Metro depot reserved stand column inspection pit rail construction method

A technology for subway depots and construction methods, which is applied in the field of track construction of reserved column inspection pits in subway depots, and can solve the problems of inability to meet the construction accuracy requirements of reserved column inspection pits, large errors of reserved columns, and unguaranteed quality and other problems, to achieve the effect of saving the cost of engineering measures, easy to operate, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

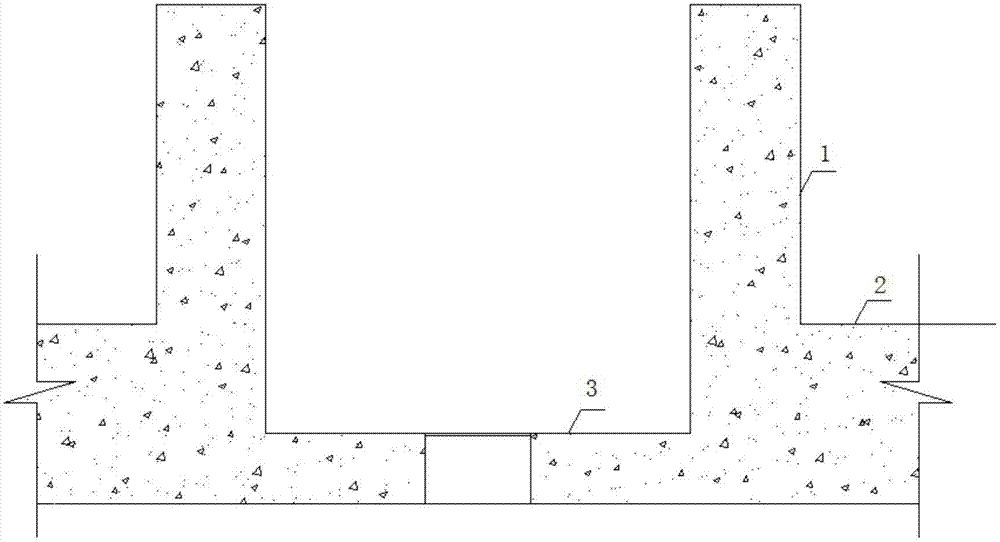

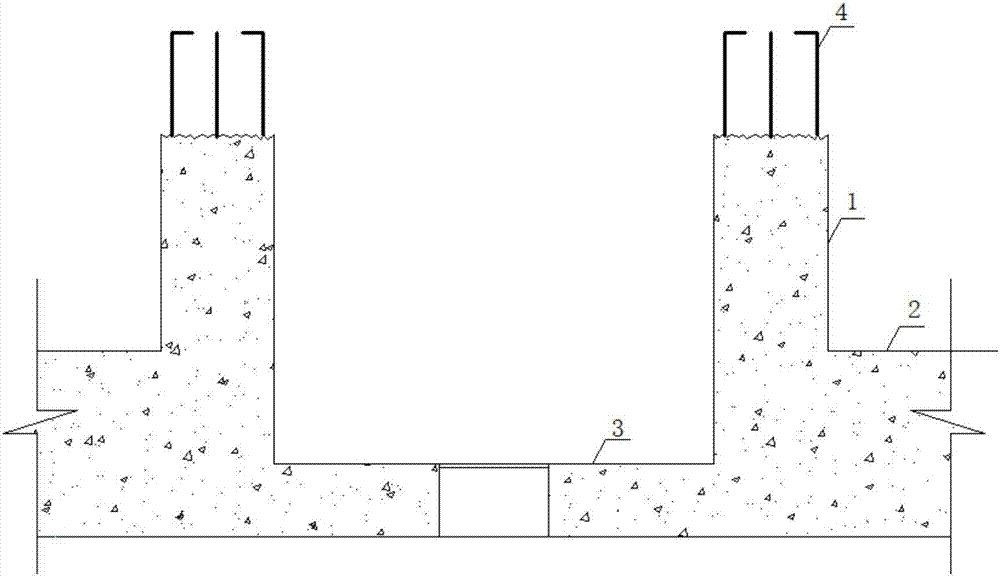

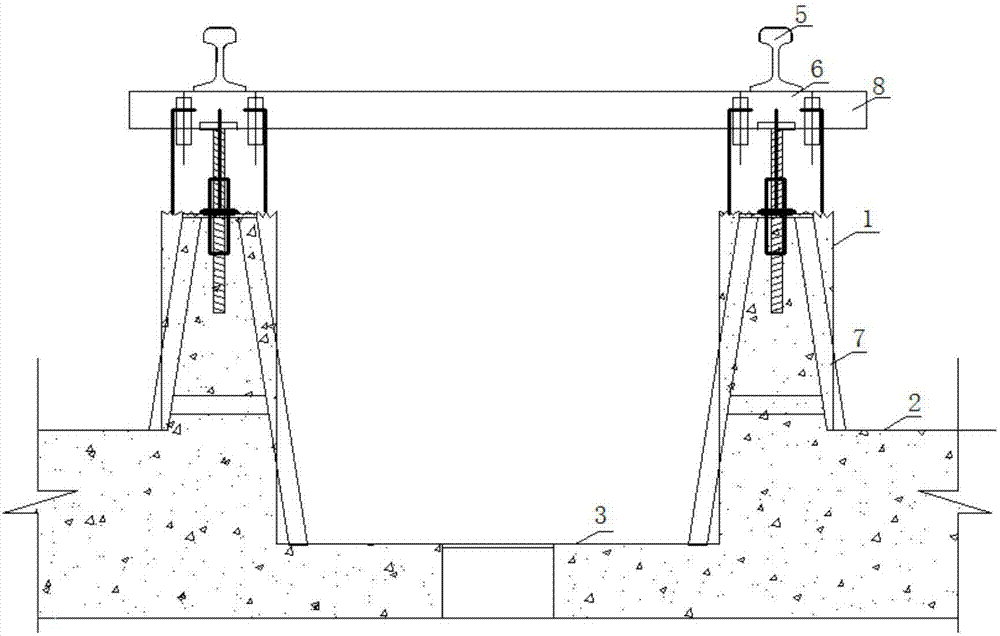

[0033] The invention relates to a track construction method for inspection pits reserved for uprights in subway depots. The reserved uprights are chiseled to remove the concrete above the uprights 500 mm below the rail surface, and the rails are fixed on the uprights by using a rail fixed support bracket and a symmetrical cable-stayed device. According to the design requirements, install fasteners and carry out rail row assembly and rail connection. Use rail fixing devices to adjust the rail bottom slope, gauge, direction, level, and elevation. After the formwork is fixed step by step, the reserved column concrete is poured. The cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com