Phase-transfer catalytic oxidation extraction desulphurization method for gasoline

A technology of phase transfer catalysis and phase transfer catalyst, which is applied in the direction of multi-stage series refining process treatment, etc., can solve the problems of low gasoline yield, etc., and achieve the effect of high gasoline desulfurization rate and gasoline yield, and good desulfurization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] With the molar ratio of concentrated sulfuric acid and tri-n-octylamine 1:1, at room temperature, the acid was added dropwise to react with tri-n-octylamine in a 250mL flask for 1 hour to obtain tri-n-octylamine sulfate, which was placed in a brown bottle Medium, keep away from light, and reserve.

[0021] Weigh 50ml (55.2g) hydrogen peroxide (hydrogen peroxide mass content is 30%) and 0.552g sodium tungstate (1.0% of hydrogen peroxide solution quality), 0.3g trin-octylamine sulfate phase-transfer catalyst (hydrogen peroxide mass content is 30%) respectively 0.5%), moved to a 250ml three-necked flask, stirred and mixed at room temperature for 5min to obtain an oxidation solution; weighed 100ml (71.4g) catalytically cracked gasoline with a sulfur content of 187.1 μg / g, and moved it to a three-necked flask of an oxidation solution, Stir the reaction in a water bath at 30°C for 20 minutes; then pour the reaction mixture into a separatory funnel and let it stand for 20 minu...

Embodiment 2~ Embodiment 4

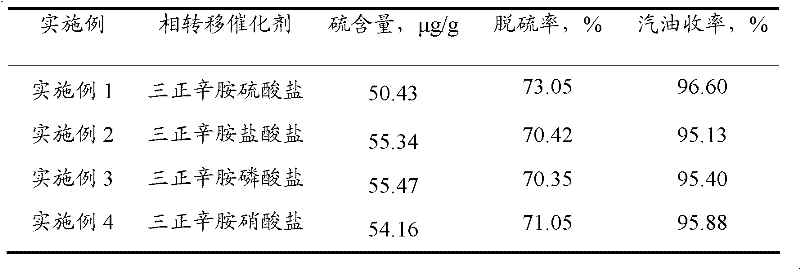

[0024] Three kinds of acids were used to react with tri-n-octylamine to synthesize three kinds of tri-n-octylamine inorganic acid salt phase transfer agents, and gasoline desulfurization experiments were carried out under the conditions of Example 1. The experimental results are listed in Table 1 together. Comparing the data in Table 1, it can be seen that the phase transfer catalytic desulfurization effect of tri-n-octylamine sulfate is better.

[0025] Table 1

[0026]

Embodiment 5~ Embodiment 8

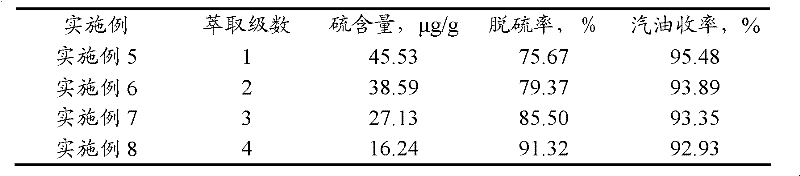

[0028] Tri-n-octylamine sulfate was used as a phase transfer agent, the oxidation reaction temperature was 60°C, and other desulfurization experimental conditions were the same as in Example 1. The experimental results of oxidized gasoline extracted at different stages are listed in Table 2. It can be seen from Table 2 that as the number of extraction stages increases, the gasoline desulfurization rate continues to increase, while the gasoline yield continues to decrease.

[0029] Table 2

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com