Method for preparing supported oil product hydrodesulphurization catalyst with solvothermal method at normal pressure

A solvothermal and hydrodesulfurization technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. Agglomeration and other problems, to achieve the effect of high catalytic hydrodesulfurization performance, cheap raw materials, high activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

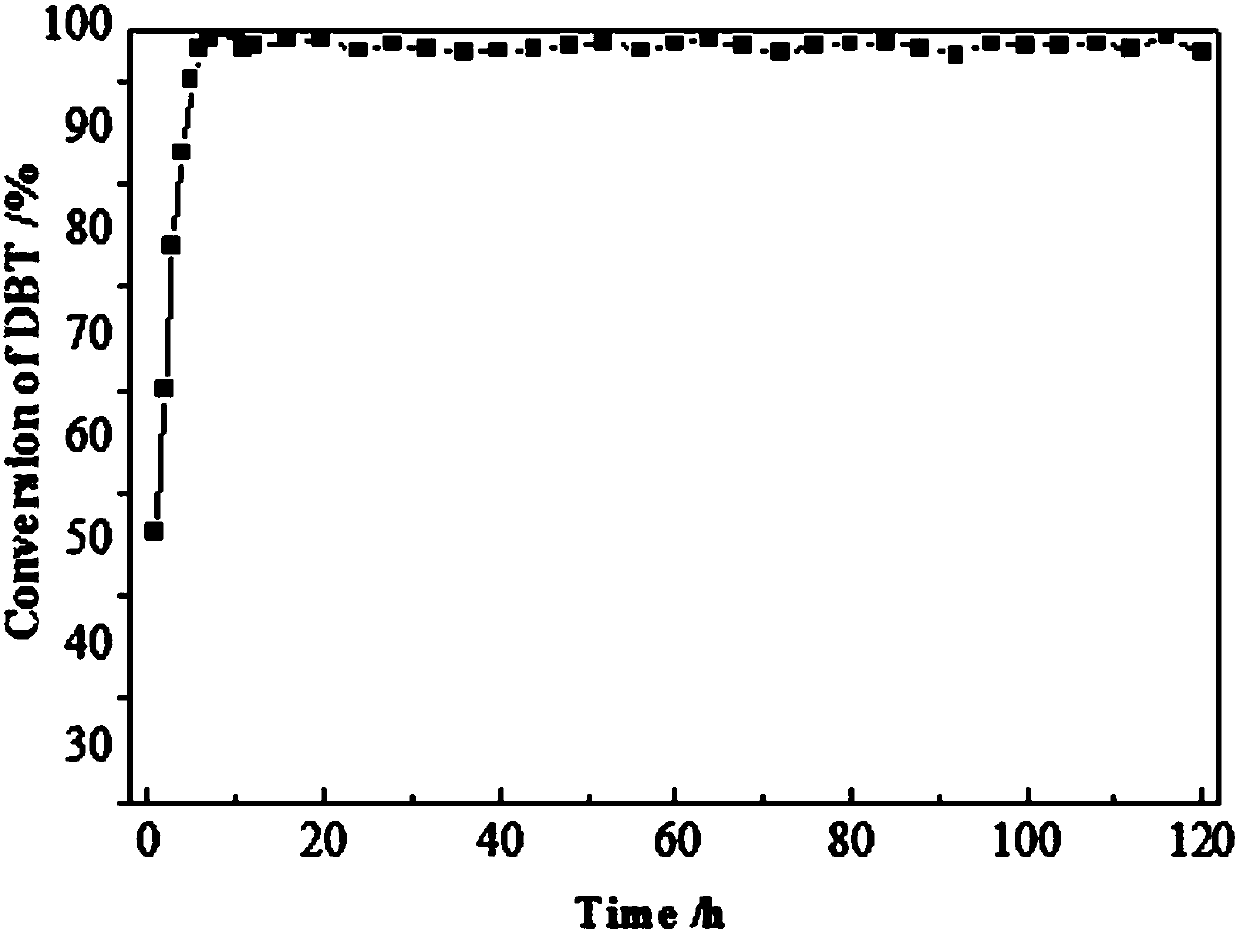

Examples

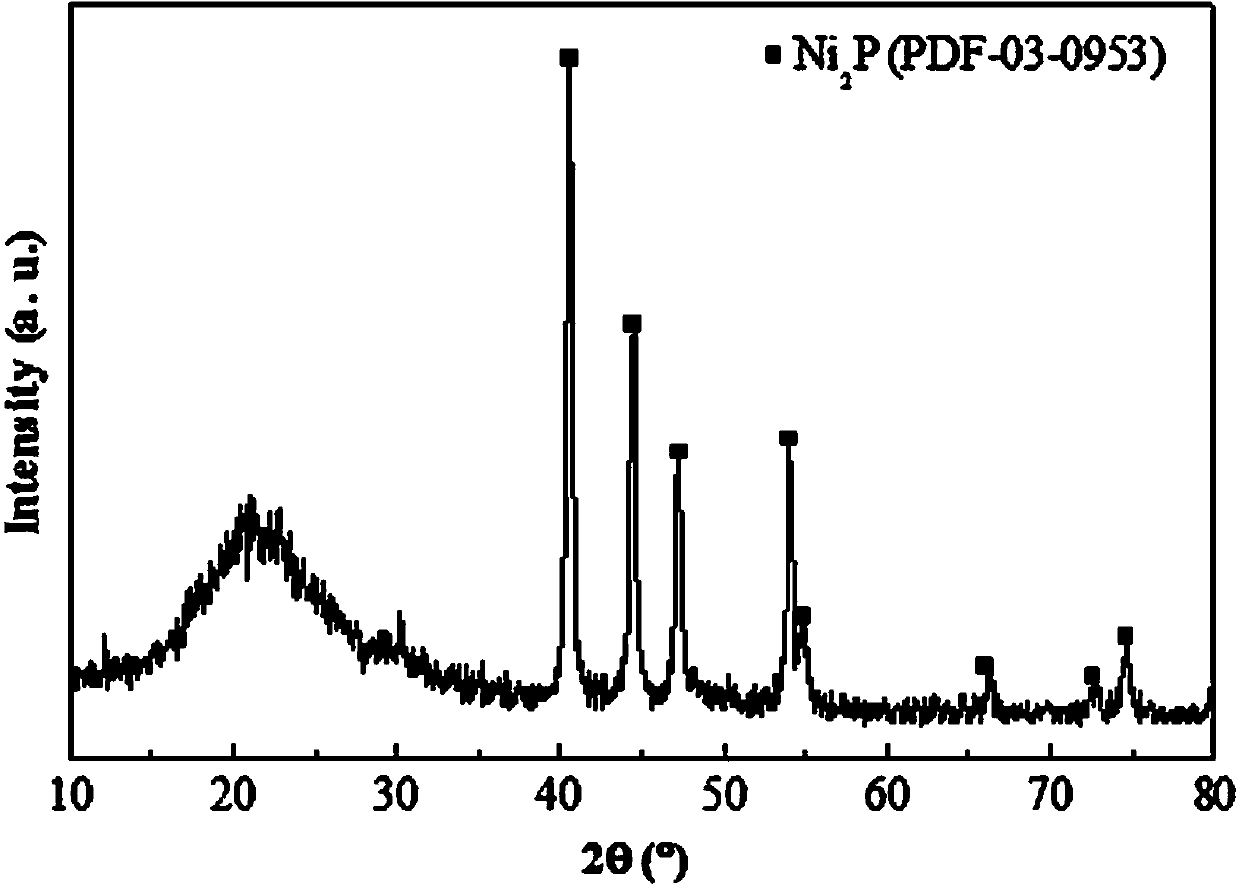

Embodiment 1

[0022] Add nickel acetylacetonate, triphenylphosphine and MCM-41 mesoporous sieve into tri-n-octylamine according to a certain metering ratio, and stir at room temperature until fully mixed. Among them, the mass ratio of nickel acetylacetonate, triphenylphosphine, MCM-41 mesoporous sieve and tri-n-octylamine is 1:2:0.67:32.

[0023] The second step, reaction preparation catalyst:

[0024] Add the slurry obtained in the first step into a stirred reactor at normal pressure, heat it to 330 °C at a rate of 2 °C per minute in a nitrogen flow of 100 mL / min under stirring conditions, and keep the temperature at this temperature for 3 hours. Cool down to room temperature, and finally with 10% (V / V) O 2 / N 2 Mixed gas passivation for 1 hour.

[0025] The third step, filtering, washing and drying:

[0026] The passivated slurry was filtered under reduced pressure with a sand core funnel, and the filter cake after washing was washed at 50°C with a mixed solution of ethanol and carbon...

