Preparation method and application of coated organic bentonite

A technology of bentonite and sodium-based bentonite is applied in the field of preparation of organobentonite, and can solve the problems of lack of film coating characteristics, unreported preparation method, lack of heavy metal ion adsorption efficiency, and lack of adsorption capacity, and achieves low cost, convenient operation, Strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

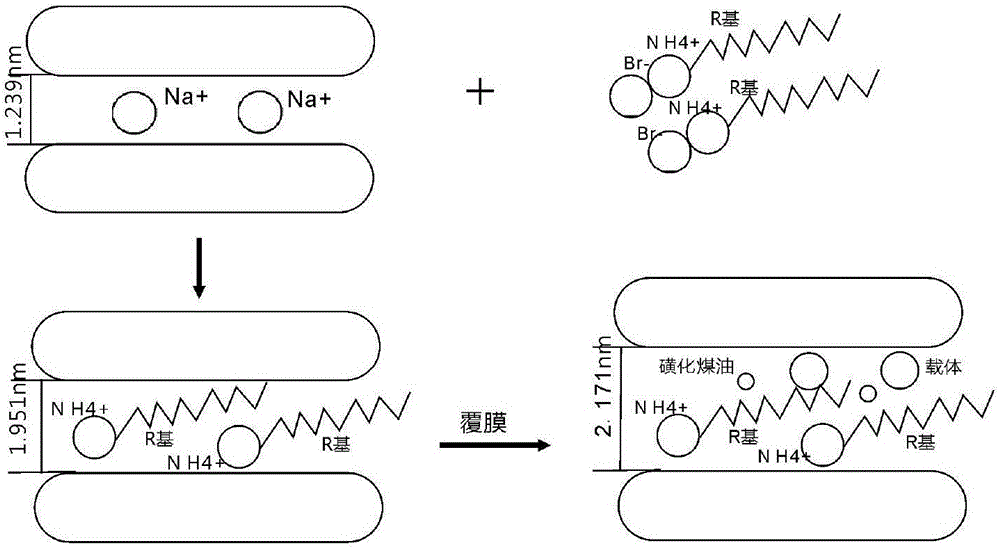

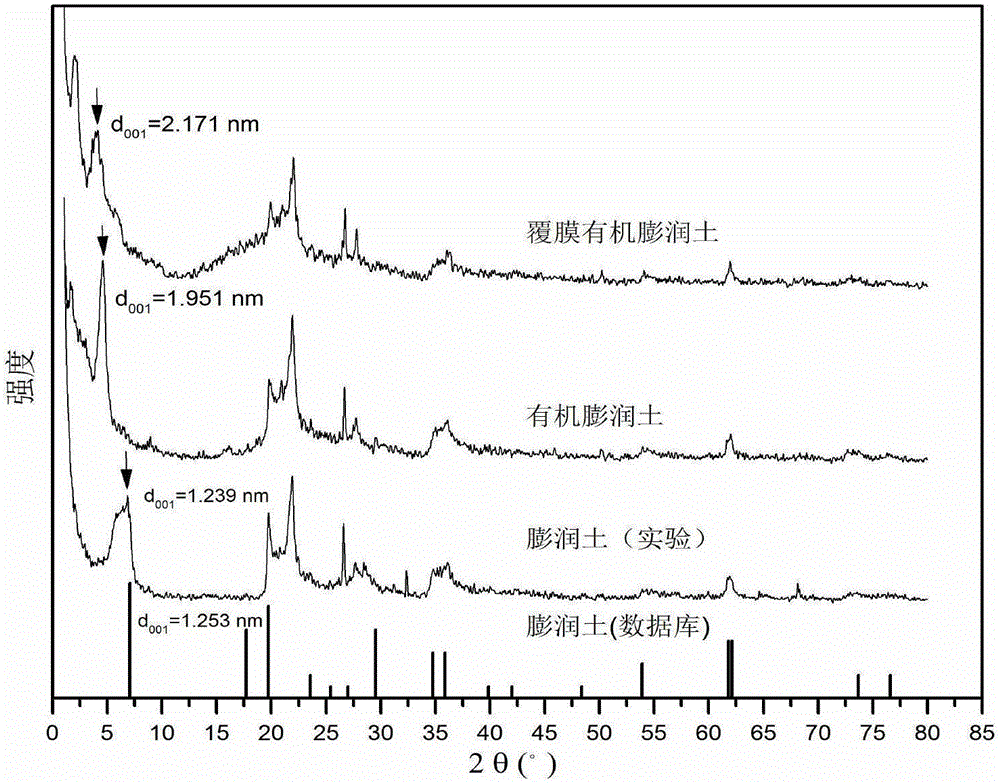

[0035] The preparation method of coated organic bentonite specifically comprises the following steps:

