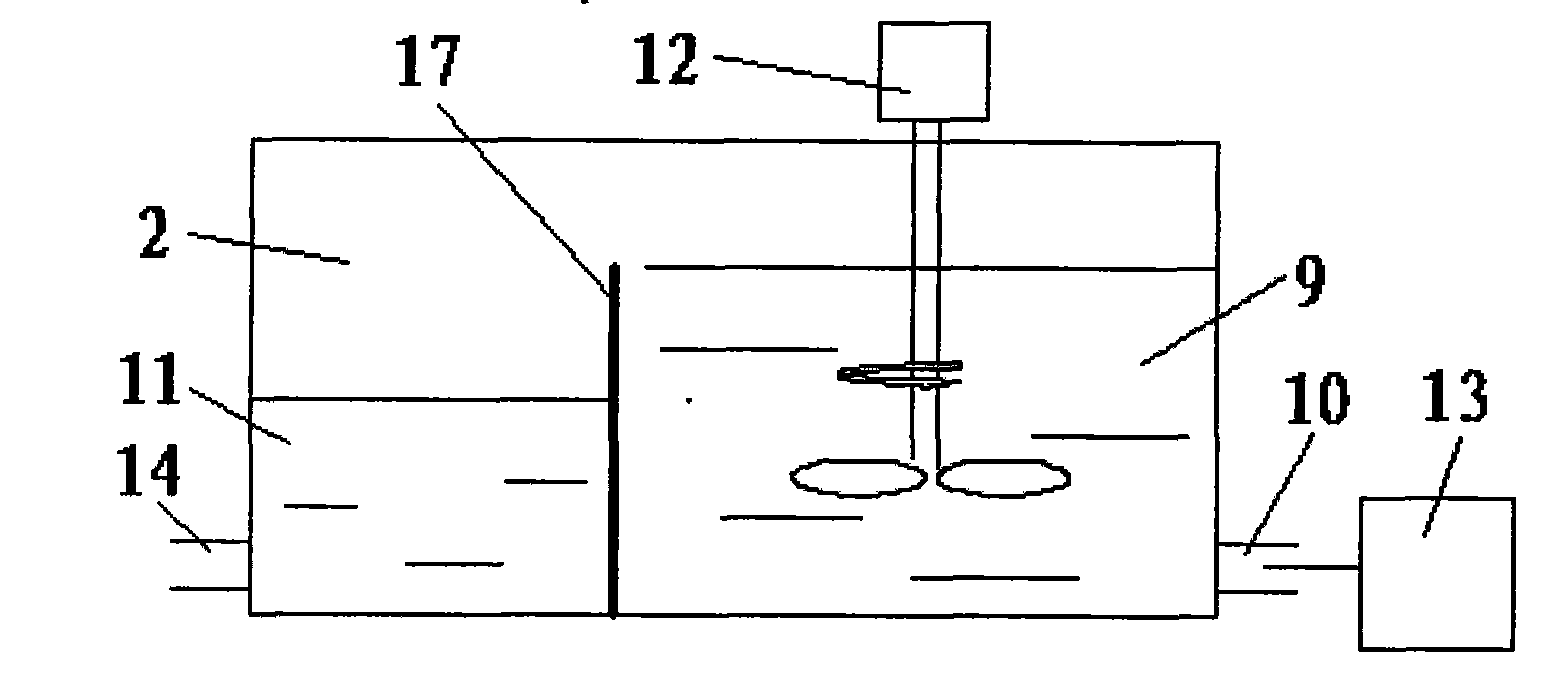

High-strength flyash and quartz sand aerated concrete block and processing method thereof

InactiveCN106242402AReduce pollutionImprove liquidityMixing operation control apparatusCeramic shaping apparatusSodium stearateCrack resistance

The invention discloses a high-strength flyash and quartz sand aerated concrete block and a processing method thereof. The high-strength flyash and quartz sand aerated concrete block is composed of the following raw materials (by weight): 35-45 parts of flyash, 10-12 parts of quartz sand, 8-10 parts of stone flour, 4-6 parts of steel slag, 5-7 parts of red mud, 1-2 parts of attapulgite, 2-4 parts of waste plastic, 1-2 parts of calcium of molasses, 6-8 parts of cement, a proper amount of water, 0.2-0.4 part of tri-n-octylamine, 1-2 parts of an additive, 1-2 parts of aluminium powder, 0.2-0.4 part of flour, 0.01-0.02 part of polyoxyethylene aliphatic alcohol ether, 0.2-0.3 part of triterpenoidal saponin, 0.01-0.03 part of sodium stearate and 0.02-0.04 part of benzotriazole. The aerated concrete block has small drying shrinkage value, good crack resistance and good water resistance. Various properties of the aerated concrete block meet national standard. In comparison with strength of existing products, strength of the aerated concrete block of the invention is obviously raised.

Owner:安徽阜阳富龙建筑材料有限责任公司

Refined monochloroacetic acid crystalline product complexometric extraction method

InactiveCN102731287AReduce energy consumptionHigh separation selectivityCarboxylic compound separation/purificationAliphatic amineChloroacetic acid

The invention discloses a refined monochloroacetic acid crystalline product complexometric extraction method. The method comprises: first using the normal hexane solution of aliphatic amine to carry out complexometric extraction to obtain the water solution of the monochloroacetic acid crystalline product (quality purity about 99.0%), standing for layering with the upper phase being an organic phase and the lower phase being a water phase, then using the normal hexane to extract the water phase, and vaporizing the water phase to obtain a solid which is the refined monochloroacetic acid (quality purity above 99.9%). The key in the technology is the employed aliphatic amine is a mixture of tri-n-octylamine and di-n-octylamine. As a complexometric extraction agent, the mixture can effectively remove the main impurity of dichloroacetic acid in the monochloroacetic acid crystalline product.

