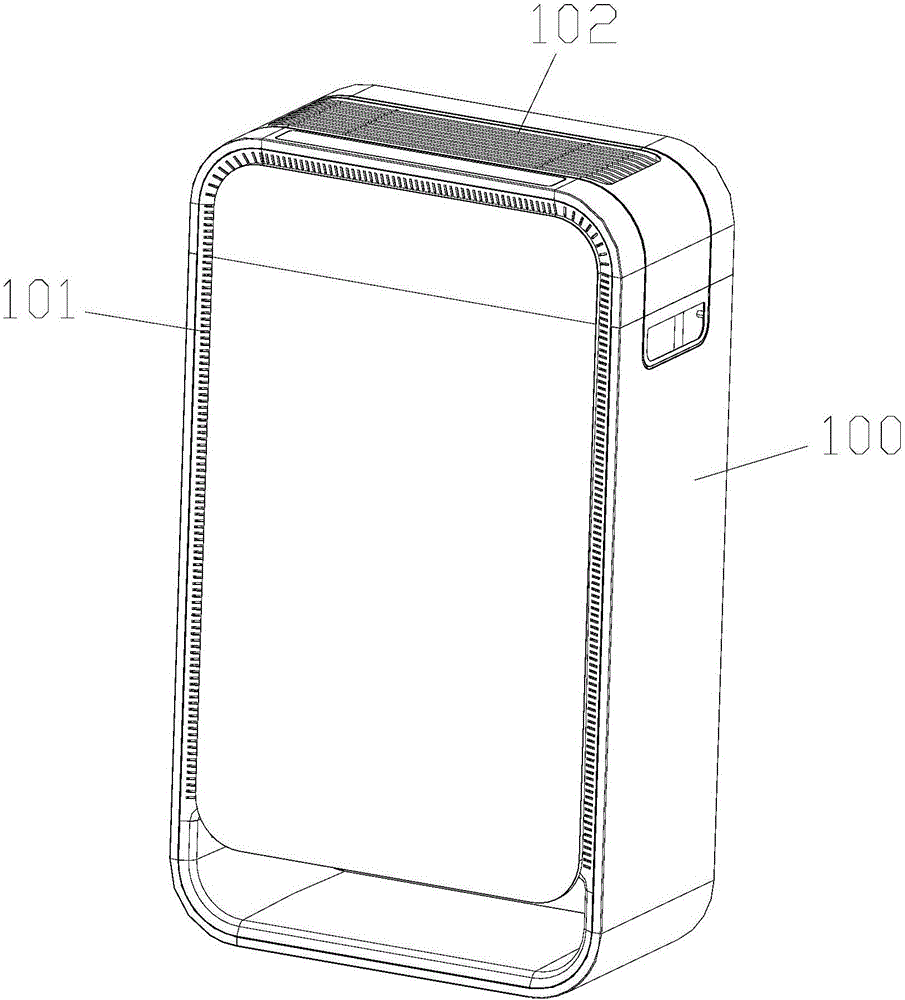

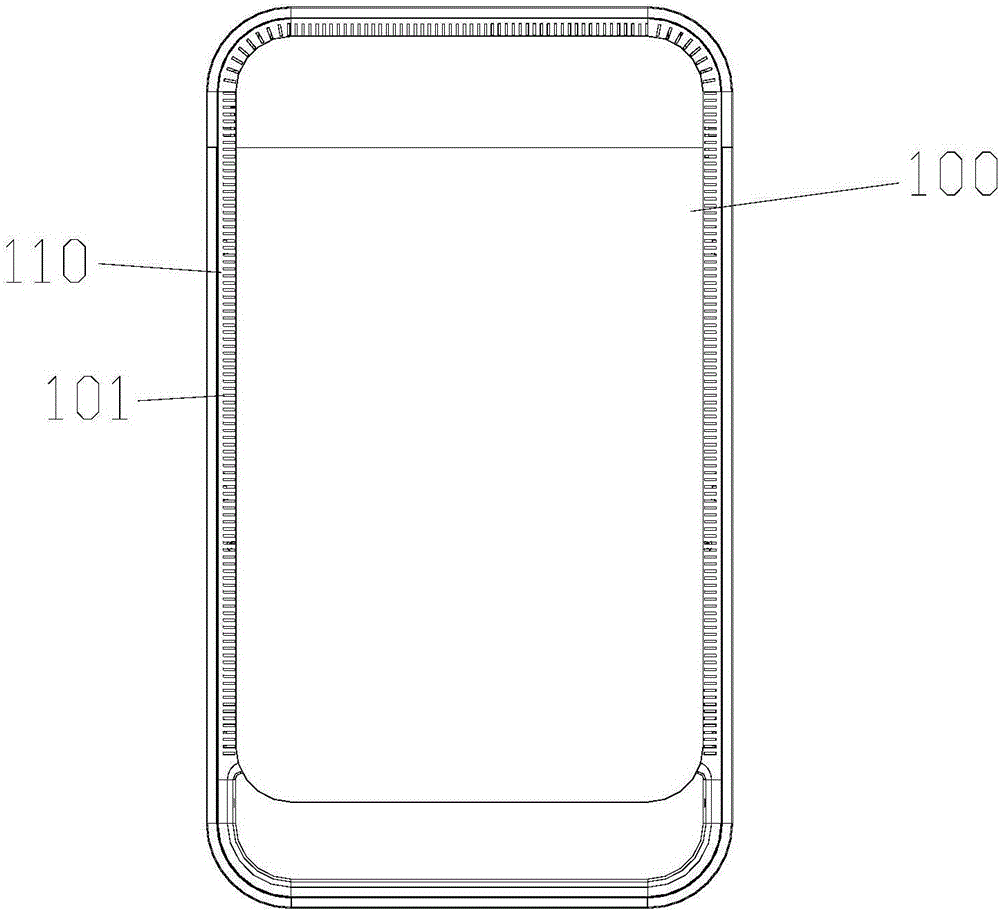

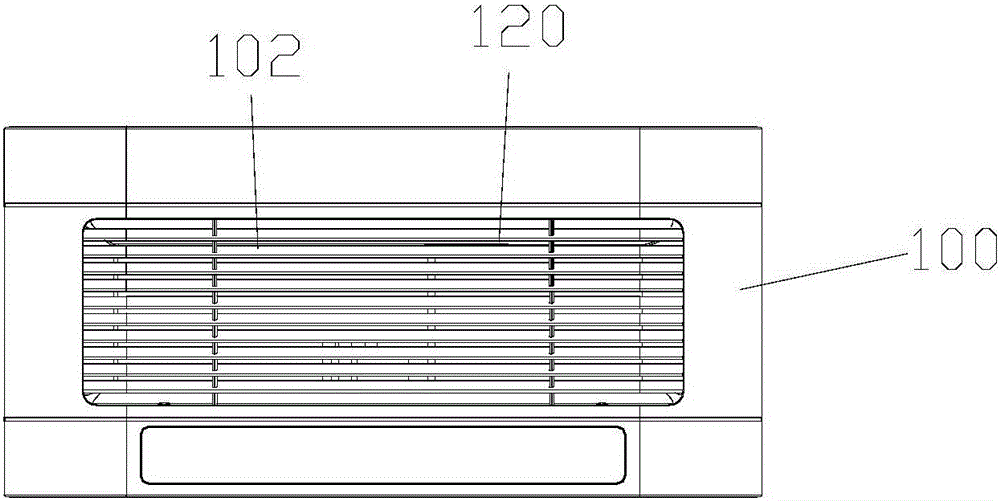

Nanometer platinum net material, preparing method of nanometer platinum net material and air purifier

An air purifier and nano-platinum technology, applied in the field of machinery, can solve problems such as ultraviolet leakage, and achieve the effect of protecting human health and avoiding ultraviolet leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The first step is to dissolve 95.0% pure platinum in aqua regia to obtain chloroplatinic acid (H2PtCl6·6H2O, red to brown-red solid), dissolve solid chloroplatinic acid in water, and then add 2.0% number average to the net chloroplatinic acid aqueous solution Polyvinyl alcohol with a molecular weight of 5000, stir for 10 minutes and then stand by; the second step is to soak the glass fiber mesh with a thickness of 1.0mm in the water in the stainless steel reactor, and then make the water temperature and pressure exceed the critical point (critical temperature T = 374 ℃, critical pressure P=22.1MPa) is supercritical water. Supercritical water has very good oxidizing properties. It can oxidize / etch many chemical functional groups and microscopic protrusions on the surface of glass fiber (this makes the first The solution is easier to "bond" on the surface of the glass fiber mesh); in the third step, the treated glass fiber mesh is soaked in the solution of the first step fo...

Embodiment 2

[0050] The first step of the present invention is to dissolve platinum with a purity of 96.0% in aqua regia to obtain chloroplatinic acid (H2PtCl6·6H2O, red to brown-red solid), dissolve solid chloroplatinic acid in water, and then add 3.0 to the chloroplatinic acid aqueous