Practical sterilization device

A sterilizing device and practical technology, applied in the field of sterilizing, can solve the problems of easy irradiation on the human body, difficult to adjust the orientation, and difficult sterilizing effect, so as to prevent the leakage of ultraviolet rays and improve the safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

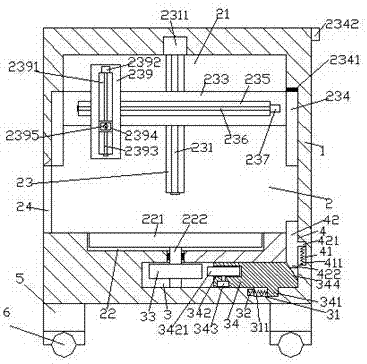

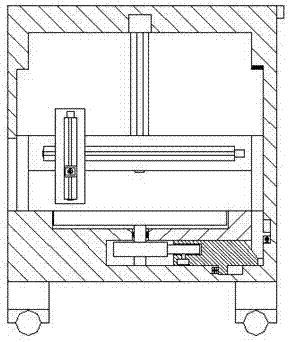

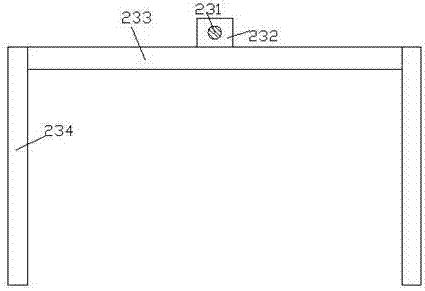

[0021] Such as Figure 1-Figure 5 As shown, a practical sterilizing device of the present invention includes a box body 1 with a cavity 2 inside, the top wall of the cavity 2 is provided with a first assembly cavity 21, and the bottom wall of the cavity 2 is provided with The second assembly cavity 22, the box body 1 at the bottom of the second assembly cavity 22 is provided with a control cavity 3 extending to the right, and the tail end of the extension section on the right side of the control cavity 3 is provided with an upward extension And pass through the perforation 4 of the inner bottom wall of the box body 1, the inner wall of the rear side of the cavity 2 is provided with a first sliding groove 23 extending upward and entering the first assembly cavity 21, the first sliding groove 23 A first screw rod 231 is arranged in the transfer groove 23, and the first screw rod 231 is connected with a first motor 2311, and the first motor 2311 is arranged in the inner top wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com