Owner:ZHEJIANG UNIV

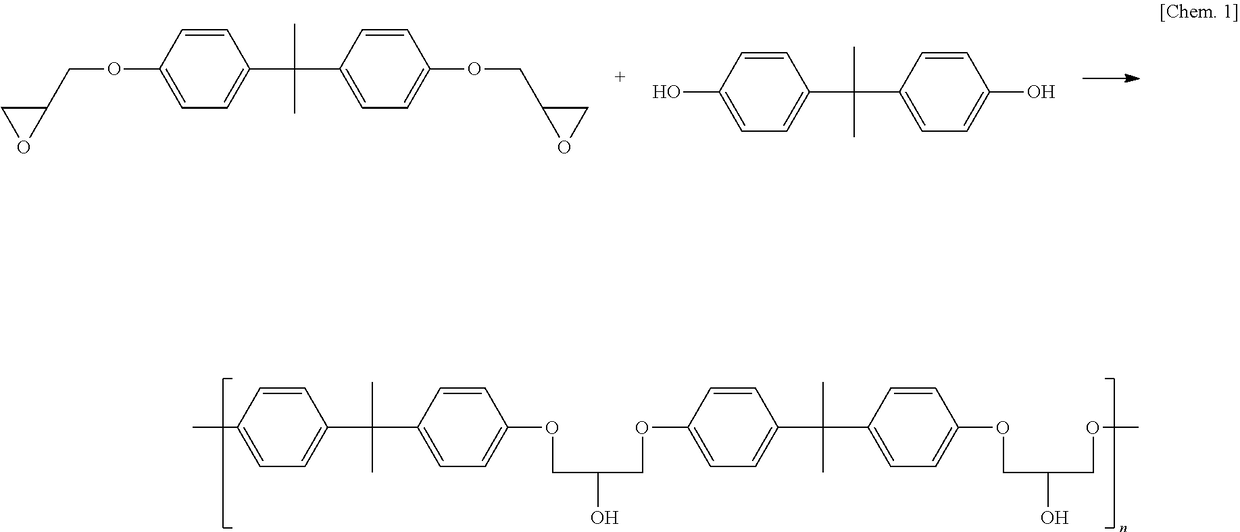

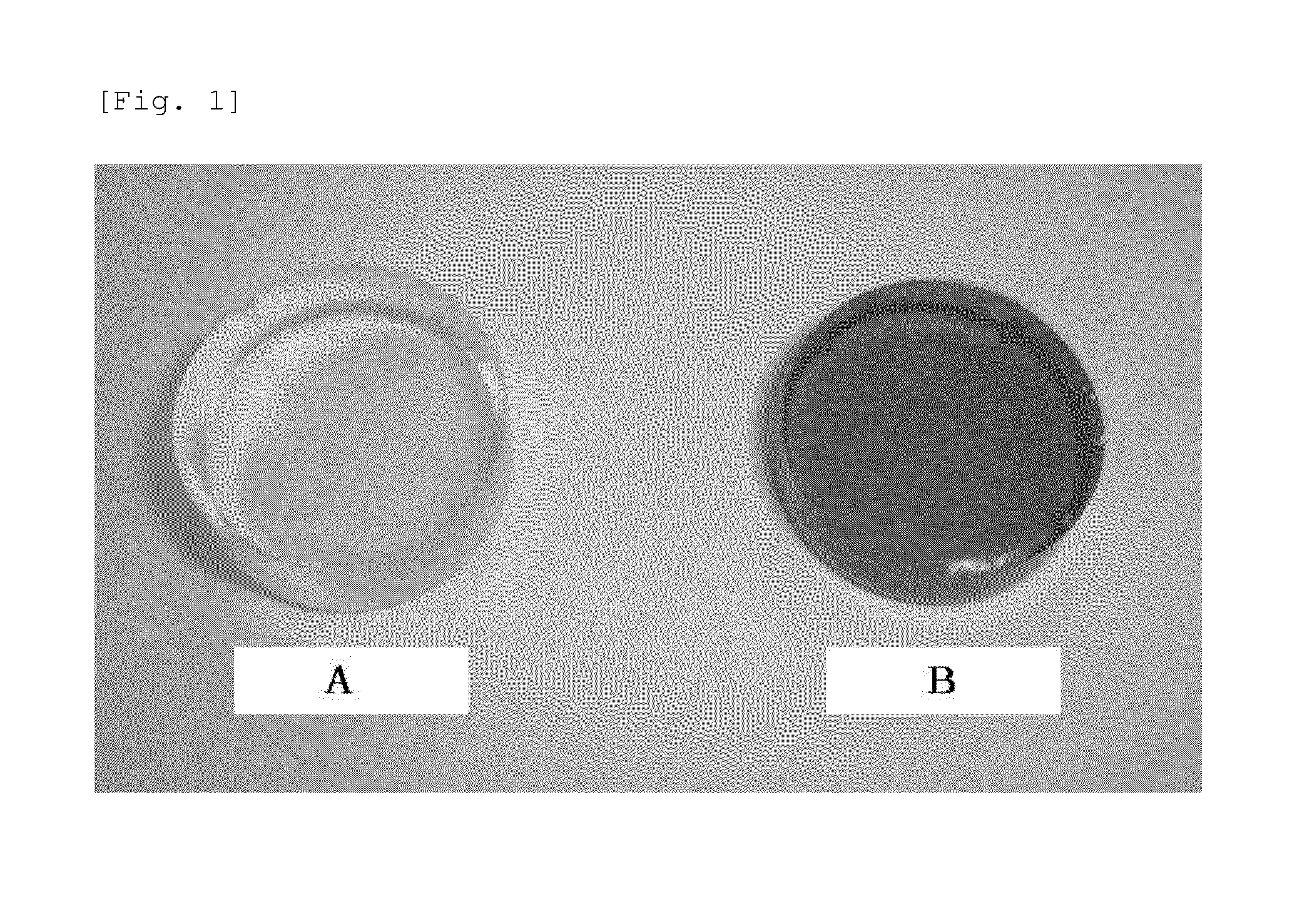

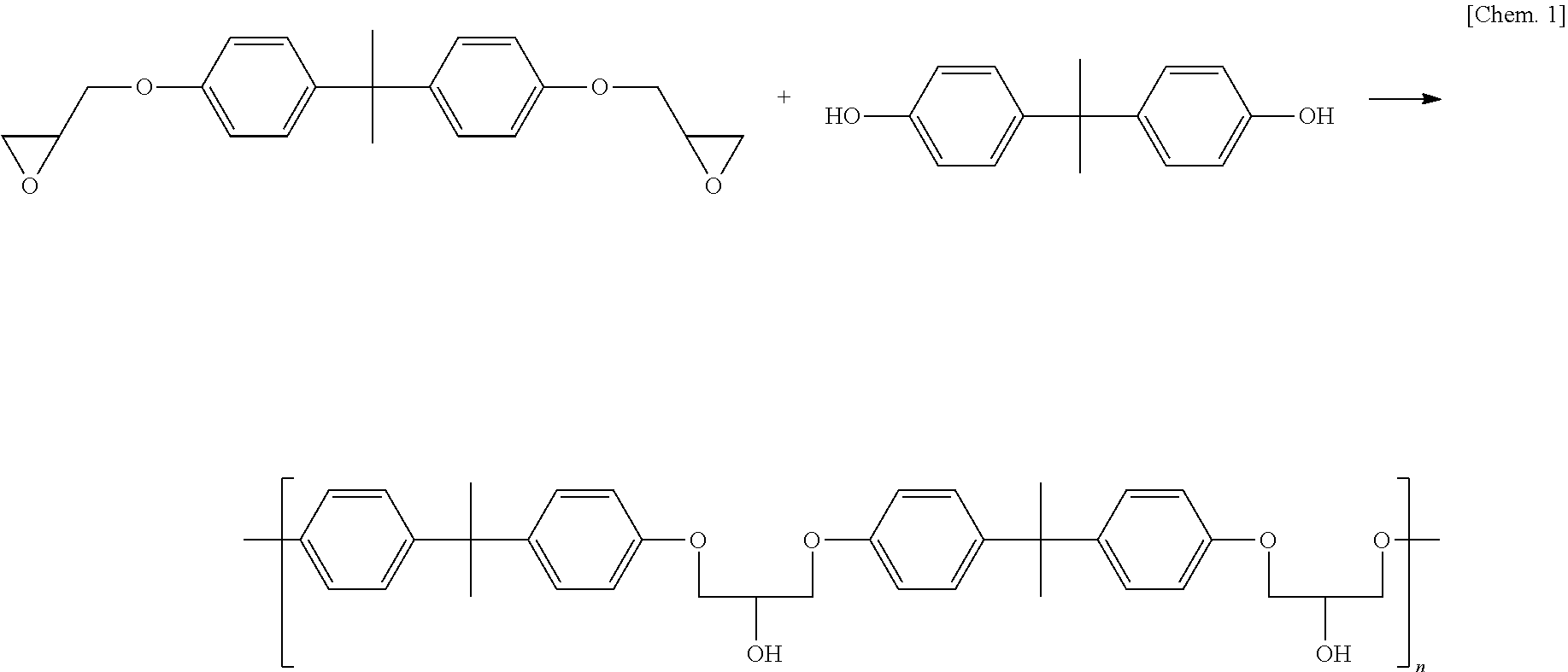

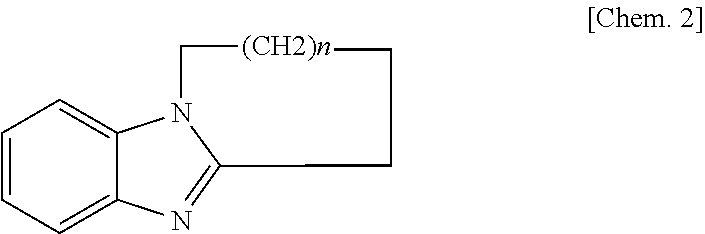

Process for production of thermoplastic cured epoxy resin with transparency to visible light, and thermoplastic epoxy resin composition

Provided are a thermoplastic epoxy resin composition comprising (A) an epoxy compound having two epoxy groups in one molecule, (B) a compound having two phenolic hydroxyl groups in one molecule, and at least one compound selected from the group consisting of dihexylamine, diheptylamine, di(2-ethylhexyl)amine, N-ethylhexylamine, trihexylamine, dioctylamine, tri n-octylamine, N,N-dimethyl-n-octylamine, and N,N-dimethyldecylamine as (C) a curing accelerator, and a thermoplastic cured epoxy resin with transparency to visible light produced by curing the thermoplastic epoxy resin composition.

Owner:NAGASE CHEMTEX CORPORATION

Method for extracting paracumyl phenol from phenol tar

ActiveCN107298636ASolve the current situation of low purityReduce loss rateOrganic chemistryOrganic compound preparationMass ratioDistillation

The invention provides a method for extracting paracumyl phenol from phenol tar. The method comprises the following steps: (1) the phenol tar is subjected to reduced pressure distillation to obtain key components, wherein the key components are the paracumyl phenol, acetophenone, an alpha-methylstyrene bipolymer and phenol; and (2) solvents are added dropwise to the key components, wherein the dropping speed is controlled in the range from 55 drops / minute to 65 drops / minute, then the temperature is slowly raised from room temperature to 313K-323K, and stirring is slowly conducted at a constant speed in the temperature-raising process, wherein the solvents are composed of tri-n-octylamine and octylamine, and the mass ratio of the tri-n-octylamine to the octylamine is (80-85):(20-15). The method solves the current situation that the purity of paracumyl phenol extracted from the phenol tar is not high by using an extractant provided in the invention, and meanwhile, the mixture of the trioctylamine and the octylamine as the extractant has the advantages of low loss ratio and easy recovery.