solution. % Polyvinyl alcohol with a number average molecular weight of 5000, stir for 15 minutes and then stand by; the second step is to soak the 2.0-thick glass fiber mesh in the water in the stainless steel reactor, and then make the water temperature and pressure exceed the critical point (critical temperature T =374℃, critical pressure P=22.1MPa), supercritical water will become supercritical water. Supercritical water has very good oxidizing properties and can oxidize / etch many chemical functional groups and microscopic protrusions on the surface of glass fiber (which makes The solution in the first step is easier to "bond" on the surface of the glass fiber mesh); in the third step, the treated glass f...

Embodiment 3

[0053] The first step of the present invention is to dissolve platinum with a purity of 97.0% in aqua regia to obtain chloroplatinic acid (H2PtCl6·6H2O, red to brown-red solid), dissolve solid chloroplatinic acid in water, and then add 4.0 to the chloroplatinic acid aqueous solution. % Polyvinyl alcohol with a number average molecular weight of 5000, stir for 20 minutes and then stand by; the second step is to soak the 3.0mm glass fiber mesh in the water in the stainless steel reactor, and then make the water temperature and pressure exceed the critical point (critical temperature After T=374℃, critical pressure P=22.1MPa), supercritical water will become supercritical water. Supercritical water has very good oxidizing properties and can oxidize / etch many chemical functional groups and microscopic protrusions on the surface of glass fiber (this Make it easier for the solution in the first step to "bond" on the surface of the glass fiber mesh); in the third step, the treated glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com