Positioning mechanism switching device and assembly line

A switching device and positioning mechanism technology, applied in auxiliary devices, motor vehicles, transportation and packaging, etc., can solve problems such as lifting and unfavorable automation efficiency, and achieve the effect of convenient switching and convenient function switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

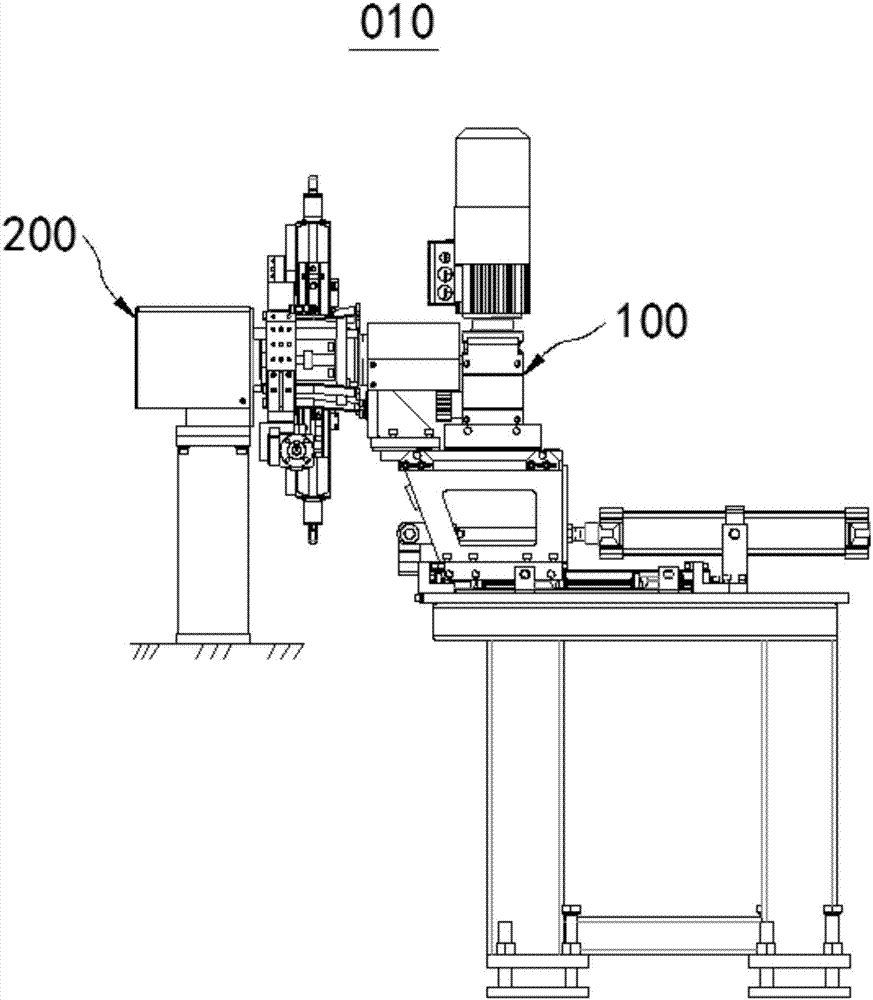

[0047] figure 1 It is a structural schematic diagram of the positioning mechanism switching device 010 in Embodiment 1 of the present invention. Please refer to figure 1 , the positioning mechanism switching device 010 in this embodiment includes a switching device 100 and a positioning device 200 .