Owner:PETROCHINA CO LTD

Purification method for removing diethyl ether from trimethyl antimony

ActiveCN113831367AEfficient removalImprove reaction efficiencyAntimony organic compoundsProcess efficiency improvementEthyl groupDiethyl ether

The invention provides a purification method for removing diethyl ether from trimethyl antimony, the method comprises the following steps: using one of trimethylaluminum, trimethyl indium and triethyl gallium as an additive I, forming a high-boiling-point complex with diethyl ether, distilling and collecting the trimethyl antimony and a small amount of the additive I, then adding one of high-boiling-point tri-n-octylamine, tri-n-butylamine, MBDA and crown ether as an additive II to coordinate with the additive I to form a high-boiling-point coordination compound, and finally rectifying and purifying to obtain the 6N trimethyl antimony product. The method is low in cost, high in reaction efficiency and high in safety performance, diethyl ether can be effectively removed, harsh reaction conditions are not needed, and the operation is simple.

Owner:安徽亚格盛电子新材料有限公司

Process for production of thermoplastic cured epoxy resin with transparency to visible light, and thermoplastic epoxy resin composition

Provided are a thermoplastic epoxy resin composition comprising (A) an epoxy compound having two epoxy groups in one molecule, (B) a compound having two phenolic hydroxyl groups in one molecule, and at least one compound selected from the group consisting of dihexylamine, diheptylamine, di(2-ethylhexyl)amine, N-ethylhexylamine, trihexylamine, dioctylamine, tri n-octylamine, N,N-dimethyl-n-octylamine, and N,N-dimethyldecylamine as (C) a curing accelerator, and a thermoplastic cured epoxy resin with transparency to visible light produced by curing the thermoplastic epoxy resin composition.

Owner:NAGASE CHEMTEX CORPORATION

Preparation method of high-purity trimethylindium

ActiveCN104860972BEasy to operateImprove the purification effectGroup 3/13 element organic compoundsStationary phaseCombinatorial chemistry

The invention relates to a preparation method of high-purity trimethyl indium, belonging to the technical field of preparing group III metallic compounds in the periodic table of elements. The preparation method disclosed by the invention comprises the following steps: (1) taking diethyl ether as a solvent to prepare a trimethyl indium crude product; (2) carrying out purification to the trimethyl indium crude product obtained in step (1), wherein the purification method comprises the step of adopting a first chromatographic column to carry out purification to the trimethyl indium crude product; and the stationary phase adopted by the first chromatographic column is grafted silica, and the grafted silica is silica of which the surface is grafted with tri-n-octylamine. The preparation method disclosed by the invention adopts the two steps of synthesis and separation and obtains the trimethyl indium of which the purity can reach 6N; above all, the purity method adopted is combined with the solid-liquid separation means, a certain coordination agent is loaded on the silica, not only is the operation simple, but also the purification effect is improved further.

Owner:苏州普耀光电材料有限公司

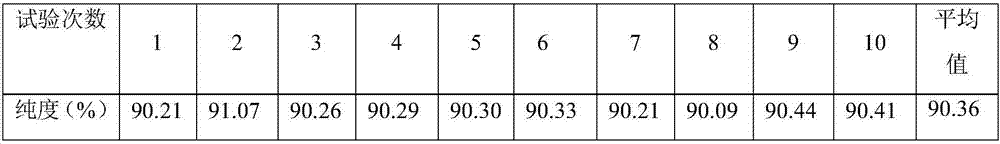

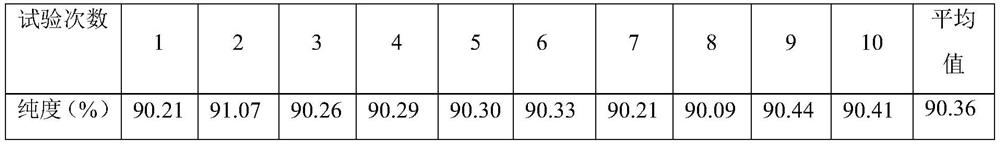

Method using gas chromatographic method to measure purity of tri-n-octylamine

InactiveCN106680392AWide detection rangeSimple methodComponent separationChromatographic columnImpurity

The invention relates to a method using a gas chromatographic method to measure the purity of tri-n-octylamine. The method is characterized in that a detector of the method is a flame ionization detector FID; split sampling is used, and the split ratio is (50:1)-(100:1); a separation method adopts programmed temperature rising, the initial temperature of a chromatographic column is set as 30-100 DEG C, the temperature is risen to 250-300 DEG C at the speed of 10-30 DEG C / minute, and the temperature is kept for 2-10 minutes; the temperature of a vaporizing chamber is set as 250-300 DEG C; the temperature of the detector is set as 300-330 DEG C; a quantitative method uses an area normalization method, and the purity of the tri-n-octylamine is determined. The method is simple, fast, wide in impurity detecting range, high in accuracy and sensitivity and good in reproducibility.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

A kind of preparation method and application of film-coated organic bentonite

InactiveCN106076265BImprove production efficiencyLow costOther chemical processesWater contaminantsWater bathsAnhydrous ethanol

The invention discloses a method for preparing film-coated organic bentonite and its application, and belongs to the technical field of organic bentonite preparation. It solves the technical problem of low adsorption rate of organic bentonite in the prior art. The preparation method first mixes cetyltrimethylammonium bromide, absolute ethanol, and deionized water uniformly to obtain a mixed solution A, mixes the sodium-based bentonite and the obtained mixed solution A uniformly, oscillates in a water bath, and cools to room temperature After centrifugation, washing, drying, and sieving, the organic modified bentonite was prepared; then, tri-n-octylamine and sulfonated kerosene were shaken in a water bath at room temperature to obtain coating liquid B; finally, the organic modified bentonite and coating After the solution B is fully absorbed, the coated organobentonite is prepared after steps such as ultrasonication and aging. The film-coated organic bentonite prepared by the invention can be used to treat cadmium-containing wastewater, and has strong adsorption property and large adsorption capacity.

