A kind of liquid flocculant and preparation method thereof

A flocculant and liquid technology, which is applied in the field of liquid flocculant and its preparation, can solve the problems of difficulty in producing high solid mass fraction, ultra-large molecular weight copolymers, product quality decline, and drying difficulties, and achieve good turbidity removal effect, The effect of low cost and high dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

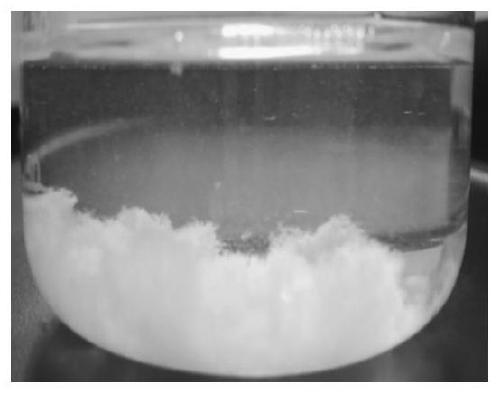

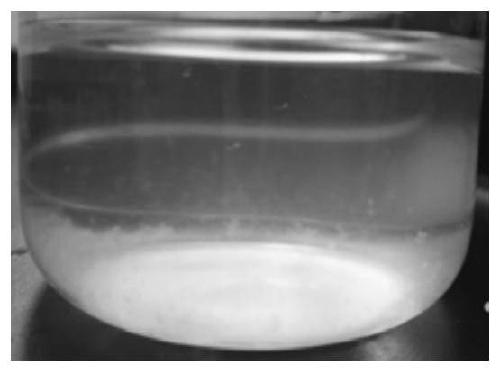

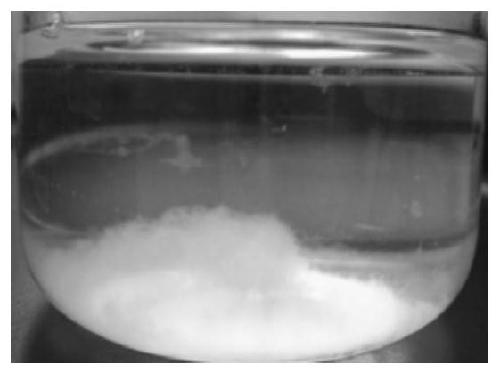

Image

Examples

Embodiment 1

[0031] An embodiment of the preparation method of the liquid flocculant of the present invention, the preparation method includes the following steps:

[0032] (1) Mix acrylamide, quaternary ammonium salt monomer, complexing agent, and co-solvent to obtain a mixture, and then add 40% of the total amount of water to the mixture; (2) At 5°C and under nitrogen, proceed to step (1) Add the first initiator to the resulting mixed solution, add the second initiator after 30 minutes of reaction, and then continue to react for 1 hour at 15°C and in a nitrogen atmosphere; (3) The solution obtained in step (2) is heated to 30°C, and react 5h, add the organic amine monomer, continue the reaction for 1h; (4) Add the crosslinking agent and the remaining water dropwise to the solution obtained in step (3), and control the temperature of the solution between 90°C, and react for 2h to obtain the Liquid flocculant.

[0033] Wherein, in step (1), the molar ratio of quaternary ammonium salt monomer t...

Embodiment 2

[0036] An embodiment of the preparation method of the liquid flocculant of the present invention, the preparation method includes the following steps:

[0037] (1) Mix acrylamide, quaternary ammonium salt monomer, complexing agent, and co-solvent to obtain a mixture, and then add 45% of the total amount of water to the mixture; (2) At 7° C. and in an inert gas atmosphere, go to step ( 1) Add the first initiator to the resulting mixed solution, add the second initiator after 25 minutes of reaction, and then continue the reaction for 2 hours at 12°C and in a nitrogen atmosphere; (3) Heat the solution obtained in step (2) to 35°C , React for 4h, add organic amine monomer, continue to react for 1.2h; (4) Add crosslinking agent and remaining water dropwise to the solution obtained in step (3), and control the temperature of the solution at 82°C, react for 4h, The liquid flocculant is obtained.

[0038] Wherein, in step (1), the molar ratio of quaternary ammonium salt monomer to acrylam...

Embodiment 3

[0040] An embodiment of the preparation method of the liquid flocculant of the present invention, the preparation method includes the following steps:

[0041] (1) Mix acrylamide, quaternary ammonium salt monomer, complexing agent, and co-solvent to obtain a mixture, and then add 50% of the total amount of water to the mixture; (2) At 10°C and in nitrogen, proceed to step (1) Add the first initiator to the resulting mixed solution, add the second initiator after 20 minutes of reaction, and then continue to react for 3 hours at 10°C and in a nitrogen atmosphere; (3) The solution obtained in step (2) is heated to 40°C, and react 3h, add organic amine monomer, continue the reaction for 1.5h; (4) Add the crosslinking agent and the remaining water dropwise to the solution obtained in step (3), and control the temperature of the solution at 75℃, and react for 6h to obtain the The liquid flocculant.

[0042] Wherein, in step (1), the molar ratio of quaternary ammonium salt monomer to acr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com