Method for preparing different shaped nano zinc oxide by thermal decomposition

A nano-zinc oxide, thermal decomposition technology, applied in the direction of zinc oxide/zinc hydroxide, etc., to achieve the effects of good controllability, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

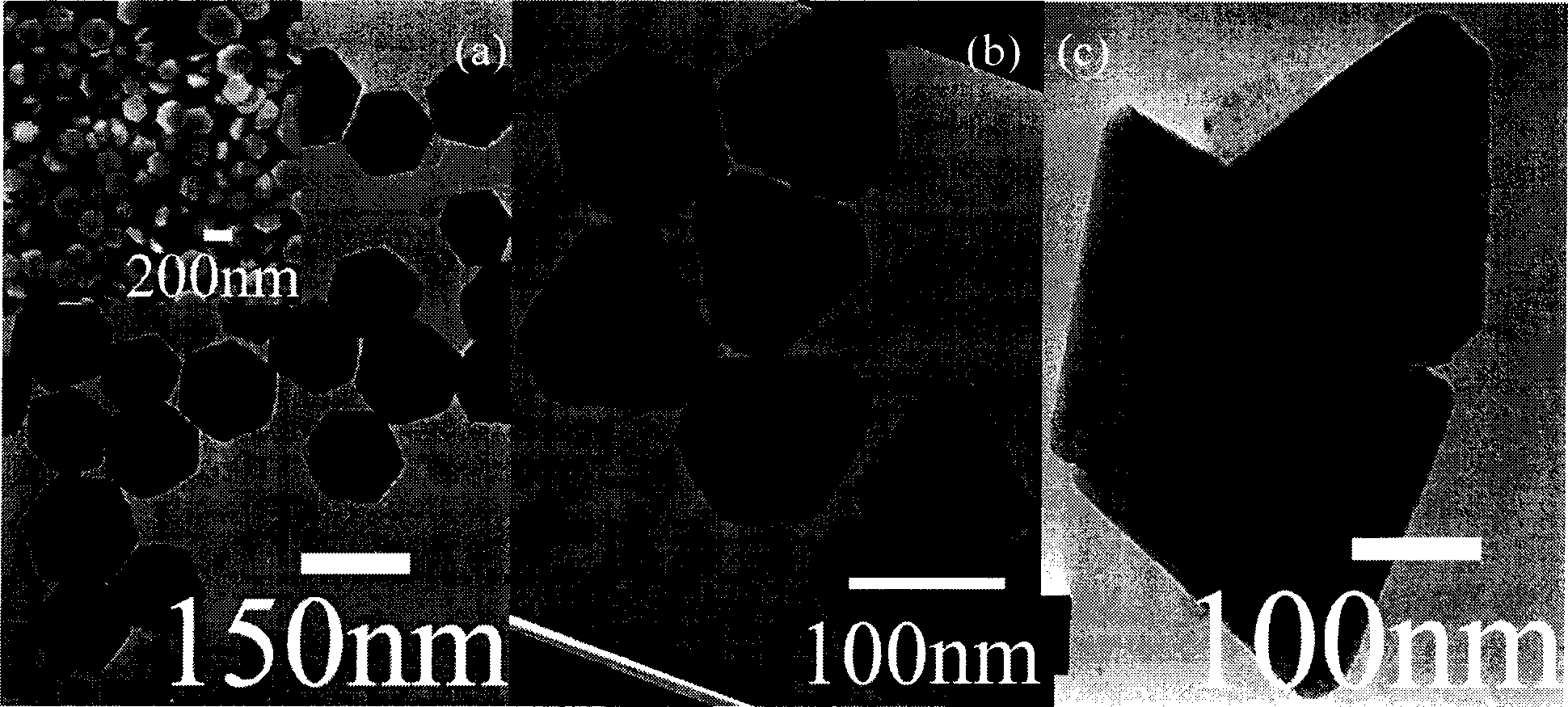

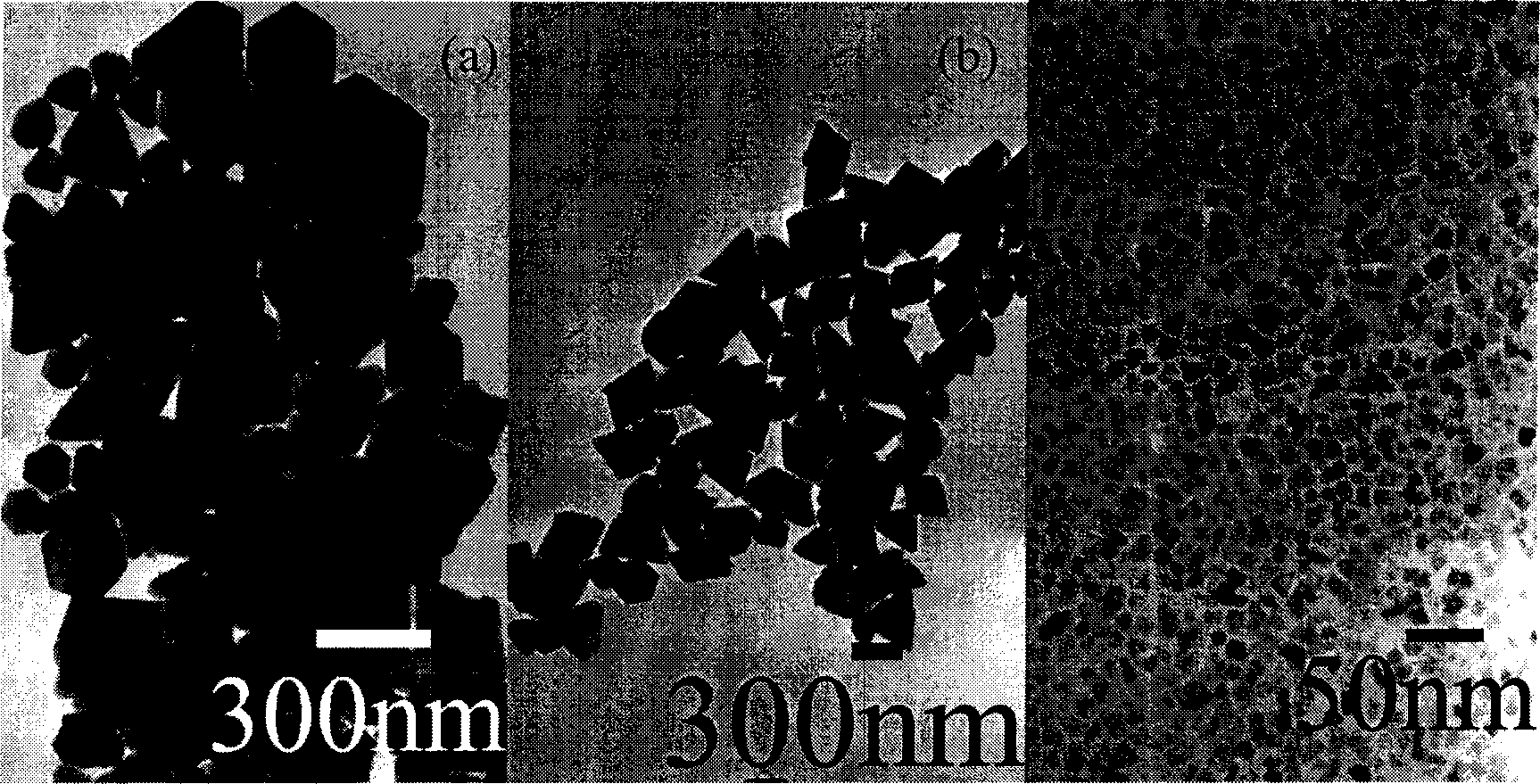

Embodiment 1

[0022] According to the preparation process, 5×10 -4 mol Zn(Ac) 2 2H 2 O was mixed with 5ml of absolute ethanol, and the reaction vessel was placed in a water bath with magnetic stirring and heated to 70°C. will be 1.5×10 -3 mol oleic acid was added to 10ml trioctylamine and mixed, and the mixed solution was heated to 80°C at a heating rate of 4°C / min. Then inject the ethanol solution of zinc acetate into the mixed solution of oleic acid and trioctylamine quickly through a medical syringe and heat it. After the ethanol in which the zinc acetate is dissolved is volatilized, the mixed solution is heated to 360°C under mechanical stirring and a heating rate of 3°C / min. The reaction was stopped after reflux at 360° C. for 30 min. Add 15ml of absolute ethanol to the reacted mixture, and precipitation can be observed. The mixture is centrifuged at a speed of 10000r / min for 45 minutes through a SORVALL LEGEND-T centrifuge, and the product is washed with 30ml of absolute ethanol a...

Embodiment 2

[0024] According to the preparation process, 5×10 -4 mol Zn(Ac) 2 2H 2 O was mixed with 6ml of absolute ethanol, and the reaction vessel was placed in a water bath with magnetic stirring and heated to 70°C. will be 1.5×10 -3 mol oleic acid was added to 12ml trioctylamine and mixed, and the mixed solution was heated to 90°C at