Stainless steel composite tile and manufacturing process thereof

A technology of stainless steel and stainless steel plate, which is applied in the direction of building structure, roof, and roof using flat/curved panels, etc. It can solve the problems of low strength, short life, and high cost of composite tiles, and achieve high strength, long life, and low manufacturing cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

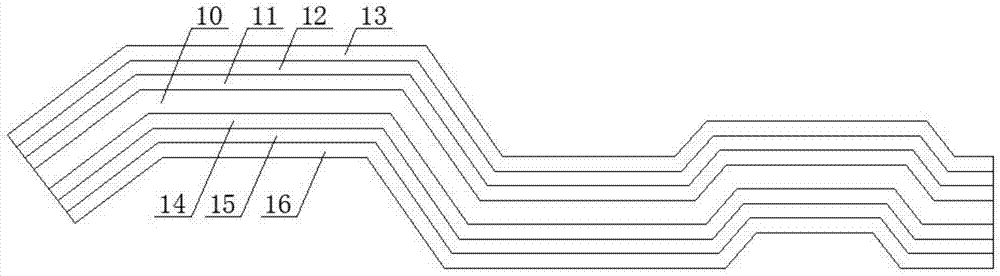

[0025] Stainless steel composite tiles, such as figure 1 As shown, it includes a plastic plate 10 that is integrally injection-molded into a bent shape. The plastic plate 10 is a polyvinyl chloride plate. The upper surface of the plastic plate 10 is sequentially provided with a first composite adhesive layer 11 and a first stainless steel plate 12. The shape of the first stainless steel plate 12 is the same as that of the plastic plate 10, and the first composite adhesive layer 11 fixes the first stainless steel plate 12 on the plastic plate 10;

[0026] The lower surface of the plastic plate 10 is provided with a second composite adhesive layer 14 and a second stainless steel plate 15 in sequence. The shape of the second stainless steel plate 15 is the same as that of the plastic plate 10. on the plastic plate 10.

[0027] The outer surface of the second stainless steel plate 15 is coated with a second color coating 16 .

[0028] Both the thickness of the first stainless st...

Embodiment 2

[0039] The features of this embodiment are basically the same as those of Embodiment 1, except for the difference: the thickness of the first stainless steel plate 12 and the thickness of the second stainless steel plate 15 are both 0.1 mm; the extruding temperature of the extruder is 150°.

Embodiment 3

[0041] The features of this embodiment are basically the same as those of Embodiment 1, except that the thickness of the first stainless steel plate 12 and the thickness of the second stainless steel plate 15 are both 0.2 mm; the extruding temperature of the extruder is 160°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com