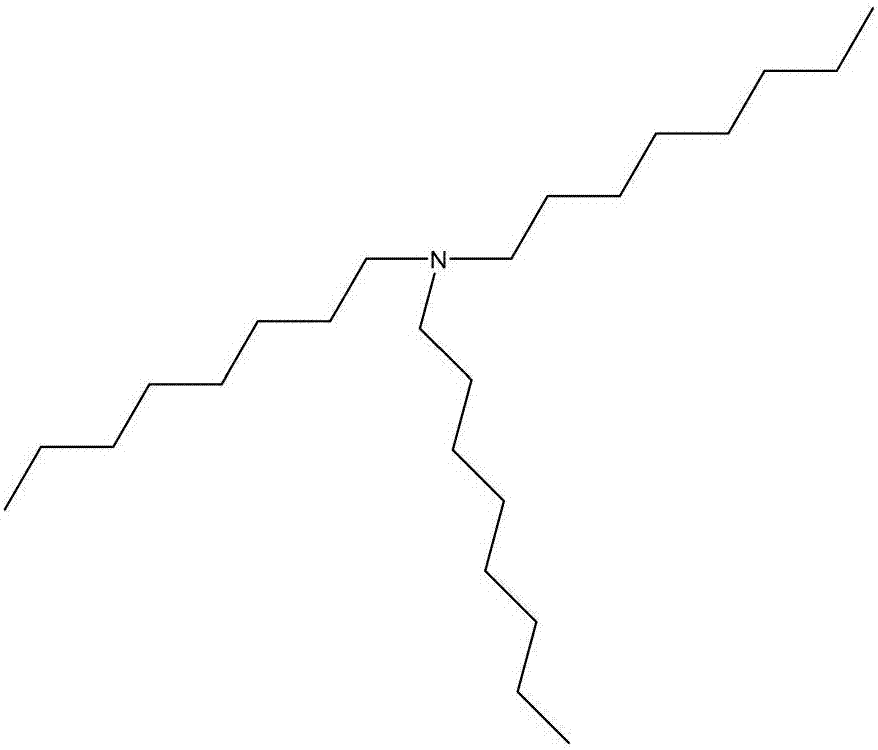

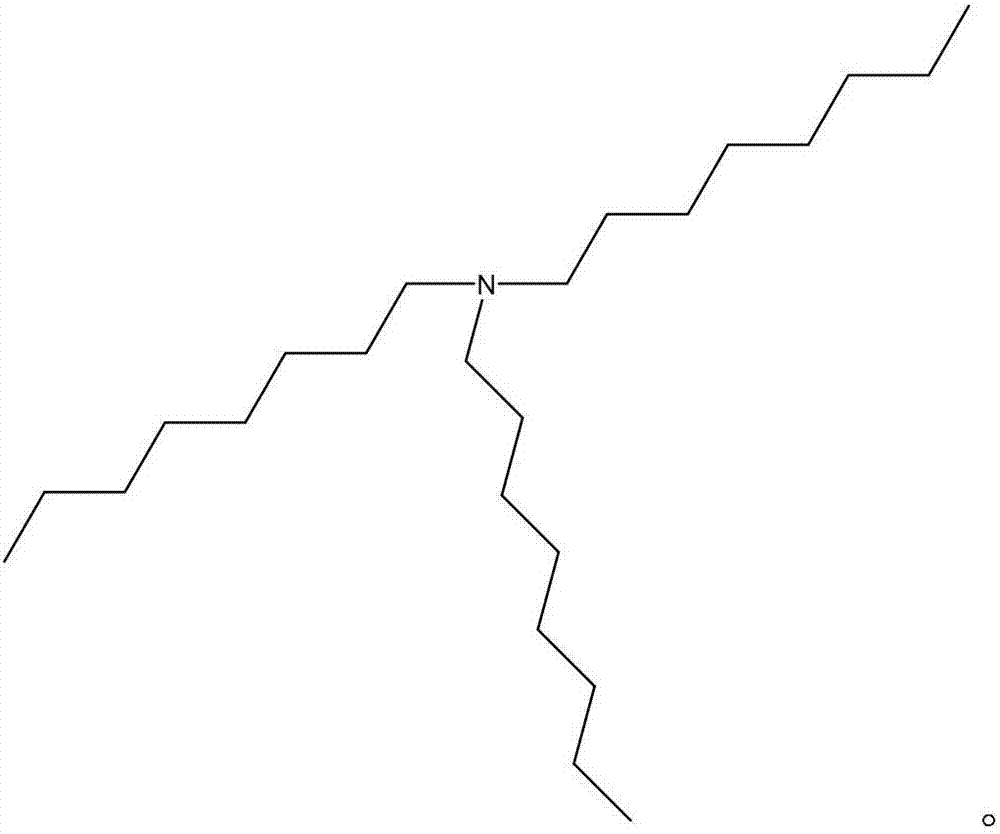

Tri-n-octylamine preparation method

A technology of tri-n-octylamine and di-n-octylamine, which is applied in the field of preparation of tri-n-octylamine, can solve the problem of cost, is not suitable for industrialized production, etc., and achieves the effects of reducing three-waste discharge, realizing waste utilization, and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Preparation of alkaline earth metal oxide catalysts: Cu(NO 3 )2·3H 2 O, Ni (NO 3 )2·6H 2 O, Zn (NO 3 )2·6H 2 O, Mg (NO 3 )2·6H 2 O was dissolved in water, neutralized with sodium carbonate to neutrality, then ZrO was added 2 As a catalyst carrier, stir evenly into a paste, age in a water bath at 50±5°C for 5±1h, dry with suction filtration, calcinate at 450±10°C for 4±0.5h, and crush to below 400 mesh to obtain alkaline earth metal oxides catalyst.

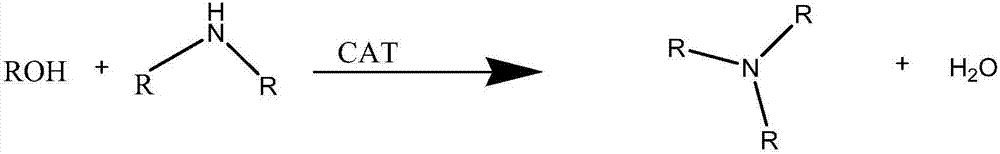

[0047] Put 150 g of di-n-octylamine, 89 g of n-octanol, and 1.5 g of alkaline earth metal oxide catalyst into a 500-milliliter four-neck reaction flask, which is equipped with a hydrogen circulation and water separation device. After nitrogen replacement and hydrogen replacement, the catalyst was reduced under a hydrogen atmosphere at 160-180 ° C for 1 hour, and then the reaction temperature was increased to 210-220 ° C, and water was continuously generated in the reaction. Di-n-octylamine 0.8%, tri-n-octylamine 94...

Embodiment 2

[0049] Preparation of alkaline earth metal oxide catalysts: Cu(NO 3 )2·3H 2 O, Ni (NO 3 )2·6H 2 O, Zn (NO 3 )2·6H 2 O, Mg (NO 3 )2·6H 2 O was dissolved in water, neutralized with ammonia water to neutrality, then calcium carbonate was added as a catalyst carrier, stirred to form a paste, aged in a water bath at 50±5°C for 5±1h, dried by suction filtration, and roasted at 450±10°C for 4 ±0.5h, crushed to less than 400 mesh, namely the alkaline earth metal oxide catalyst was obtained.

