Gravity offset device for high-precision micrometer balls made of diamagnetic materials

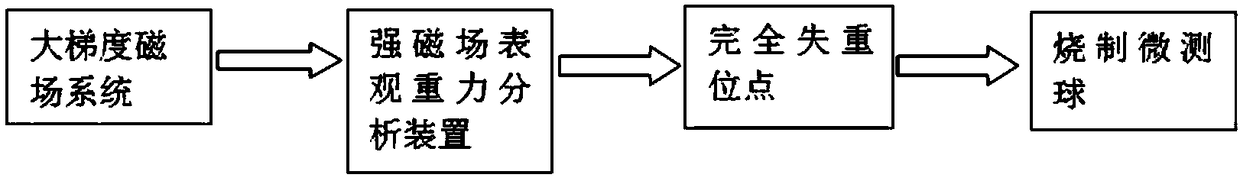

A diamagnetic, high-precision technology, applied in the direction of microstructure devices, microstructure technology, nanostructure manufacturing, etc., can solve the problems that the micrometer ball does not meet the coaxiality, cannot guarantee the coaxiality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

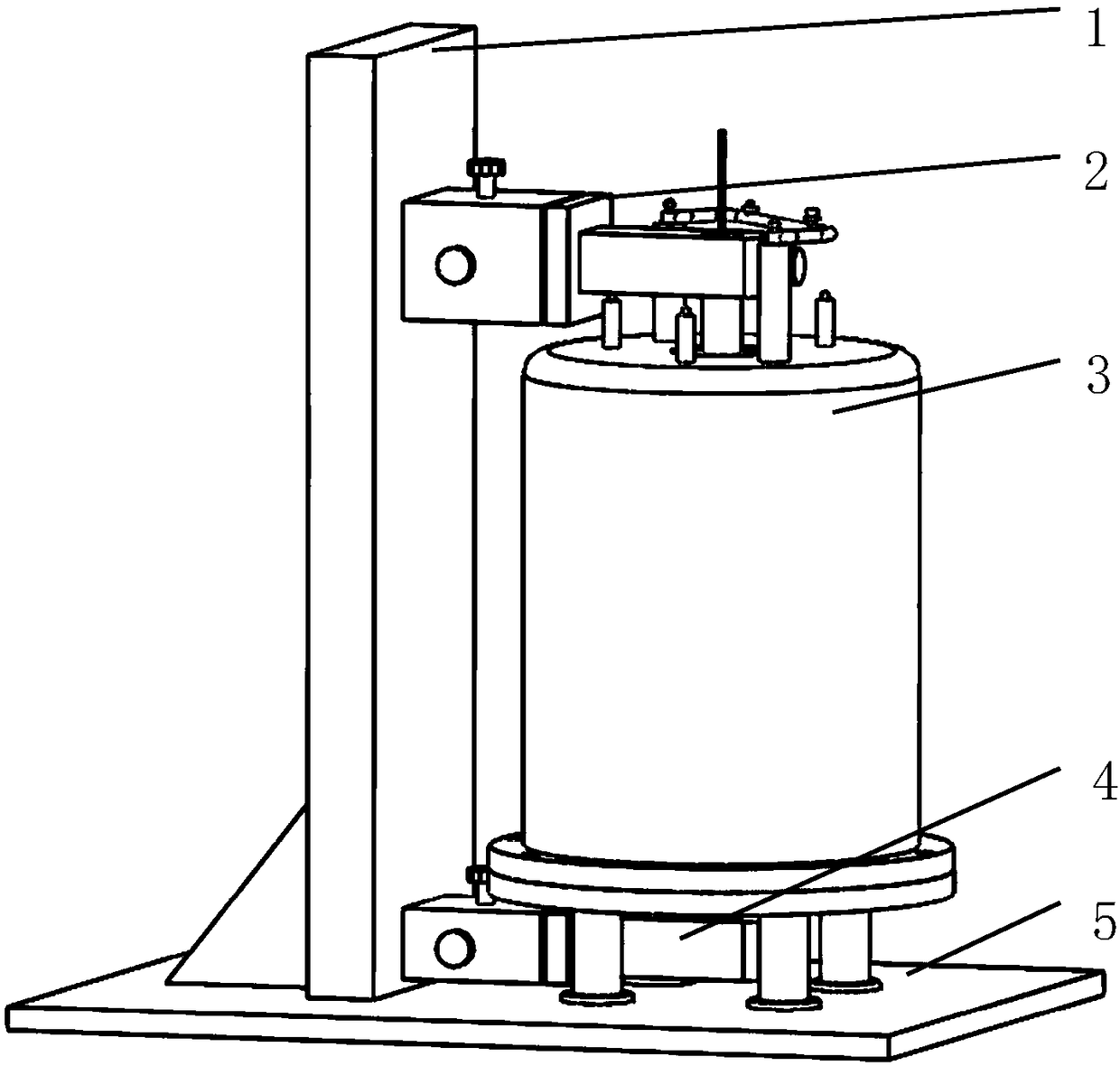

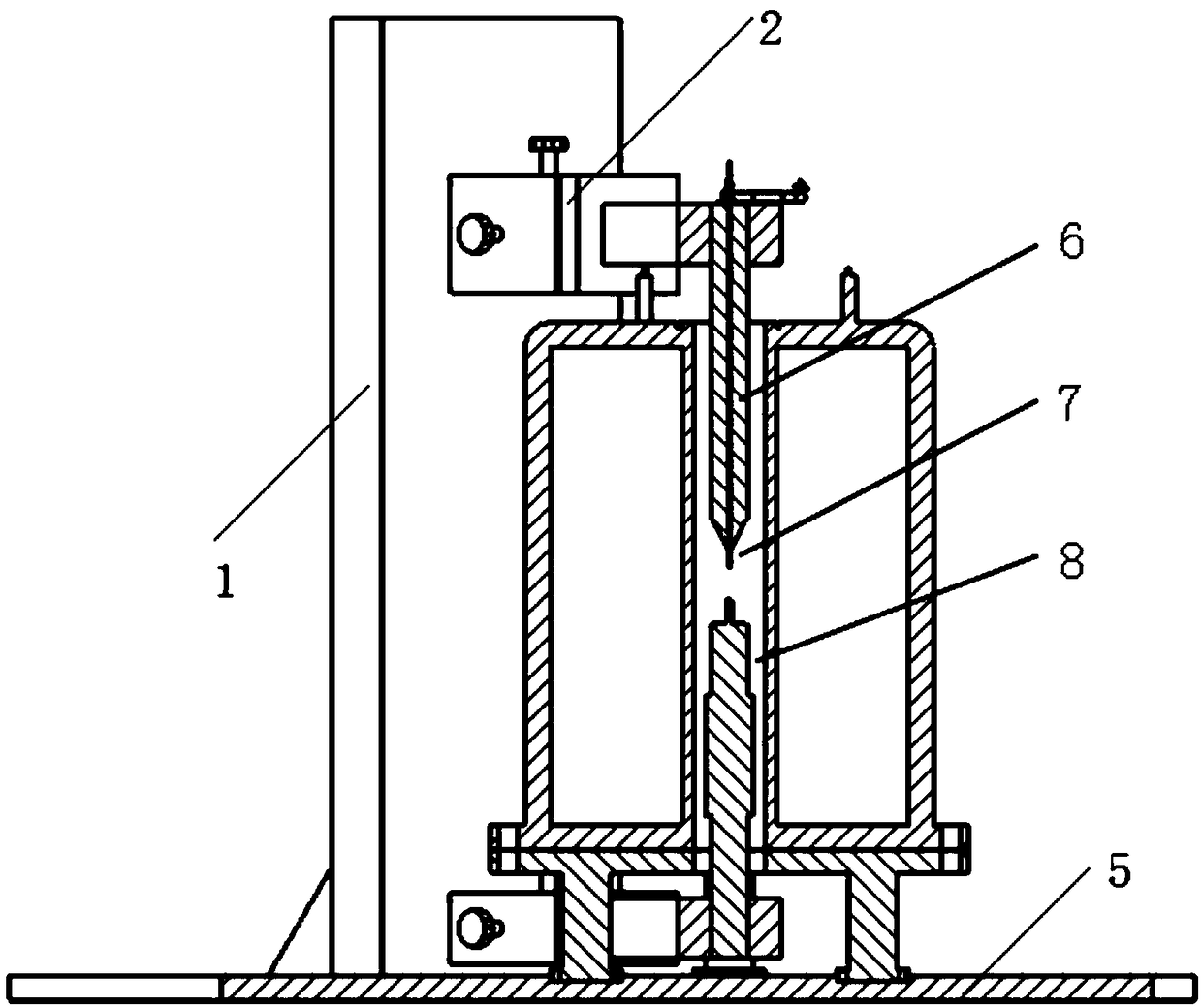

[0021] Referring to the accompanying drawings, the gravity offset device for preparing high-precision micrometer balls made of antimagnetic materials includes an optical platform 5, a large gradient strong magnetic field system, and a strong magnetic field apparent gravity analysis device. The three-dimensional displacement burning ball device is placed on the optical platform 5, and the three-dimensional displacement The ball burning device includes an upper three-dimensional displacement platform 2 and a lower three-dimensional displacement platform 4, and the upper three-dimensional displacement platform 2 and the lower three-dimensional displacement platform 4 are fixedly connected into one body through the detection bracket 1, and a pencil with a middle hole is fixed on the upper three-dimensional displacement platform 2 Cylinder 6, diamagnetic material silk thread 7 is inserted in the middle hole of pencil-shaped cylinder 6, electric spark plug 8 is fixed on the lower thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com