Owner:SHANDONG UNIV OF SCI & TECH

Efficient purifying method of trimethylindium

ActiveCN104817580AEasy to operateImprove the purification effectComponent separationSolid sorbent liquid separationStationary phasePurification methods

The invention relates to an efficient purifying method of trimethylindium, belonging to the technical field of compound purification. The purifying method comprises the following steps of (1) pouring a crude product of trimethylindium into a first chromatographic column with a stationary phase as filler, naturally and downwards flowing the crude product of trimethylindium by virtue of gravity, and collecting a solution when all the liquid flows up; (2) pouring the collected solution into a second chromatographic column with a stationary phase as surface grafted filler, naturally and downwards flowing the solution by virtue of gravity, and collecting the solution when all the liquid flows up; then, pouring the collected solution into the second chromatographic column, and repeating the operation 2-5 times, wherein the surface grafted filler is filler of which the surface is grafted with tri-n-octylamine; and (3) heating and disassembling the second chromatographic column treated in the step (2), and collecting by vacuumizing at the bottom of the chromatographic column to obtain purified trimethylindium. The purifying method disclosed by the invention is combined with a solid-liquid separation means, and a specific coordination agent is loaded on the filler, so that not only is the method simple, but also the purifying effect is further improved.

Owner:苏州普耀光电材料有限公司

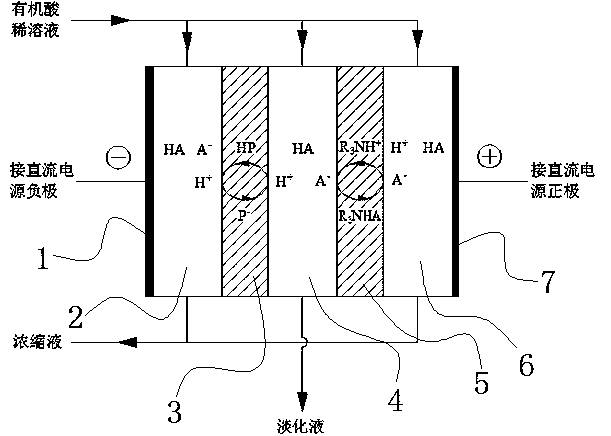

A method for enriching organic acid dilute solution by supporting liquid membrane electrodialysis

ActiveCN106334450BEasy to separateImprove mass transfer efficiencyElectrolysis componentsElectrolytic organic productionOrganic acidKerosene

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Efficient purification method of triethylgallium

ActiveCN104817579BEasy to operateImprove the purification effectComponent separationSolid sorbent liquid separationStationary phasePurification methods

The invention relates to an efficient purifying method of triethyl gallium, belonging to the technical field of compound purification. The purifying method comprises the following steps of firstly, filtering a crude product of triethyl gallium by using a first chromatographic column with a stationary phase as filler; and then, purifying the filtered crude product of triethyl gallium in a second chromatographic column with a stationary phase as surface grafted filler, wherein the surface grafted filler is filler of which the surface is grafted with tri-n-octylamine. The purifying method disclosed by the invention is combined with a solid-liquid separation means, and a specific coordination agent is loaded on the filler, so that not only is the method simple, but also the purifying effect is further improved.

Owner:苏州普耀光电材料有限公司

Method for extracting p-cumylphenol from phenol tar

ActiveCN107298636BSolve the current situation of low purityReduce loss rateOrganic chemistryOrganic compound preparationDimerPhysical chemistry

A method for extracting p-cumylphenol in phenol tar, comprising the steps: (1) phenol tar is subjected to vacuum distillation to obtain key components; the key components are p-cumylphenol, acetophenone, (2) The solvent is added dropwise to the key components, the drop rate is controlled at 55 drops to 65 drops / min, and then the temperature is slowly raised from room temperature to 313K to 323K, and the temperature rises During the process, uniform and slow stirring is required, and the solvent is composed of tri-n-octylamine and octylamine; the mass ratio of tri-n-octylamine to octylamine is: tri-n-octylamine:octylamine=80~85:20~15 The use of this extractant solves the current situation that the purity of p-cumylphenol extracted from phenol tar is not high. At the same time, the mixture of tri-n-octylamine and octylamine also has the advantages of low loss rate and easy recovery as the extractant.

Owner:PETROCHINA CO LTD

Efficient purification method of trimethylindium

ActiveCN104817580BEasy to operateImprove the purification effectComponent separationSolid sorbent liquid separationStationary phaseIndium

The invention relates to an efficient purifying method of trimethylindium, belonging to the technical field of compound purification. The purifying method comprises the following steps of (1) pouring a crude product of trimethylindium into a first chromatographic column with a stationary phase as filler, naturally and downwards flowing the crude product of trimethylindium by virtue of gravity, and collecting a solution when all the liquid flows up; (2) pouring the collected solution into a second chromatographic column with a stationary phase as surface grafted filler, naturally and downwards flowing the solution by virtue of gravity, and collecting the solution when all the liquid flows up; then, pouring the collected solution into the second chromatographic column, and repeating the operation 2-5 times, wherein the surface grafted filler is filler of which the surface is grafted with tri-n-octylamine; and (3) heating and disassembling the second chromatographic column treated in the step (2), and collecting by vacuumizing at the bottom of the chromatographic column to obtain purified trimethylindium. The purifying method disclosed by the invention is combined with a solid-liquid separation means, and a specific coordination agent is loaded on the filler, so that not only is the method simple, but also the purifying effect is further improved.

