Liquid supply device and liquid supply method for sanitary foam applicator of closestool

A liquid supply and foam technology, which is applied to sanitary equipment, water supply devices, buildings and other directions for toilets, can solve the problems of promotion restrictions and inconvenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

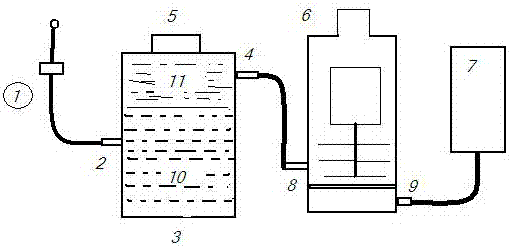

[0009] Embodiment 1: After removing the liquid injection hole 5 hole plug and filling the foaming agent 10, the container 3 is filled with water, and then the liquid injection hole is plugged, the foaming agent is quickly dissolved in water to form a foaming liquid, and the power switch is turned on , the air pump 7 provides compressed gas to the air inlet 9 of the foam generating device 6, and the water pump extracts the foaming liquid from the liquid outlet hole 4 of the container to the water inlet 8 of the foam generating device, and the compressed gas and the foaming liquid are in the mechanical process of the foam generating device The fine foam is produced under action, and enters the toilet sink through the pipe. When the water pump draws the foaming liquid from the liquid outlet hole of the container, a negative pressure will be generated in the closed container at this time, and the water in the toilet tank 1 will be sucked into the container from the water inlet 2 du...

Embodiment 2

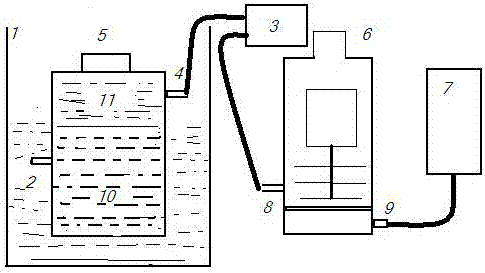

[0010] Embodiment 2: After removing the liquid injection hole 5 hole plug and filling the foaming agent 10, the container is closed 3 and filled with water, and then the liquid injection hole is plugged, the foaming agent is quickly dissolved in water to form a foaming liquid, and the power is turned on , the water pipe switch 1 is turned on, tap water enters the closed container from the water inlet hole 2 under pressure, and the foaming liquid is squeezed out from the liquid outlet hole 4 and enters the foaming device 6 through the pipe and water inlet 8, and the water pipe switch can be installed with electric control to start The device and the device for adjusting the water flow control the flow rate of the foaming liquid into the foaming device. The air pump 7 provides compressed gas to the foaming device. The compressed gas and foaming liquid produce fine foam under the mechanical action of the foam generating device, and enter the toilet sink through the pipeline. . Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com