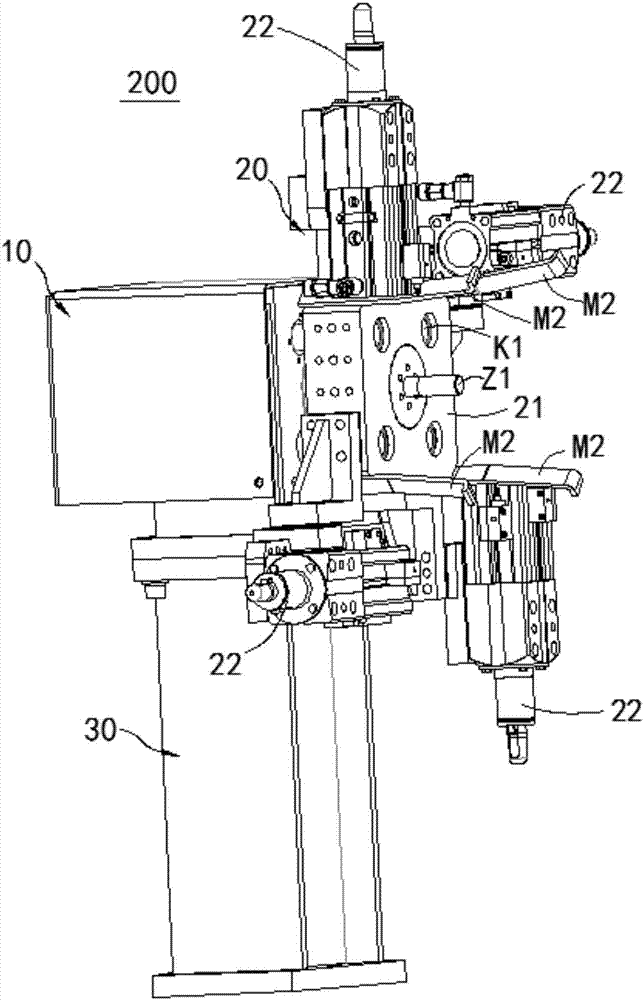

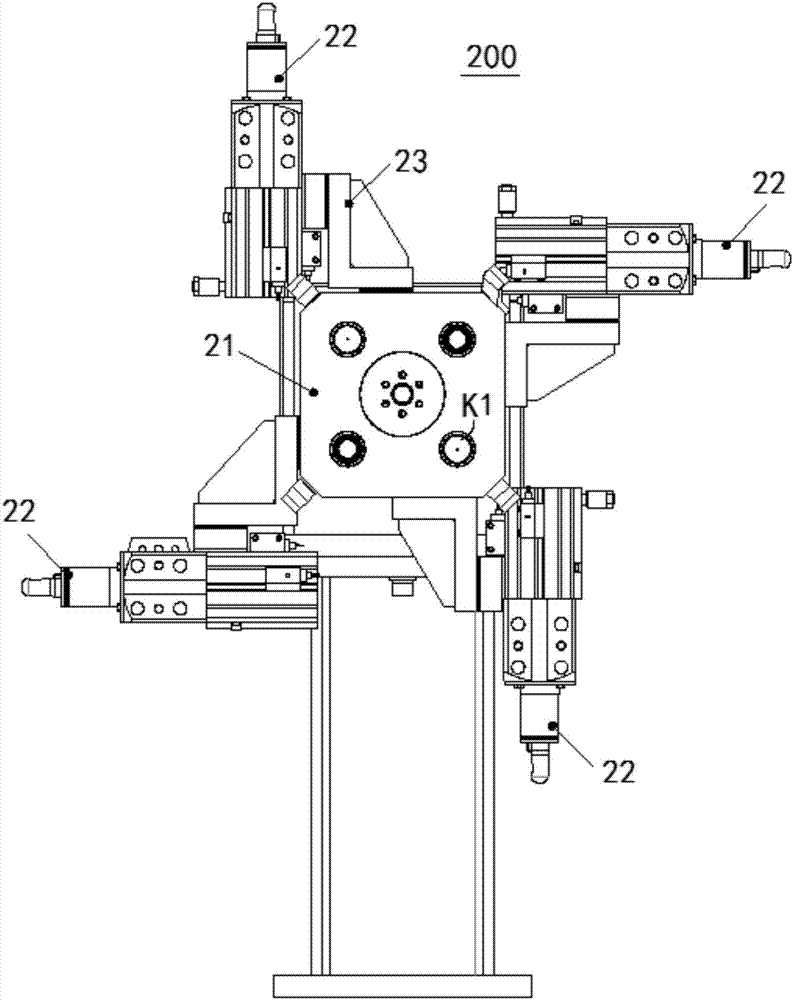

[0048] figure 2 , image 3 , Figure 4 The positioning device 200 in this embodiment is shown at different angles. See figure 2 (for coordination see image 3 , Figure 4), the positioning device 200 includes a fixed seat 10, a positioning plate 20, and a base 30. The fixing base 10 is installed on the upper end of the base 30 , and the positioning plate 20 is rotatably connected to the side of the fixing base 10 . During normal use, the rotation between the positioning disc 20 and the fixed seat 10 is locked and limited, and the rotation restriction between the positioning disc 20 and the fixed seat 10 can be unlocked when necessary. The specific structure and method ...

Embodiment 2

[0069] See Figure 11 , Figure 12 , the embodiment of the present invention provides an assembly line 001, which includes a transmission line 300 and at least one positioning mechanism switching device 010 in the first embodiment. The positioning device 200 of the positioning mechanism switching device 010 is disposed on the transmission line 300 , and the switching device 100 is opposite to the positioning device 200 .

[0070] By setting the positioning mechanism switching device 010 in the first embodiment on the transmission line 300, the automatic switching of the positioner 22 of some processes (such as welding, etc.) on the assembly line 001 can be realized, so that the assembly line 001 can automatically adapt to different to-be-assembled Fittings, assembly in different assembly positions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com