Owner:苏州普耀光电材料有限公司

Method using oxidization wastewater generated during DSC acid production to prepare direct yellow dye

The invention relates to a method using oxidization wastewater generated during DSC acid production to prepare direct yellow dye. The method includes the steps of firstly, filtering the oxidization wastewater generated during DSC acid production to remove sodium sulfate and DNS to obtain concentration, and measuring amino content; secondly, adding a tri-n-octylamine solution into the concentrate obtained in the first step, taking upper-layer oil, and washing the upper-layer oil with water; thirdly, adding water and alkali into the oil phase obtained in the second step; fourthly, regulating thesolution obtained in the third step with acid, and taking oil phase; fifthly, adding water into the oil phase obtained in the fourth step, and adding ethanolamine by using the amino content measuredin the first step as the reference; sixthly, subjecting the mixture obtained in the fifth step to standing and layering, wherein the lower-layer water phase is the direct yellow dye. The method has the advantages that a wastewater treatment process can be simplified, wastewater treatment cost can be lowered, and organic components such as various aromatic compounds containing nitro, water-solublesulfonic groups and carboxylic acid groups in the oxidation wastewater are sufficiently utilized to prepare the direct yellow dye.

Owner:ZHEJIANG HONGDA CHEM

Preparation method of high-purity triethyl gallium

ActiveCN104774216AEasy to operateImprove purification effectGroup 3/13 element organic compoundsSolventChromatographic column

The invention relates to a preparation method of high-purity triethyl gallium, belonging to the technical field of preparation of compounds of Group 3 metals in the periodic table. The preparation method comprises the following steps: (1) preparing a triethyl gallium crude product by using aether as a solvent; and (2) purifying the triethyl gallium crude product obtained in the step (1), wherein a first chromatographic column is utilized to purify the triethyl gallium crude product and adopts grafted silicon dioxide as a stationary phase, and the grafted silicon dioxide is silicon dioxide with tri-n-octyl amine grafted on the surface. The preparation method adopts the two steps of synthesis and separation to obtain the triethyl gallium of which the purity can reach 6N. The purification method combines the solid-liquid separation means to load the specific complexant onto the silicon dioxide; and thus, the method is simple to operate and further enhances the purification effect.

Owner:苏州普耀光电材料有限公司

A kind of preparation method of tri-n-octylamine

ActiveCN107540557BRealize comprehensive utilizationReduce the discharge of three wastesMetal/metal-oxides/metal-hydroxide catalystsAmino compound preparation by condensation/addition reactionsAlkaline earth metalPtru catalyst

The invention discloses a tri-n-octylamine preparation method. The preparation method comprises the following preparation steps: throwing di-n-octylamine, n-caprylic alcohol and an alkaline earth metal oxide catalyst into a reactor; keeping hydrogen atmosphere after nitrogen displacement and hydrogen displacement are performed, reducing the catalyst for 1+ / -0.5 hour at 160 to 190 DEG C; heating and reacting, sampling and performing GC detection when the collected generated water amount reaches 95 percent or above a theoretical amount and the change amount in half an hour does not exceed 2 weight percent, and ending the reaction to obtain crude tri-n-octylamine when the content of the di-n-octylamine is less than or equal to 2 weight percent; cooling, precipitating the crude tri-n-octylamine, and finally, rectifying to obtain the tri-n-octylamine. According to the process route, the initial raw materials come from distillation residues of the tri-n-octylamine; a byproduct of the companyis changed from waste into treasure, so that waste utilization is realized; the emission of waste water, waste gas and solid waste is reduced; the environmental protection is benefited; the economicbenefit is increased.

Owner:江苏万盛大伟化学有限公司

Refined monochloroacetic acid crystalline product complexometric extraction method

InactiveCN102731287BReduce energy consumptionHigh separation selectivityCarboxylic compound separation/purificationAliphatic amineChloroacetic acid

The invention discloses a refined monochloroacetic acid crystalline product complexometric extraction method. The method comprises: first using the normal hexane solution of aliphatic amine to carry out complexometric extraction to obtain the water solution of the monochloroacetic acid crystalline product (quality purity about 99.0%), standing for layering with the upper phase being an organic phase and the lower phase being a water phase, then using the normal hexane to extract the water phase, and vaporizing the water phase to obtain a solid which is the refined monochloroacetic acid (quality purity above 99.9%). The key in the technology is the employed aliphatic amine is a mixture of tri-n-octylamine and di-n-octylamine. As a complexometric extraction agent, the mixture can effectively remove the main impurity of dichloroacetic acid in the monochloroacetic acid crystalline product.

