Motor, air supply device and household appliance

A technology of air supply device and rotor structure, which is applied in electromechanical devices, pump devices, components of pumping devices for elastic fluids, etc., which can solve the inflexibility of the mutual position of the stator and the rotor, which is not conducive to the lightweight design of products, and increases the number of products Size and other issues, to achieve the effect of reducing weight, improving overall stability, and reducing counterweight settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

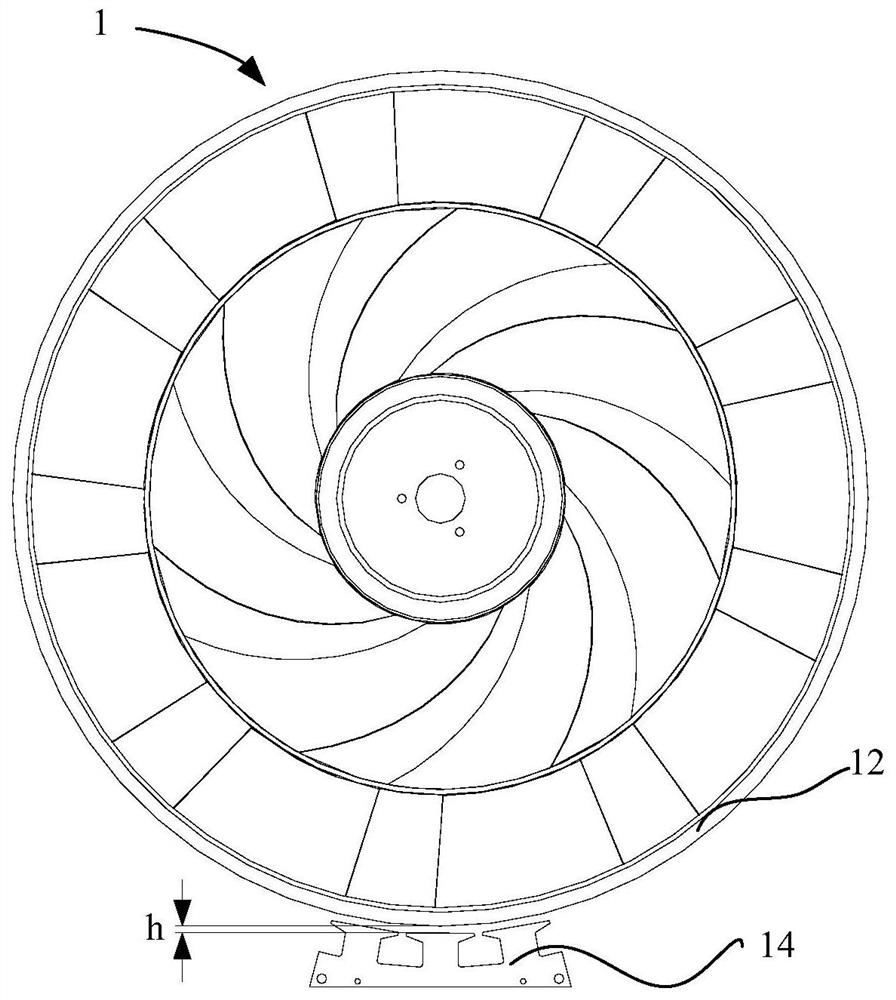

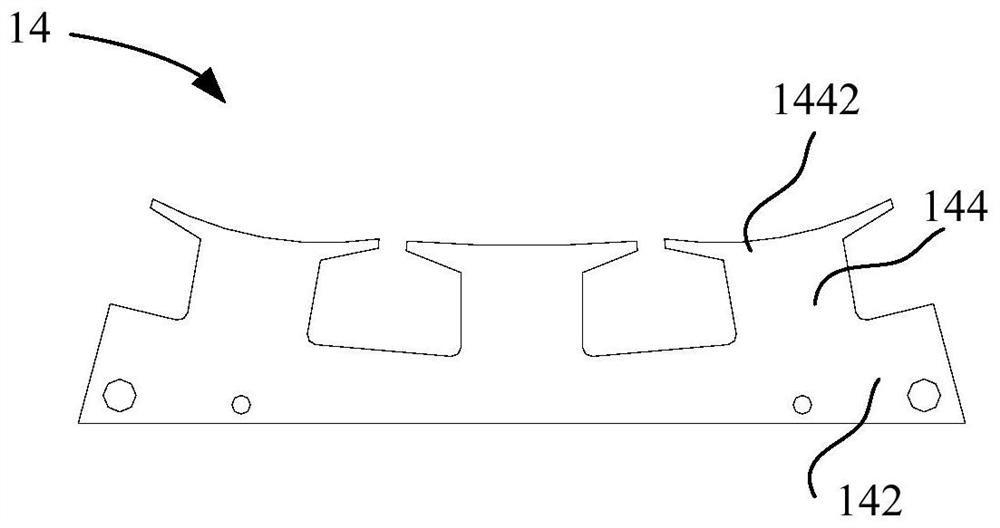

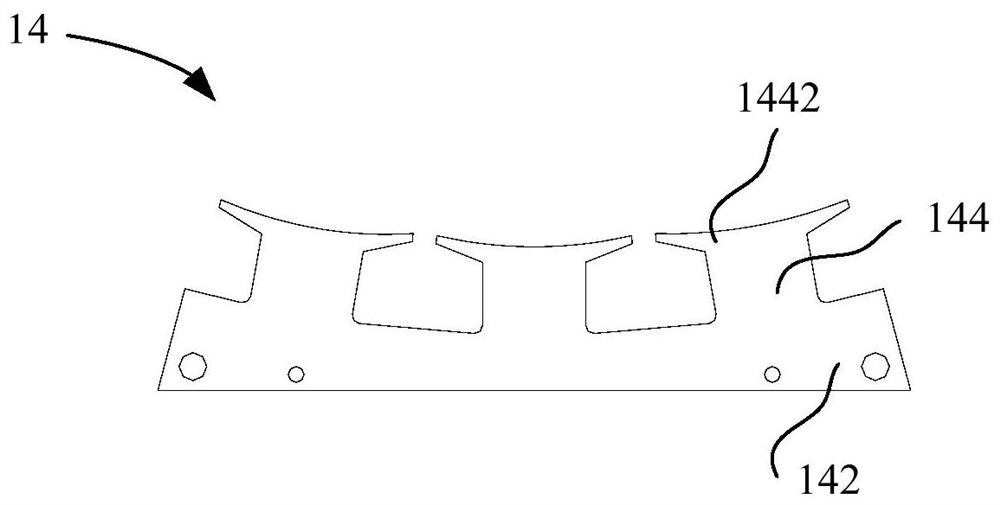

[0120] Such as Figure 1 to Figure 4As shown, one embodiment of the present application proposes a motor 1 , including a rotor structure 12 and a stator structure 14 that are detachably connected. Wherein, the rotor structure 12 is circular, the stator structure 14 is arranged on one side of the rotor structure 12 along the radial direction and there is a gap between the rotor structure 12, the stator structure 14 includes at least one stator arranged along the circumference of the rotor structure 12 The iron core 142 is used to form a driving force on the rotor structure 12 through the stator iron core 142 , and then drive the rotor structure 12 to rotate. The motor 1 is provided with a drive area, the drive area includes a stator core 142 and the part where the rotor structure 12 and the stator structure 14 are facing each other, so that the stator structure 14 in the drive area interacts with the rotor structure 12 to generate a drive rotor structure 12 The driving force o...

Embodiment 2

