Comb-tooth friction clamping drum-type saffron threads picking head

A drum type, picking head technology, applied in the direction of picking machines, agricultural machinery and implements, applications, etc., can solve the problems of safflower broken, falling, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

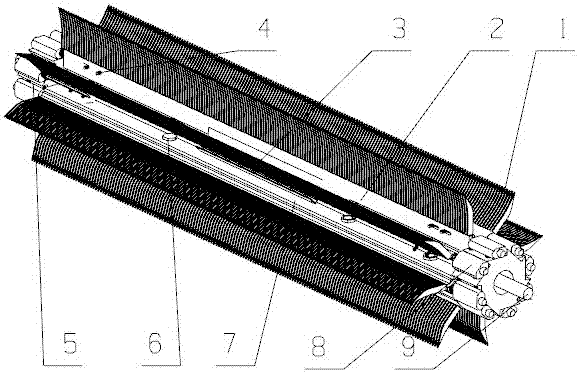

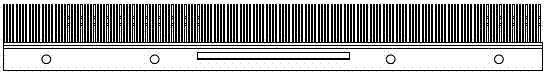

[0024] The invention relates to a drum-type safflower picking head with comb-tooth friction clamping. When the safflower harvesting machine is working, the power shaft of the picking head is connected with a frame, so as to realize the rotation of the rotating main shaft 7 of the picking head. When the rotating spindle rotates at 1400 r / min, the frame drives the picking head forward. When the picking head touches the safflower stem or pedicel, the stalk or pedicel will be pushed by the picking head to avoid it by itself. When the picking head touches the filigree, the tooth end will pick up the filigree and comb it, and the push-pull electromagnet 8 will move to realize the movement of the push-pull rod. The comb tooth 1 reciprocates linearly on the slide rail 3, that is, after the power is turned on, the movable comb tooth 2 moves 2 mm to reach the clamping position to realize the clamping of the filament, and the rotating spindle 7 rotates to realize the extraction of the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com