High-strength coal ash waste glass aerated concrete block and processing method thereof

A technology for aerated concrete and waste glass, applied in solid waste management, climate sustainability, other household appliances, etc., can solve the problem of poor gas-generating effect of gas-generating agents, irregular shape of pores, and high collapse rate of aerated blocks problem, to achieve the effect of drying shrinkage, small drying shrinkage value, and obvious energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

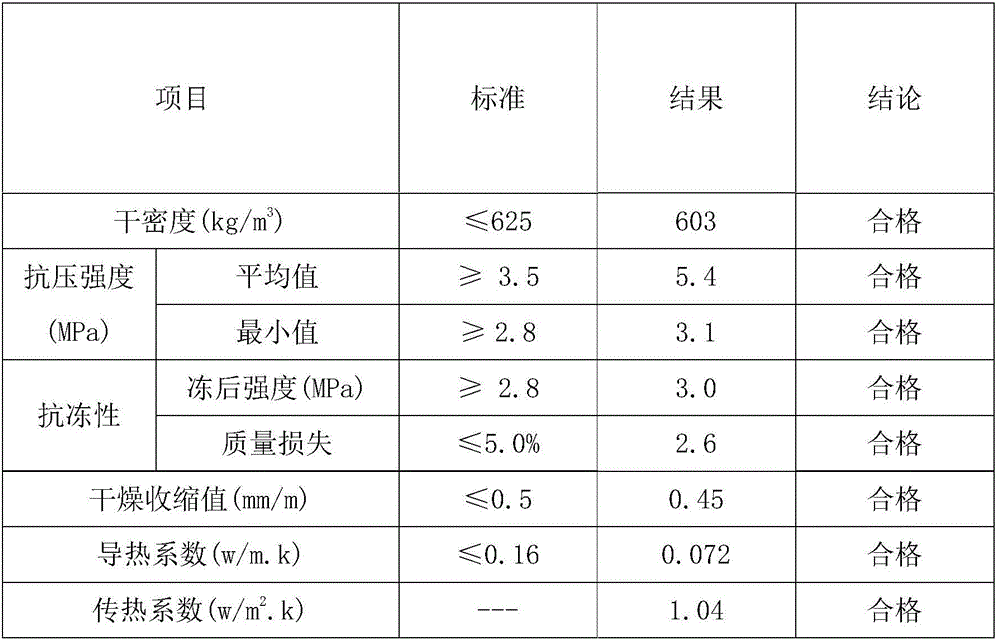

Image

Examples

Embodiment 1

[0019] Embodiment 1: a kind of high-strength fly ash waste glass aerated concrete block, the weight (kg) of its composition raw material is: fly ash 25, waste glass 37, gypsum 3, quicklime 4, kaolin 3, zeolite 3, Cement 5, hydroxypropyl methylcellulose 1, fruit shell activated carbon 2, appropriate amount of water, trin-octylamine 0.3, admixture 1, aluminum powder 2, oxidized starch 0.3, polyoxyethylene fatty alcohol ether 0.01, triterpene saponin 0.2 , sodium stearate 0.02, benzotriazole 0.03,

[0020] The admixture has the following weight (kg) components and raw materials mixed together: aerated concrete block waste 15, triethanolamine 0.3, urotropine 0.2, sodium rosinate 0.025, sodium lignin sulfonate 0.012, vinegar residue 2 , 3 quicklime, 0.6 borax, 0.3 dodecylbenzenesulfonic acid, appropriate amount of water, mixed at high speed.

[0021] The processing method of high-strength fly ash waste glass aerated concrete block comprises the following steps:

[0022] (1) Weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com