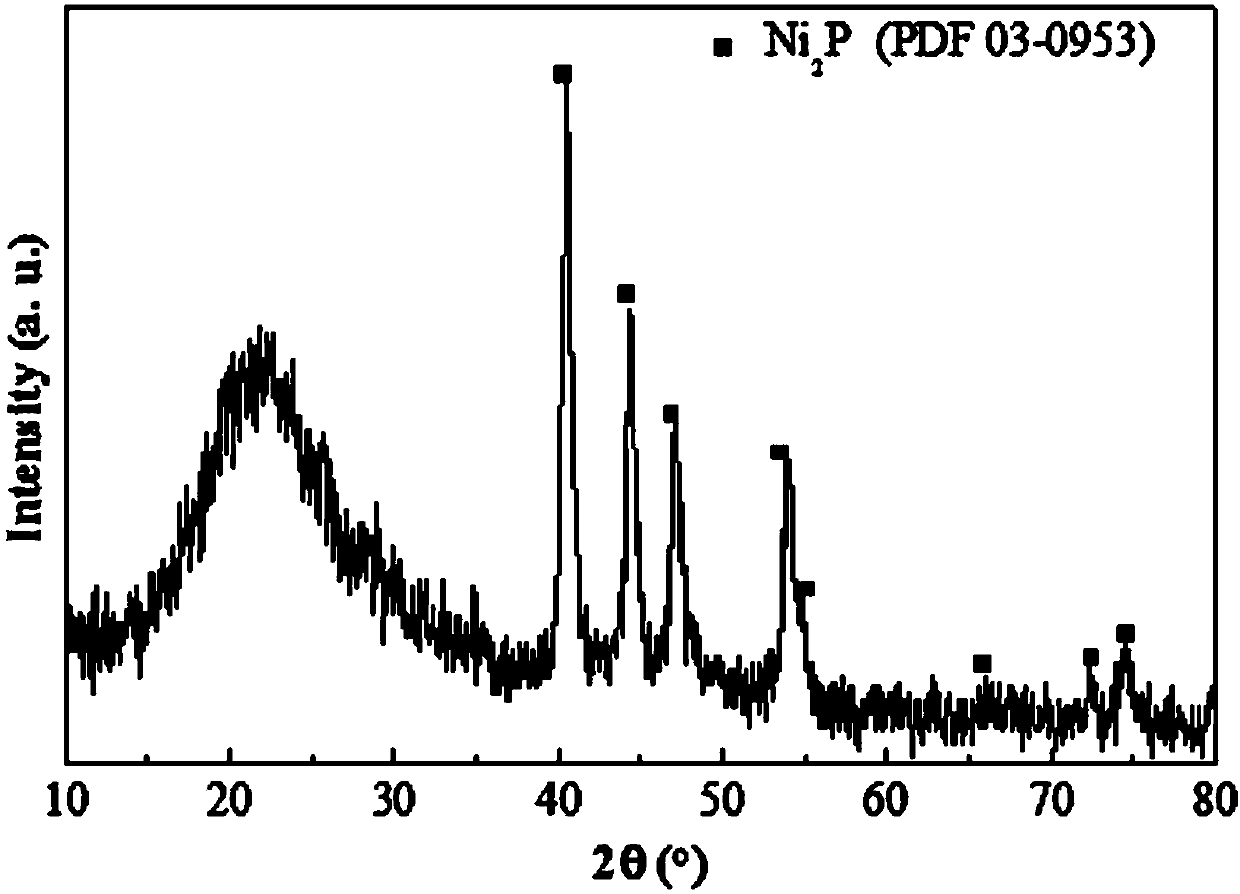

Embodiment 2

[0032] Add nickel acetylacetonate, triphenylphosphine and MCM-41 mesoporous sieve into tri-n-octylamine according to a certain metering ratio, and stir at room temperature until fully mixed. Among them, the mass ratio of nickel acetylacetonate, triphenylphosphine, MCM-41 mesoporous sieve and tri-n-octylamine is 1:6:0.67:32.

[0033] The second step, reaction preparation catalyst:

[0034]Add the slurry obtained in the first step into a stirred reactor at normal pressure, heat it to 330 °C at a rate of 2 °C per minute in a nitrogen flow of 100 mL / min under stirring conditions, and keep the temperature at this temperature for 3 hours. Cool down to room temperature, and finally with 10% (V / V) O 2 / N 2 Mixed gas passivation for 1 hour.

[0035] The third step, filtering, washing and drying:

[0036] The passivated slurry was filtered under reduced pressure with a sand core funnel, and the filter cake after washing was washed at 50°C with a mixed solution of ethanol and carbon ...

Embodiment 3

[0042] Add nickel acetylacetonate, triphenylphosphine and MCM-41 mesoporous sieve into tri-n-octylamine according to a certain metering ratio, and stir at room temperature until fully mixed. Among them, the mass ratio of nickel acetylacetonate, triphenylphosphine, MCM-41 mesoporous sieve and tri-n-octylamine is 1:10:0.67:32.

[0043] The second step, reaction preparation catalyst:

[0044] Add the slurry obtained in the first step into a stirred reactor at normal pressure, heat it to 330 °C at a rate of 2 °C per minute in a nitrogen flow of 100 mL / min under stirring conditions, and keep the temperature at this temperature for 3 hours. Cool down to room temperature, and finally passivate with O2 / N2 gas mixture containing 10% oxygen (V / V) for 1 hour.

[0045] The third step, filtering, washing and drying:

[0046] The passivated slurry was filtered under reduced pressure with a sand core funnel, and the filter cake after washing was washed at 50°C with a mixed solution of etha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com