High-temperature dust remover

A high-temperature dust collector and dust collection technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of high installation and protection costs, failure to clean the filter material layer, and reduction of filter area, etc. Achieve the effect of improving safety, huge economic value and reducing the pressure of dust removal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

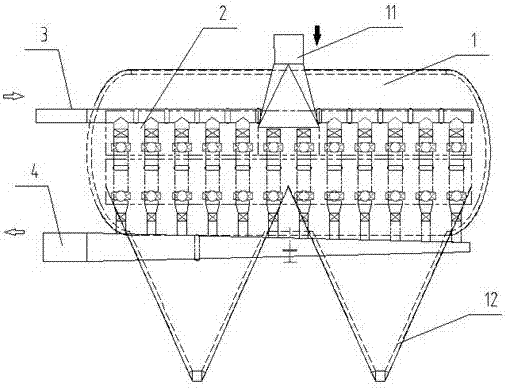

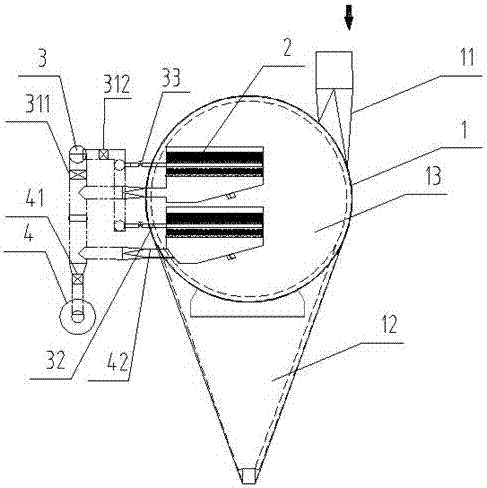

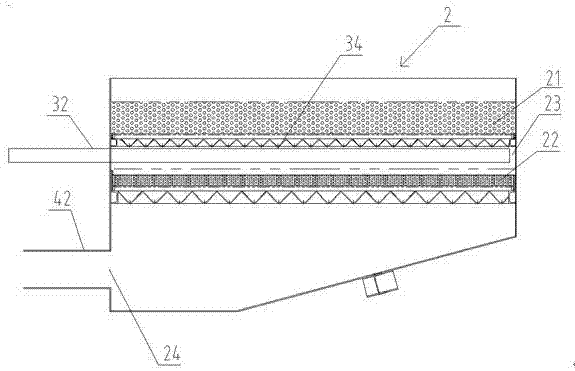

[0023] Such as Figure 1-3 As shown, a high-temperature dust collector includes a horizontal housing 1, several filter unit groups arranged in the housing 1, and an air induction manifold 4 and an anti-blow pipe 3 arranged outside the housing. The filter unit group is arranged along the lateral direction of the casing 1, and the filter unit group includes several filter units 2 arranged along the longitudinal direction of the casing. The casing 1 is provided with an air inlet 11, and the inside of the casing 1 is provided with a dust collection channel 13. The bottom of the casing 1 is provided with several dust outlets 12 along the transverse direction, the bottom of the filter unit 2 is provided with an air outlet 24, and the air outlet 24 is connected with a comprehensive air duct 42, and the reverse blowing duct 3 and the air guide The air confluence pipes 4 are all connected to the integrated air duct 42 and connected to the air outlet 24 through the integrated air duct 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com