a heating rate of 4°C / min. Then inject the ethanol solution of zinc acetate into the mixed solution of oleic acid and trioctylamine quickly through a medical syringe and heat it. After the ethanol in which the zinc acetate is dissolved is volatilized, the mixed solution is heated to 355°C under mechanical stirring and a heating rate of 2°C / min. The reaction was stopped after refluxing at 355° C. for 60 min. Add 18ml of absolute ethanol to the reacted mixture, and precipitation can be observed. The mixture is centrifuged at a speed of 10000r / min for 30 minutes through a SORVALL LEGEND-T centrifuge, and the product is washed with 35ml of absolute ethano...

Embodiment 3

[0026] According to the preparation process, 5×10 -4 mol Zn(Ac) 2 2H 2 O was added to 10ml of absolute ethanol and mixed, and the reaction vessel was placed in a water bath with magnetic stirring and heated to 70°C. will be 1.5×10 -3mol oleic acid was added to 8ml trioctylamine and mixed, and the mixed solution was heated to 100°C at a heating rate of 4°C / min. Then inject the ethanol solution of zinc acetate into the mixed solution of oleic acid and trioctylamine through a medical syringe and heat it. After the ethanol in which the zinc acetate is dissolved evaporates, the mixed solution is heated to 350°C under mechanical stirring and a heating rate of 2°C / min. The reaction was stopped after reflux at 350° C. for 180 min. Add 15ml of absolute ethanol to the reacted mixture, and it can be observed that there is precipitation. The mixture is centrifuged at a speed of 10000r / min for 30 minutes through a SORVALLLEGEND-T centrifuge, and the product is washed with 35ml of absol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com