Vehicle upper swing arm assembly

A technology for automobiles and assemblies, which is applied in the direction of the cantilever mounted on the pivot, vehicle parts, suspension, etc. It can solve the problems that the load transmission of the mandrel shaft does not meet the requirements, the supporting effect is not enough, and it is not easy to produce and practice, so as to achieve safety Guarantee of stability and stability, strengthen the support effect, increase the effect of elastic potential energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

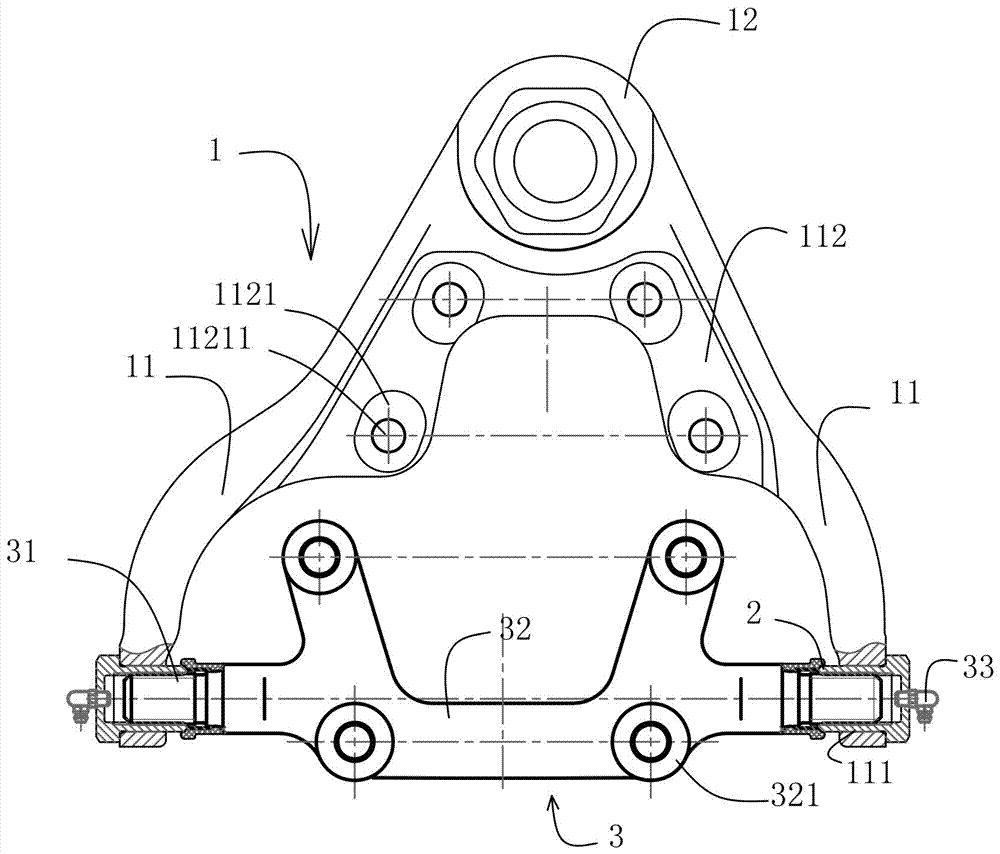

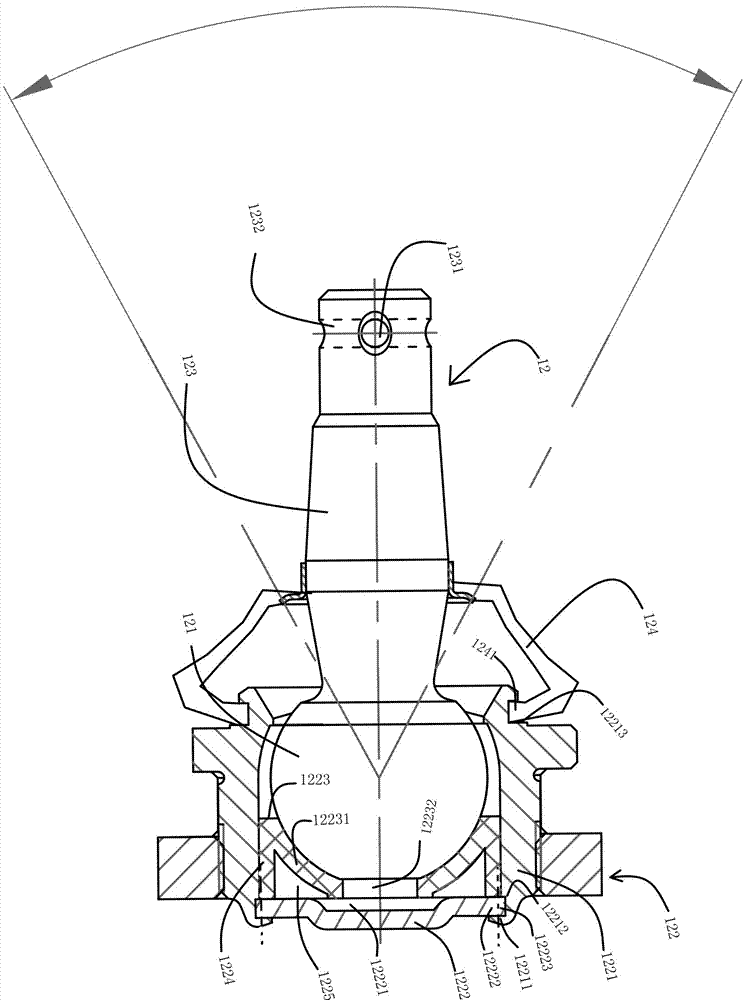

[0029] Such as Figure 1 to 2 The illustrated upper swing arm assembly of an automobile includes a swing arm main body 1. The swing arm main body 1 includes two arm bodies 11 connected in a "herringbone" shape at one end and a ball pin 12. The ball pin 12 The ball head pin 12 includes a ball head 121, a ball head seat 122, and a ball head rod 123 connected to the ball head 121. The ball head 121 is mounted on the ball In the head base 122; the other end of the arm body 11 is provided with a circular through hole 111, the direction of the circular through hole 111 is perpendicular to the direction of the ball pin 12, and the circular through hole 111 is provided There is a bushing 2, and a special-shaped shaft 3 capable of rotating in the bushing 2 is provided in the bushing 2. The ball head seat 122 includes a ball head outer seat 1221, a sealing plate 1222, and a ball head abutment seat 1223. The ball head outer seat 1221 has an upper opening and a lower opening. The end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com