Preparation method of monoclinic phase ditetrahedron bismuth vanadate crystal

A bismuth tetrahedron and bismuth vanadate technology, which is applied in chemical instruments and methods, vanadium compounds, inorganic chemistry, etc., can solve the problem of not finding nano-scale bismuth tetrahedral bismuth vanadate, and achieve good dispersion and low energy consumption. The effect of low, uniform size and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) 0.00177molBi(NO 3 ) 3 ·5H 2 O dissolved in 30 mL 1mol / L HNO 3 solution, and added 1.3g NaOH to obtain mixed solution A;

[0031] Mix n-octanoic acid and toluene (total volume is 30 mL) to obtain solution B;

[0032] (2) Mix solution A and solution B, stir at room temperature for 30 minutes, stand still for 10 minutes, extract through a separatory funnel, and take upper solution C;

[0033] (3) 0.00177mol NaVO 3 Dissolve in 30 mL of HNO at pH = 0.5 3 Get solution D;

[0034] Mix tri-n-octylamine and toluene (the total volume is 30 mL) to obtain solution E;

[0035] (4) Mix solution D and solution E, stir at room temperature for 30 minutes, stand still for 10 minutes, extract through a separatory funnel, and take upper solution F;

[0036](5) Mix solution C and solution F, add 3.0 mL of oleylamine, and stir for 30 minutes to obtain solution G;

[0037] (6) Put solution G in a polytetrafluoroethylene container, react at 160°C for 20 hours, cool to room te...

Embodiment 2

[0043] The present embodiment prepares the method for bismuth vanadate all the other to be identical with embodiment 1, difference is in step (1): add 1.4g NaOH; In step (3): HNO 3 The pH is 0.45:; in step (5): the amount of oleylamine added is 3.2mL; step (6): solution G is reacted at 180°C for 20 hours.

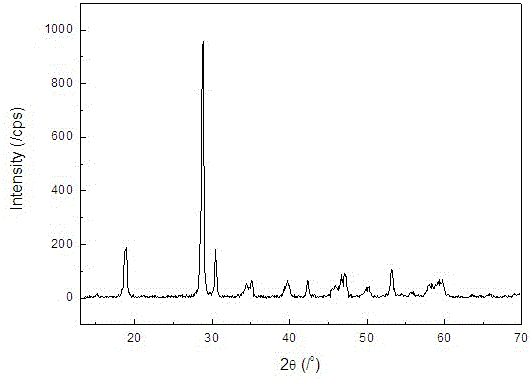

[0044] as attached Figure 4 As shown, it is the XRD pattern of the double tetrahedral bismuth vanadate nanopowder prepared in this embodiment, and it can be seen that its purity is relatively high.

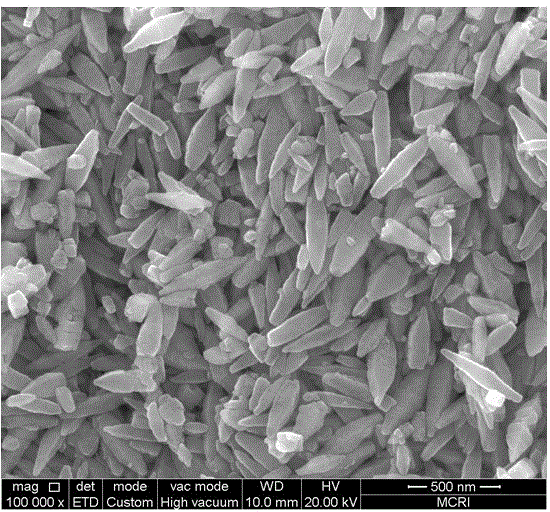

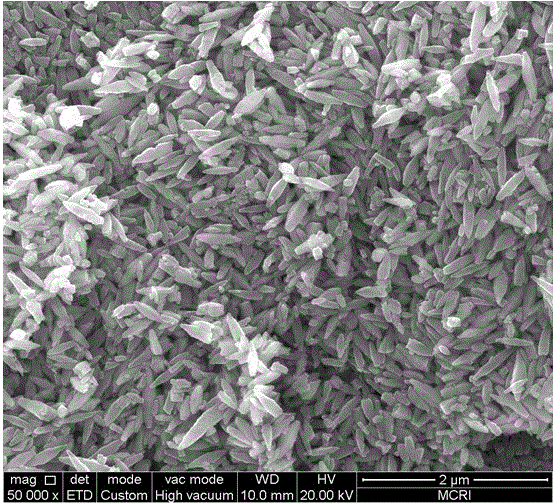

[0045] as attached Figure 5 As shown, it is the SEM image of the double tetrahedral bismuth vanadate nanopowder prepared in this embodiment, its magnification is 100000 times, and the obtained sample has initially appeared double tetrahedral crystals, and this stage is in the direction of double tetrahedral vanadium bismuth acid transition state.

[0046] The invention adopts a simple solvothermal preparation process to prepare ditetrahedral bismuth vanadate crystals with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com