A Planetary Polishing Device Containing Double Parallelogram Mechanism

A quadrilateral mechanism and polishing device technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, and surface polishing machine tools, etc., can solve the problems of large mass and complex mechanical structure of the revolution transmission mechanism, and achieve small inertial force, Simple mechanical structure, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The planetary polishing device of the present invention will be further described in detail below with reference to the embodiments and the accompanying drawings.

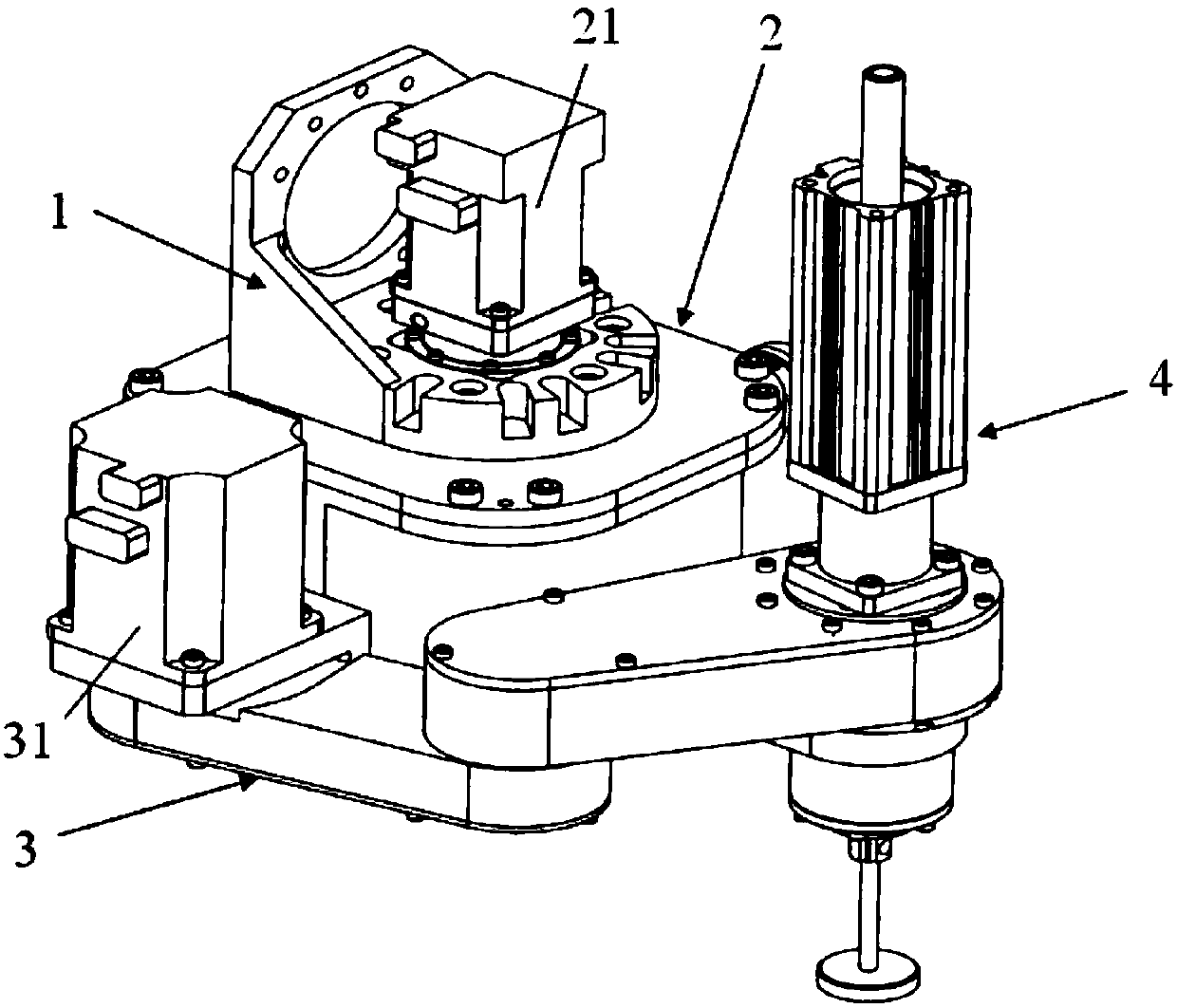

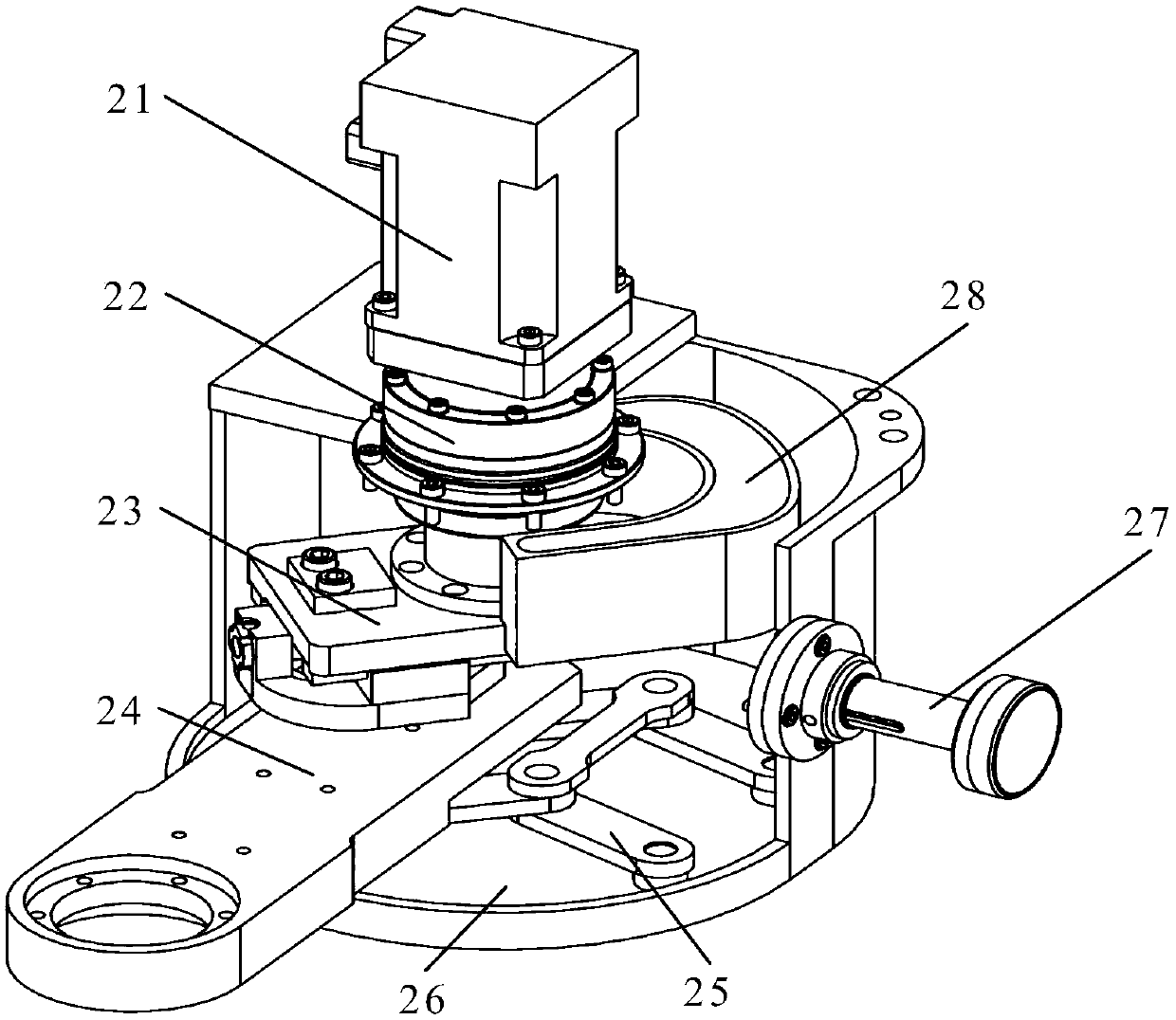

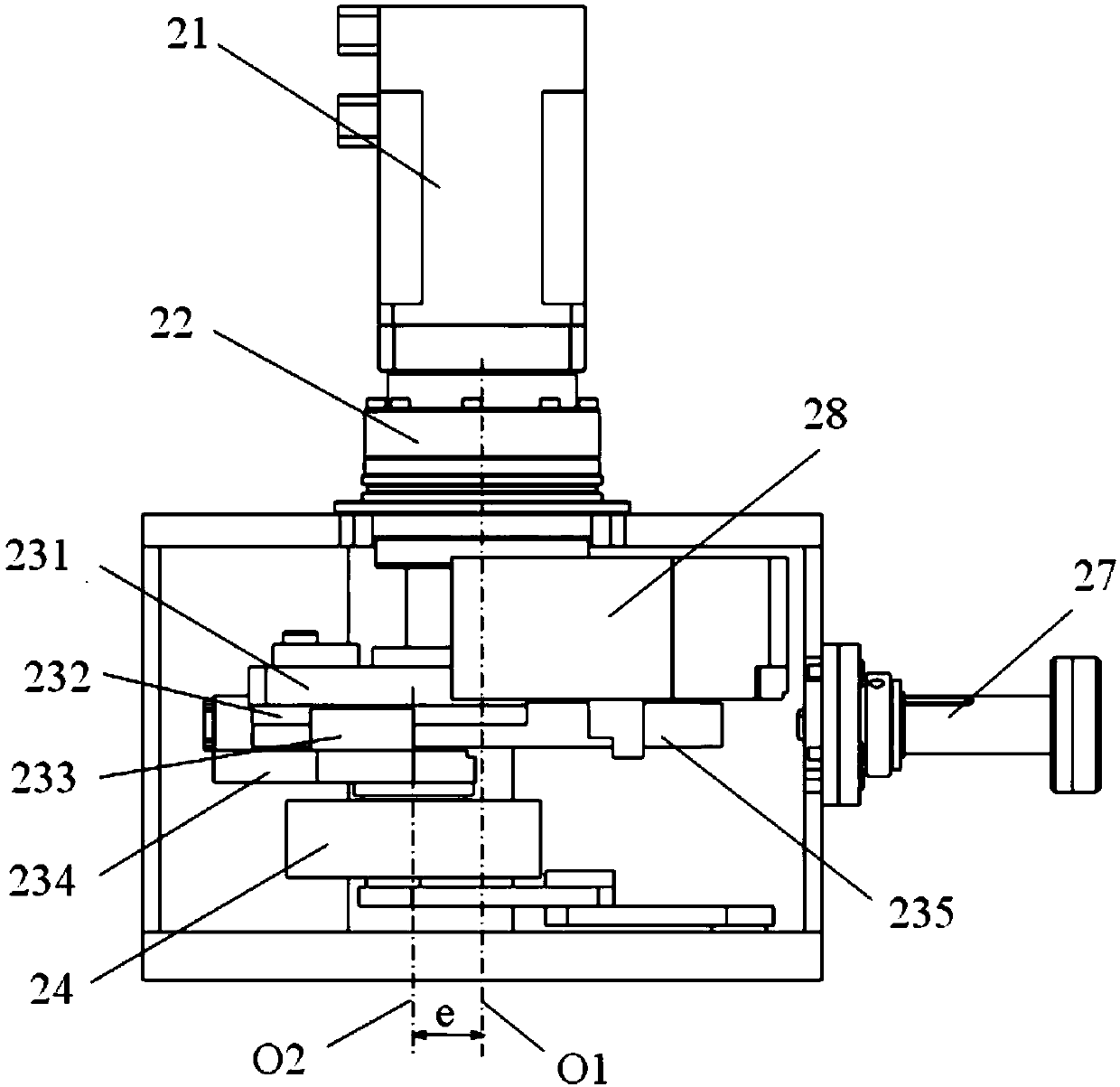

[0032] like Figure 1 to Figure 5 As shown, a planetary polishing device with a double parallelogram mechanism includes a mounting flange 1, a revolution transmission part 2, an autorotation transmission part 3, and a polishing shaft 4; the revolution transmission part 2 includes: a revolution motor 21, a reducer 22, an eccentric Adjustment assembly 23, polishing shaft installation connecting rod 24, double parallelogram mechanism 25, housing 26, eccentric adjustment knob 27 and balance weight 28; revolution motor 21 is connected with reducer 22 input shaft, and the output shaft of reducer 22 is adjusted with eccentricity The assembly 23 is consolidated, and the revolution motor 21 drives the eccentric adjustment assembly 23 to rotate around the rotation axis O1; the eccentric adjustment assembly 23 is rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com