Sealed linear module and manufacturing method thereof

A linear module, closed technology, applied in the direction of linear motion bearings, bearings, shafts and bearings, etc., can solve the problems that the linear module cannot be completely sealed, and the high-precision operation of the linear module cannot be guaranteed. The effect of precise operation, convenient assembly, and improved assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

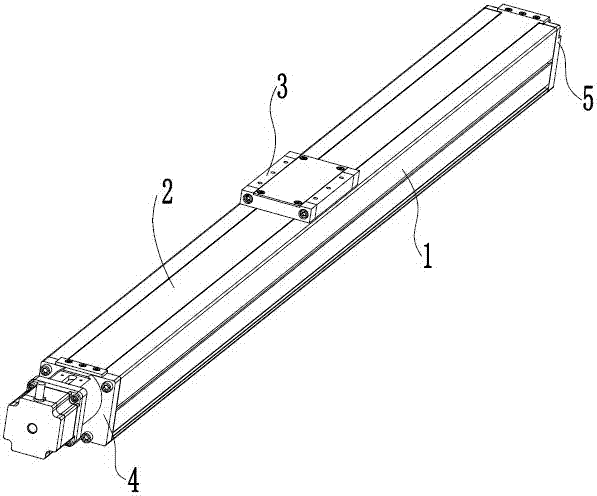

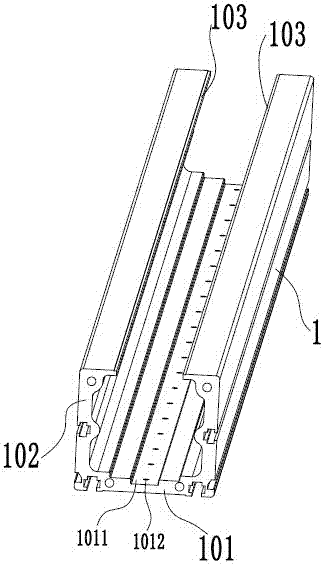

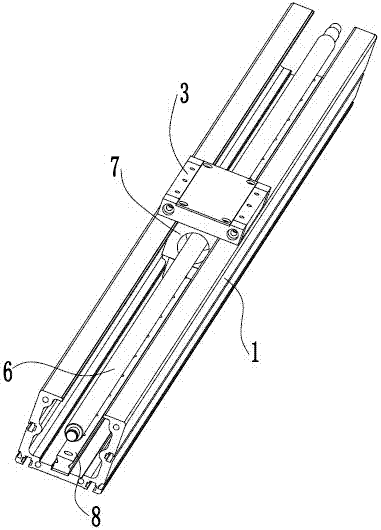

[0051] Such as Figure 1 to Figure 3 , Figure 10 As shown, the closed linear module of this embodiment includes a U-shaped module profile 1, and the module profile 1 includes a profile bottom plate 101 and profile side 102 walls provided on both sides of the profile bottom plate 101. A sealed tape assembly is provided above the wall 102, and end caps 5 are provided at both ends of the profile side wall 102 to form a closed space for the installation and movement of the sliding parts of the module; the tape assembly includes a plastic material tape 2. The sliding part of the module includes a slider assembly 7 and a slider connection box 3. The slider connection box 3 is provided with a threading structure for the tape 2 to pass through. The tape 2 and the threading The loosening section 202 is provided for structural cooperation, so that when the slider connection box 3 runs with the slider assembly 7, the sealing tape 2 and the profile side wall 102 remain closed. In this ...

Embodiment 2

[0055] According to the closed linear module described in embodiment 1, such as Figure 5 to Figure 9 As shown, the slider connection box 3 of this embodiment includes a connection box bottom plate 301 and belt threading side columns 303 arranged on opposite sides of the connection box bottom plate 301, and the two belt threading side columns 303 and the connection box bottom plate 301 There is a tape threading gap 10, and a tape inlet and a tape outlet are formed on the slider connection box 3 .

[0056] In this example, if Figure 6 As shown, the threading side column 303 is set to be detachable, which is convenient for the threading operation of the sealing tape and improves the assembly efficiency; and leaving a threading gap between the threading side column and the bottom plate of the connection box is convenient for the sealing tape and the bottom plate of the connection box. The assembly of the slider connection box is also convenient for observing and adjusting the s...

Embodiment 3

[0062] According to the closed linear module described in embodiment 1 or 2, such as image 3 and Figure 4 As shown, the upper top surface of the linear guide rail 8 in this embodiment is a sliding surface for sliding the slider, and slideways for sliding the slider are provided on both sides of the linear guide rail 8, and the slideway walls are concave curved surface structure. The sliding surface of the linear guide is set as a plane, which is beneficial to maintain the stability of the sliding of the slider, and the slideway for the sliding of the slider is set on the side of the linear guide, and the sliding structure is correspondingly set on the slider to make the slider and the linear guide It is a sliding surface in contact with three sides, which ensures the smoothness and accuracy of the slider sliding, thereby improving the precision of the entire linear module.

[0063] Further, the slider assembly 7 includes a slider 701 and a slider 702 connected thereto. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com