Method for separating and recovering gold or silver by inner-coupling liquid membrane

A liquid membrane separation and internal coupling technology, applied in the field of internal coupling liquid membrane separation and recovery of gold, and internal coupling liquid membrane separation and recovery of silver, can solve the problems of complex device structure, high cost, difficulty in mass production, etc., and achieve recycling selectivity. High, cost-saving and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: according to the method for above-mentioned recovery gold, implement according to the following steps:

[0040] Step 1. Add KCl and HCl to the feed liquid to be recovered to make the H in the feed liquid phase + The ion concentration is 2mol / L, K + Ion concentration is 2mol / L; liquid film phase 2 is prepared: the liquid film phase is composed of TOA, TBP and organic solvent kerosene, wherein the mass fraction of TOA is 15%, the mass fraction of TBP is 5%, and the rest is kerosene; preparation of back extraction Solution: Mix KCN with a concentration of 0.1mol / L and KCl with a concentration of 2mol / L in a certain proportion.

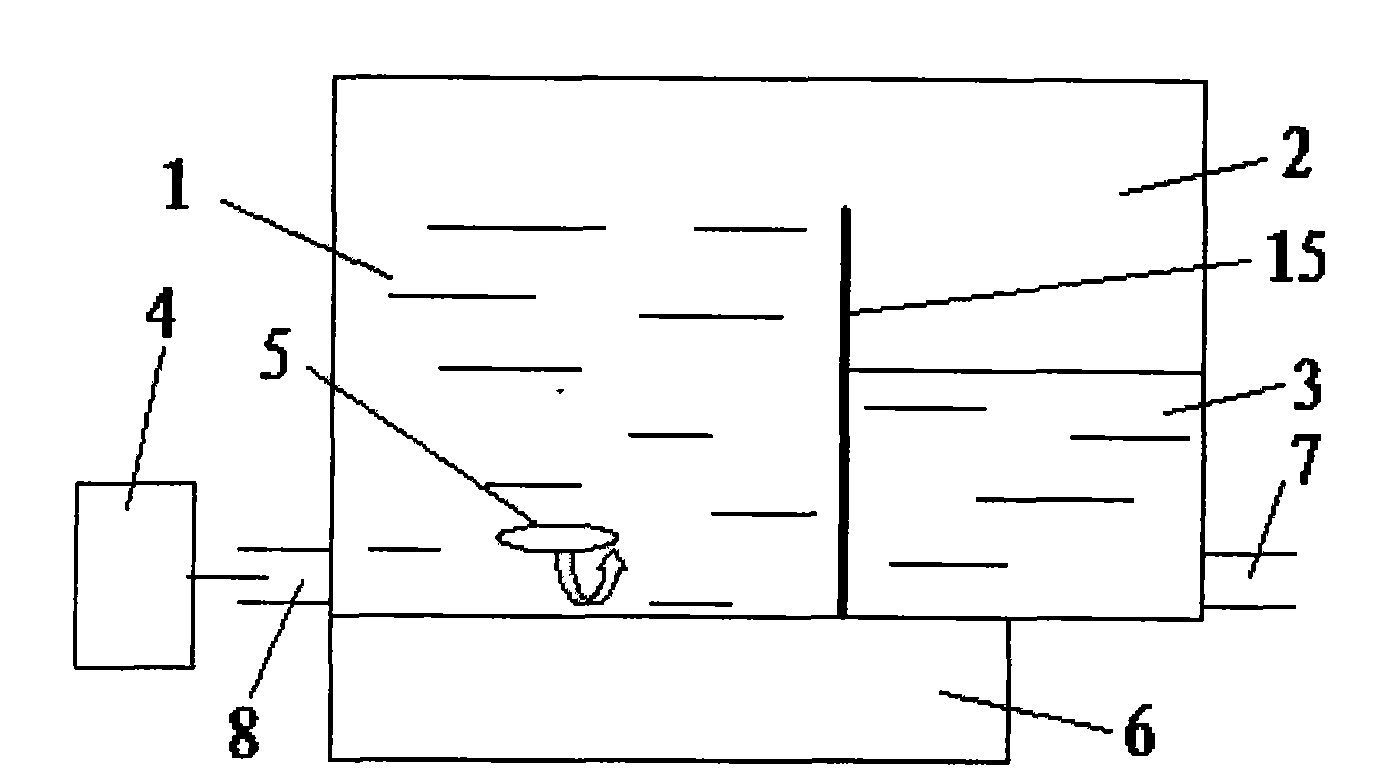

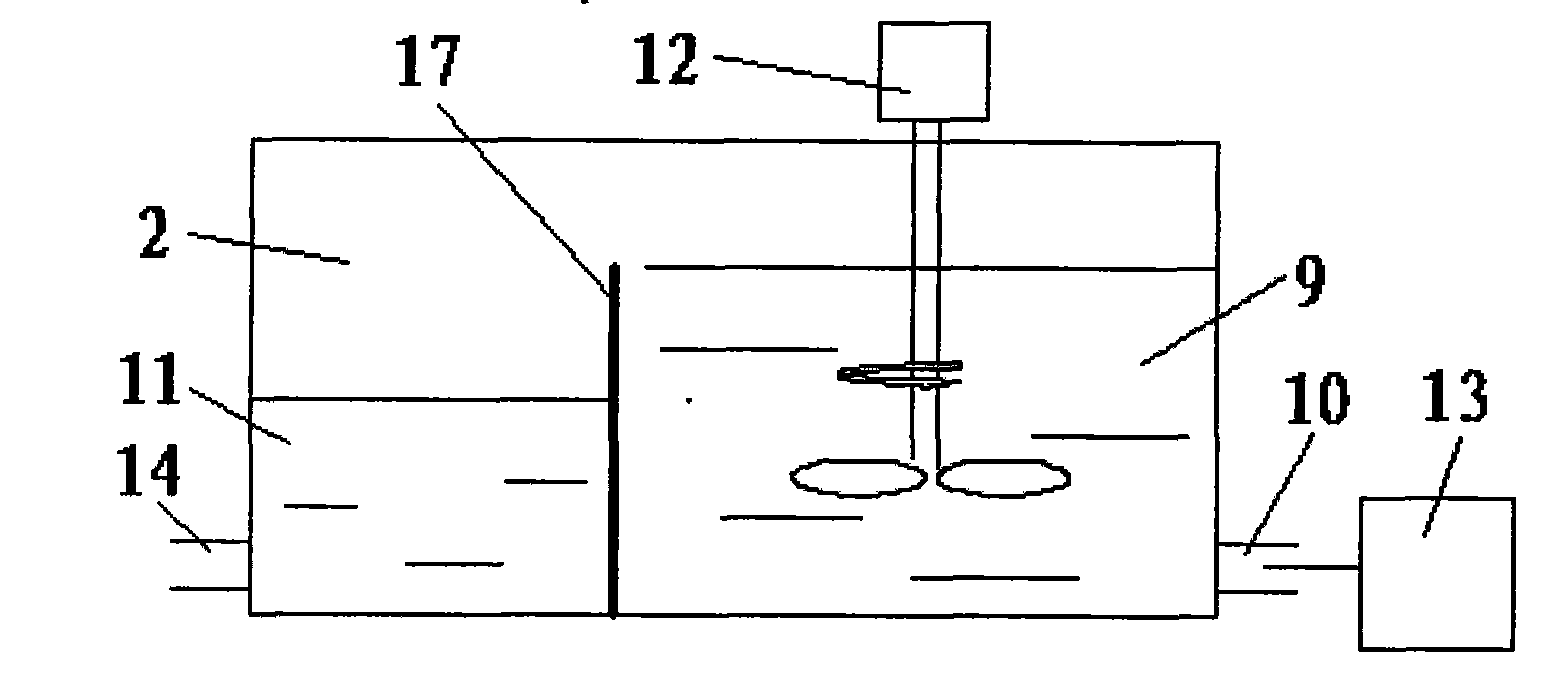

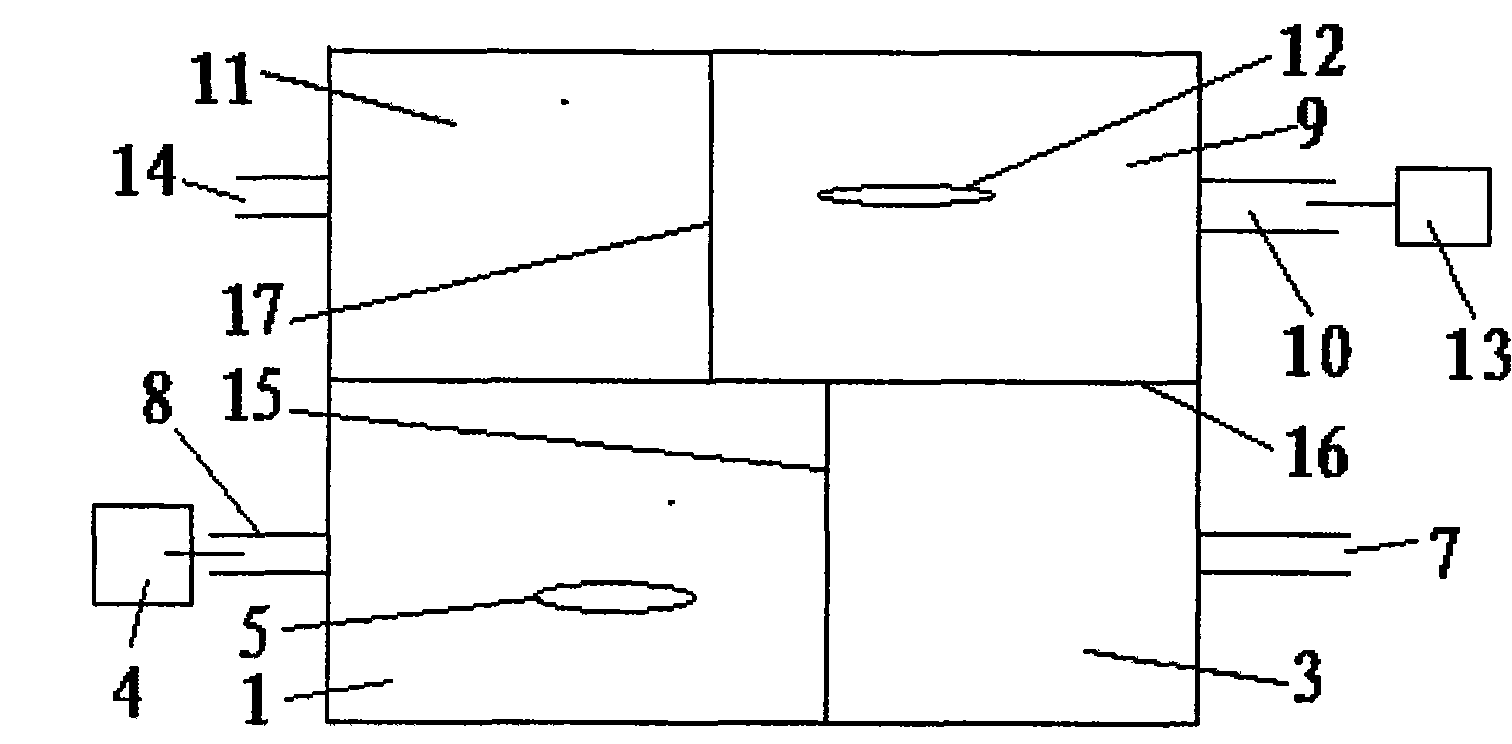

[0041] Such as image 3 , add a certain volume of liquid film phase 2 into the extraction mixing chamber 1, the extraction clarification chamber 3, the stripping mixing chamber 9 and the stripping clarification chamber 11.

[0042] Step 2, extraction: as figure 1 , the feed liquid is sent into the extraction mixing chamber 1 from ...

Embodiment 2

[0045] Embodiment 2, according to the method for reclaiming gold of above-mentioned embodiment 1, control parameter is as follows:

[0046] Preparation liquid: in the Au to be recovered 3+ Add KCl and HCl to the ionic feed liquid, so that the H in the feed liquid phase + The ion concentration is 3mol / L, K + Ion concentration is 3mol / L; prepare liquid membrane phase 2: mix TOA, TBP and kerosene, wherein the mass fraction of TOA is 5%; KCl is mixed, wherein the concentration of KCN is 0.2mol / L, and the concentration of KCl is 1.5mol / L; During extraction, the rotating speed of magnetic stirrer 6 is controlled at 1200 rev / min; minute. The experimental results show that the recovery rate of gold can reach more than 95% after migrating for 2 hours.

Embodiment 3

[0047] Embodiment 3, according to the method for reclaiming gold of above-mentioned embodiment 1, control parameter is as follows:

[0048] Preparation liquid: in the Au to be recovered 3+ Add KCl and HCl to the ionic feed liquid, so that the H in the feed liquid phase + The ion concentration is 2.4mol / L, K + Ion concentration is 2.5mol / L; prepare liquid film phase 2: mix TOA, TBP and kerosene, wherein the mass fraction of TOA is 7.5%; the mass fraction of TBP is 10%, the rest is kerosene; Mix with KCl, wherein the concentration of KCN is 0.4mol / L, and the concentration of KCl is 1.8mol / L; During extraction, the rotating speed of magnetic stirrer 6 is controlled at 1500 rev / min; During stripping, the rotating speed of electric stirrer 12 is controlled at 1200r / minute. The experimental results show that: after migration for 2 hours, the recovery rate of gold can reach more than 90%, while the migration of copper, zinc, cadmium and lead is less than 5%, thus realizing the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com