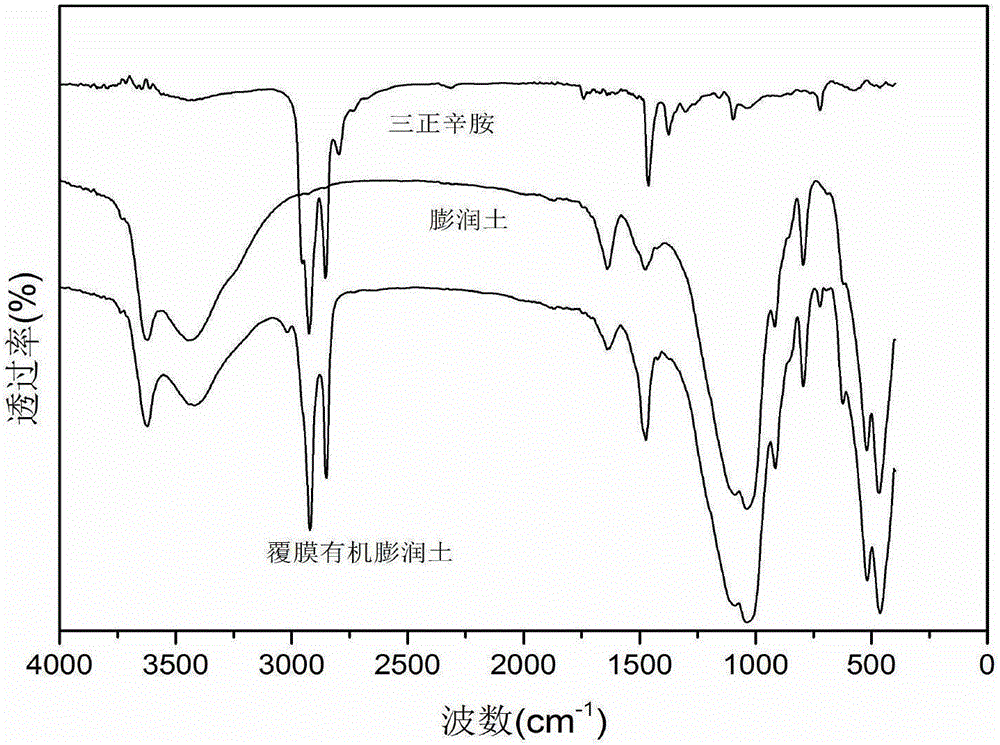

[0036] Mix 30g of cetyltrimethylammonium bromide, 50ml of absolute ethanol, and 450ml of deionized water to obtain mixed solution A; mix 30g of sodium bentonite with 500ml of mixed solution A, and place in a water bath at 60°C Shake for 2 hours, cool to room temperature, centrifuge the product, wash it with 10% ethanol solution and deionized water, and dry it in an oven at 80°C after suction filtration, grind through a 200-mesh sieve, and the solid part is organic Modified bentonite: uniformly mix 2ml of tri-n-octylamine and 10ml of sulfonated kerosene, and shake in a water bath at room temperature for 30 minutes to obtain coating solution B; take 2g of organic bentonite and 12ml of coating solution B to fully absorb, ultrasonically treat for 20min, and age After 10 hours, air-dry after centrifugal separation, and the solid part is coated organic bentonite.

[0037] The res...

Embodiment 2

[0041] The preparation method of coated organic bentonite specifically comprises the following steps:

[0042] Mix 10g of cetyltrimethylammonium bromide, 15ml of absolute ethanol, and 135ml of deionized water to obtain mixed solution A; mix 10g of sodium bentonite with 150ml of mixed solution A, and place in a water bath at 55°C Shake for 3 hours, cool to room temperature, centrifuge the product, wash it with 10% ethanol solution and deionized water, and dry it in an oven at 90°C after suction filtration, grind it through a 200-mesh sieve, and the solid part is organic Modified bentonite: uniformly mix 1ml of tri-n-octylamine and 6ml of sulfonated kerosene, and shake in a water bath at room temperature for 30 minutes to obtain coating solution B; take 1g of organic bentonite and 5ml of coating solution B to fully absorb, ultrasonically treat for 25min, and age After 12 hours, air-dry after centrifugation, and the solid part is coated organic bentonite.

[0043] Get cadmium-co...

Embodiment 3

[0046] In this embodiment, the composition of the coating solution is improved, and two additives are added to achieve better results, which specifically includes the following steps:

[0047] Preparation of film-coated bentonite: Mix 10g of cetyltrimethylammonium bromide, 15ml of absolute ethanol, and 135ml of deionized water to obtain mixed solution A; mix 10g of sodium-based bentonite with 150ml of mixed solution A, Shake in a water bath at 55°C for 3 hours, cool to room temperature and centrifuge the product, wash it once with 10% ethanol solution and deionized water, filter it with suction, dry it in an oven at 90°C, and grind it through a 200-mesh sieve , the solid part is organically modified bentonite; mix 1ml tri-n-octylamine, 0.5mL ethylenediamine, 0.2mL sorbitan monooleate (Span80) and 6ml sulfonated kerosene evenly, shake in a water bath at room temperature After 30 minutes, the coating solution B was obtained; 1g of organic bentonite was fully absorbed with 5ml of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com