[0127] Another embodiment of the present application provides a motor 1, including a detachably connected rotor structure 12 and a stator structure 14, wherein the rotor structure 12 is in the shape of a ring, and the stator structure 14 is arranged on one side of the rotor structure 12 along the radial direction. The stator structure 14 includes at least one stator core 142 arranged along the circumference of the rotor structure 12 to form a driving force for the rotor structure 12 through the stator core 142, thereby driving the rotor structure 12 to rotate . Such as figure 1 As shown, the stator structure 14 includes a stator core 142 provided with three stator teeth 144, and windings are arranged on the stator teeth 144, and the polarities of the two adjacent stator windings are different, and the two adjacent stator windings Simultaneously energize, so that the stator structure 14 generates a magnetic field to drive the rotor structure 12 to rotate, specifically, first e...

Embodiment 3

[0135] Another embodiment of the present application provides a motor 1 , including a rotor structure 12 and a stator structure 14 , and the rotor structure 12 is detachably connected to the rotor structure 12 . Wherein, the rotor structure 12 is circular, the stator structure 14 is arranged on one side of the rotor structure 12 and there is a gap between the rotor structure 12, the stator structure 14 includes at least one stator core 142 arranged along the circumference of the rotor structure 12, A driving force is formed on the rotor structure 12 through the stator core 142 to drive the rotor structure 12 to rotate.

[0136] Such as Figure 4 As shown, the rotor structure 12 includes a plurality of magnetic pieces 122 , and the stator structure 14 is arranged corresponding to the magnetic pieces 122 . Wherein, a plurality of magnetic pieces 122 are arranged continuously along the circumferential direction.

[0137] Further, the magnetic member 122 is a magnetic sheet, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com