A strip production system and method

A production system and strip steel technology, applied in the direction of surface pretreatment, device for coating liquid on the surface, coating, etc., can solve the problems of poor stability, high free chromium content, increase production cost, etc., to improve uniformity, The effect of reducing production costs and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

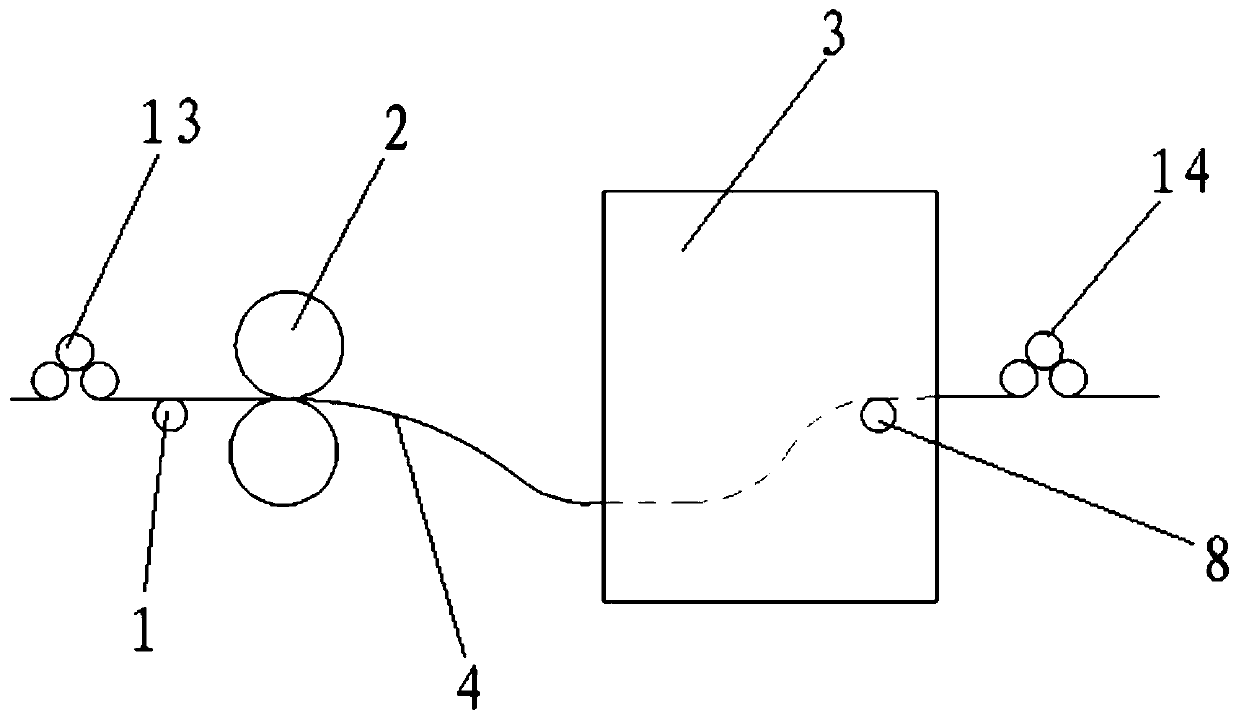

[0032] The embodiment of the present invention reduces the content of free chromium in the product by providing a strip steel production system and method.

[0033] The technical solution in the embodiment of the present invention is to solve the above problem, and the general idea is as follows:

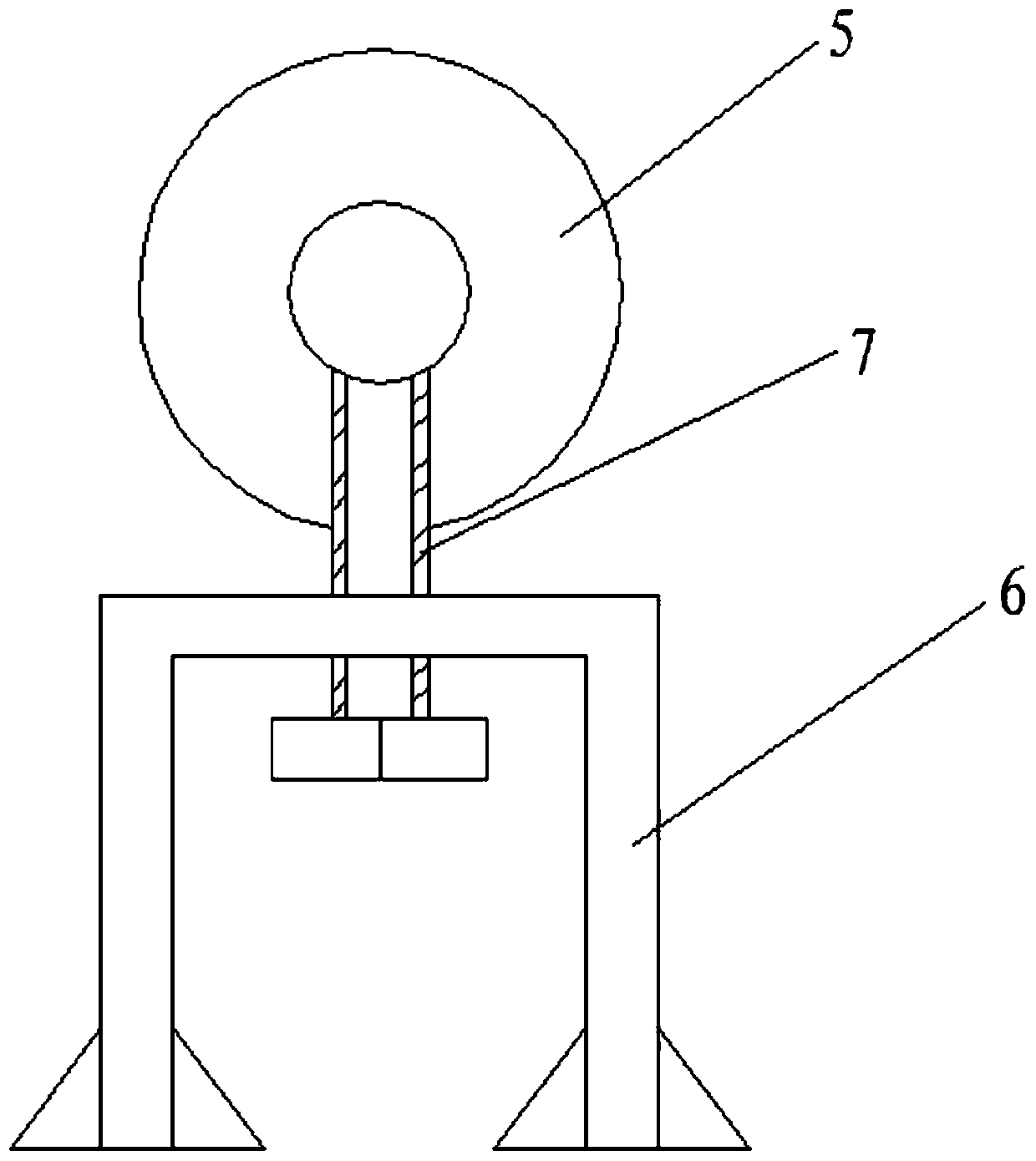

[0034] Adjust the height of the strip by setting the strip height adjustment equipment to achieve the purpose of adjusting the thickness of the strip surface coating, that is, if the coating on the upper surface of the strip is thicker, reduce the height of the strip; Thicker coating increases the height of the strip, thereby improving the uniformity of the coating thickness in the longitudinal direction of the strip; on the one hand, it not only reduces the content of free chromium, but also reduces from 2000ppm to less than 100ppm, thus achieving an environmentally friendly And it can also avoid the reduction of revenue caused by downgraded products (the price of downgraded produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com