Stainless steel pipe thin-film automatic packaging machine

A technology of automatic packaging machine and stainless steel tube, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items, which can solve the problems of low packaging efficiency and achieve the effect of improving efficiency and good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

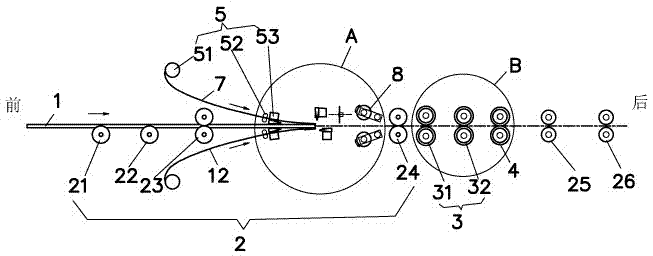

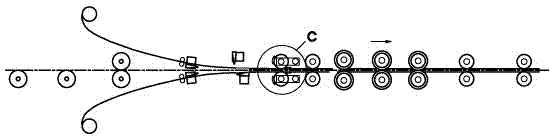

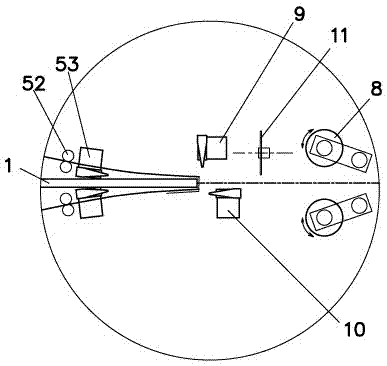

[0024] Such as Figure 1 to Figure 4 As shown, the stainless steel tube multi-track conveying guide roller 2 of the present invention comprises a plurality of same guide rollers as a group, and one group is provided with 8-20, and the present embodiment is provided with 10, and 10 can be packaged synchronously at a time, but It is not limited to this amount. The stainless steel tube multi-track conveying guide rollers are respectively arranged on the stainless steel pipe conveying path, and each stainless steel tube multi-rail conveying guide roller is provided with a set of guide grooves 211, the distance between the guide grooves is equal, and the notch edge sections of adjacent guide grooves The spacing of 212 is greater than 5 mm, generally between 5 mm and 50 mm, and the spacing is set for the convenience of hot pressing. A group of stainless steel pipe multi-track conveying guide rollers are horizontally arranged on the path of steel pipe conveying. When working, a stai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com