Owner:ZHEJIANG UNIV

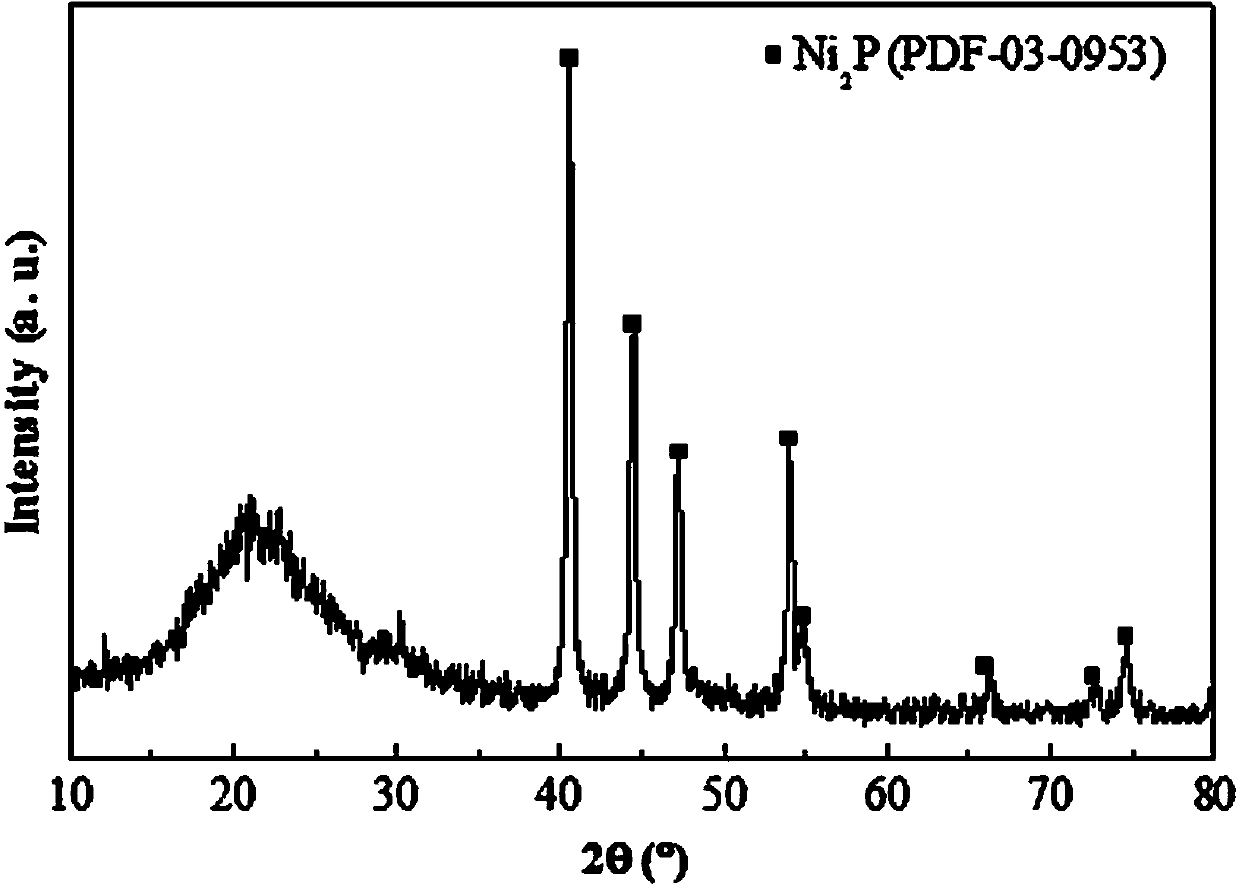

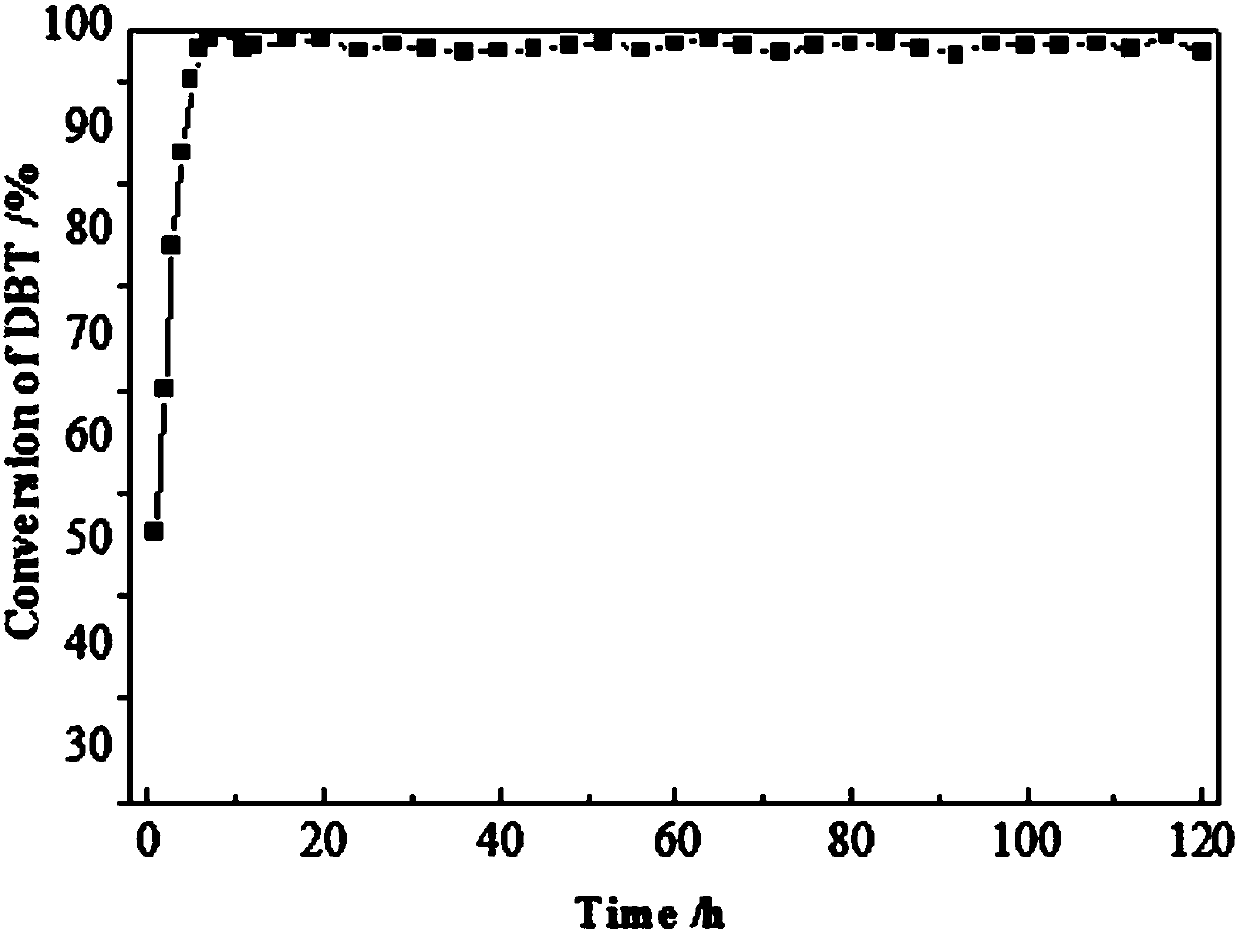

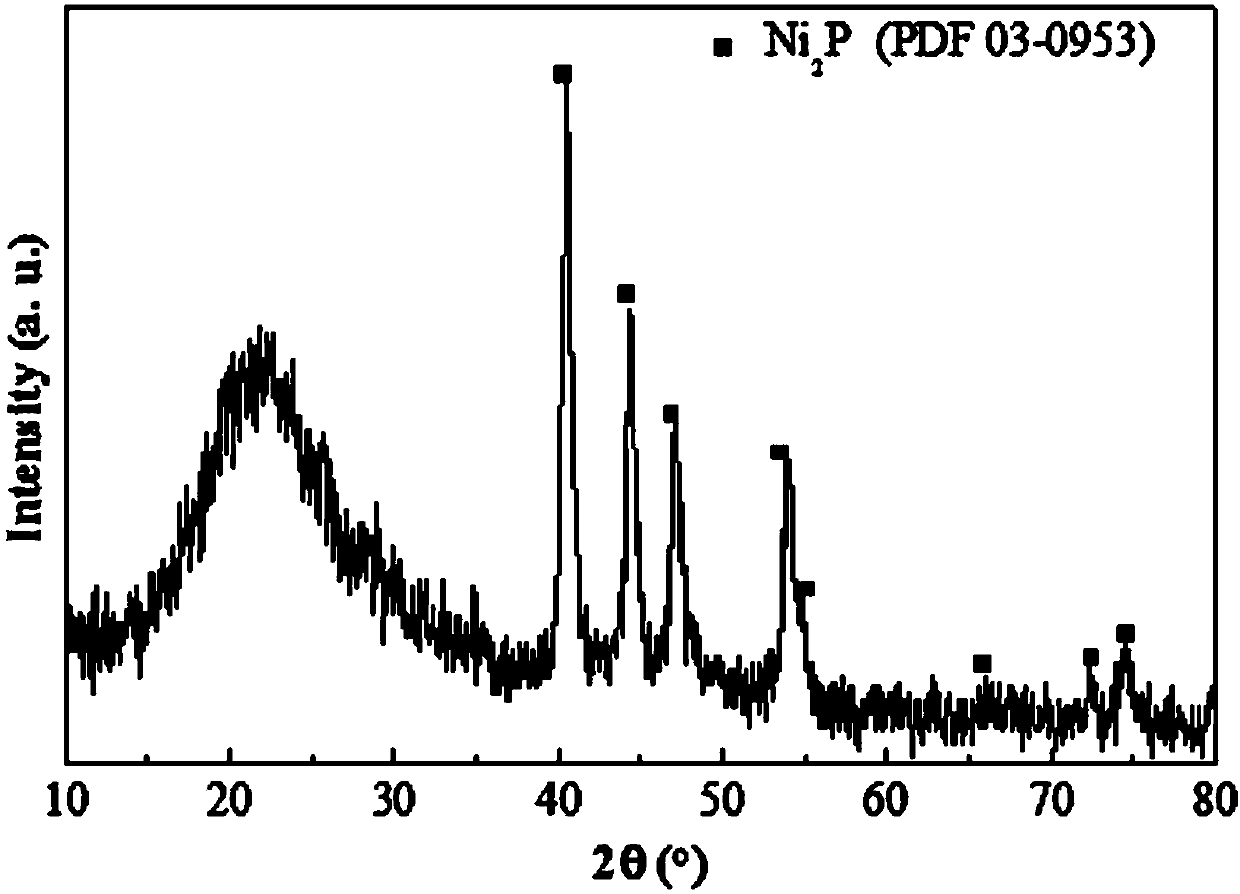

Method for preparing supported oil product hydrodesulphurization catalyst with solvothermal method at normal pressure

InactiveCN102836739BHigh activityImprove stabilityMolecular sieve catalystsHydrocarbon oils refiningPtru catalystHydrodesulfurization

The invention discloses a method for preparing supported oil product hydrodesulphurization catalyst with solvothermal method at normal pressure. The method comprises the following steps: adding acetylacetone nickel, triphenyl phosphine and MCM-41 interface confucius screen to tri-n-octylamine, and evenly stirring a mixture at room temperature; adding slurry obtained in the first step to a normal-pressure stirring reactor, heating the slurry to 330 DEG C with an increment of 2 DEG C per minute in nitrogen flow of 100mL / min; keeping the temperature constantly for 3 hours, and reducing the temperature to the room temperature, finally, passivating the slurry for 1 hour by O2 / N2 mixing gas containing 10% of oxygen; filtering the passivated slurry under reduced pressure by a sand-core hopper; washing an obtained filter cake with mixed solution of ethanol and carbon tetrachloride based on volume ratio of 1: 1 at 50 DEG C; and drying the filter cake at 100 DEG C and tabletting the filter cake so as to obtain a catalyst finished product. According to the invention, the prepared supported oil product hydrodesulphurization catalyst disclosed by the invention has the advantages of soft condition, little dependence on equipment, little impurity and high desulphurization rate.

Owner:NORTHEAST GASOLINEEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com