[0050] Put 150 g of di-n-octylamine, 97.2 g of n-octanol, and 3 g of alkaline earth metal oxide catalyst into a 500-milliliter four-necked reaction bottle with a hydrogen circulation and water separation device. After nitrogen replacement and hydrogen replacement, the catalyst was reduced under a hydrogen atmosphere at 160-190 ° C for 1 hour, and then the reaction temperature was raised to 200-230 ° C, and water was continuously generated in the reaction. Di-n-octylamine 0.3%, tri-n-octyl...

Embodiment 3

[0052] Preparation of alkaline earth metal oxide catalysts: Cu(NO 3 )2·3H 2 O, Ni (NO 3 )2·6H 2 O, dissolved in a certain amount of water, neutralized with ammonia water to neutrality, and then added calcium carbonate as a catalyst carrier, stirred uniformly into a paste, aged in a water bath at 50±5 °C for 5±1 h, and dried by suction filtration, 450± The alkaline earth metal oxide catalyst was prepared by roasting at 10°C for 4±0.5h and crushing to below 400 mesh.

[0053]Put 150 g of di-n-octylamine, 97.2 g of n-octanol, and 3 g of an alkaline earth metal oxide catalyst into a 500 ml four-necked reaction flask equipped with a hydrogen circulation and water separation device. After nitrogen replacement and hydrogen replacement, reduce the catalyst under a hydrogen atmosphere at 160-190°C for 1 hour, then raise the reaction temperature to 200-230°C, water will continue to be generated during the reaction, and after 4 hours there is almost no water, then sample GC analysis, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com