Novel ICL (industrial computed laminography) system and implementation method

A new type of imaging method technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of no focusing system structure complexity, cost, high-precision C-arm manufacturing complexity, low system flexibility, etc., to simplify scanning The effect of structure and movement mode, improving system flexibility, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0039] 1. Imaging model

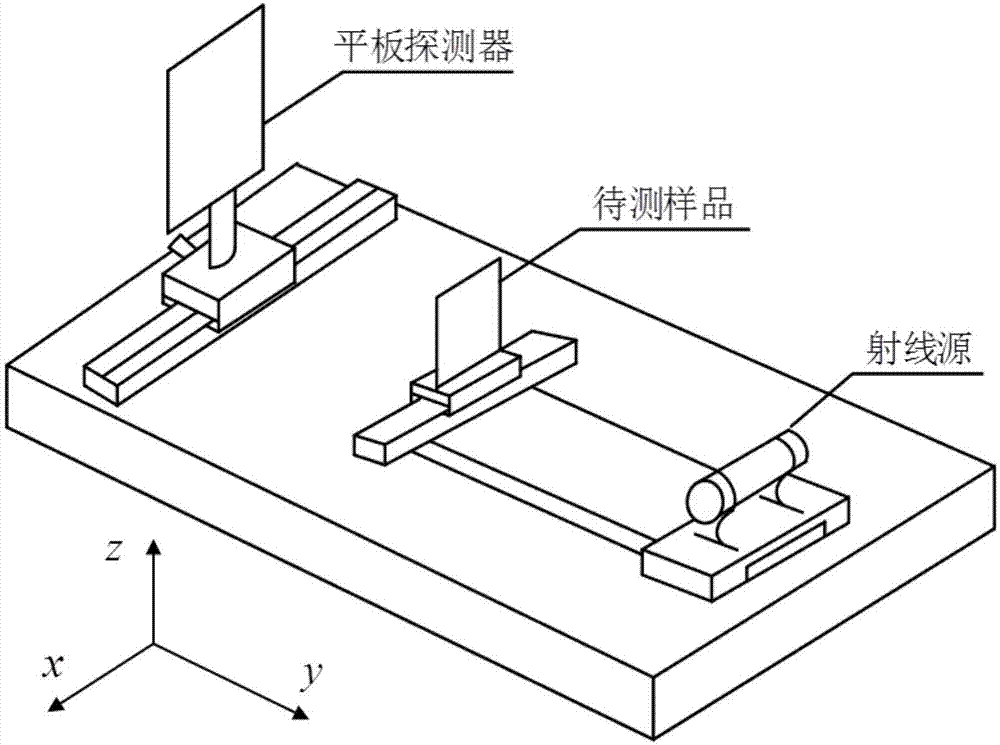

[0040] The data acquisition method is based on the synchronous parallel linear motion of the detector and the sample to be measured. Such as figure 1 As shown, the ray source is fixed on the platform, and the flat panel detector and the sample to be tested move in parallel and straight lines in the same direction. At the same time, the flat panel detector rotates synchronously during the scanning process, so that the detector is always in contact with the ray source during the data acquisition process of the system. The center beam is vertical.

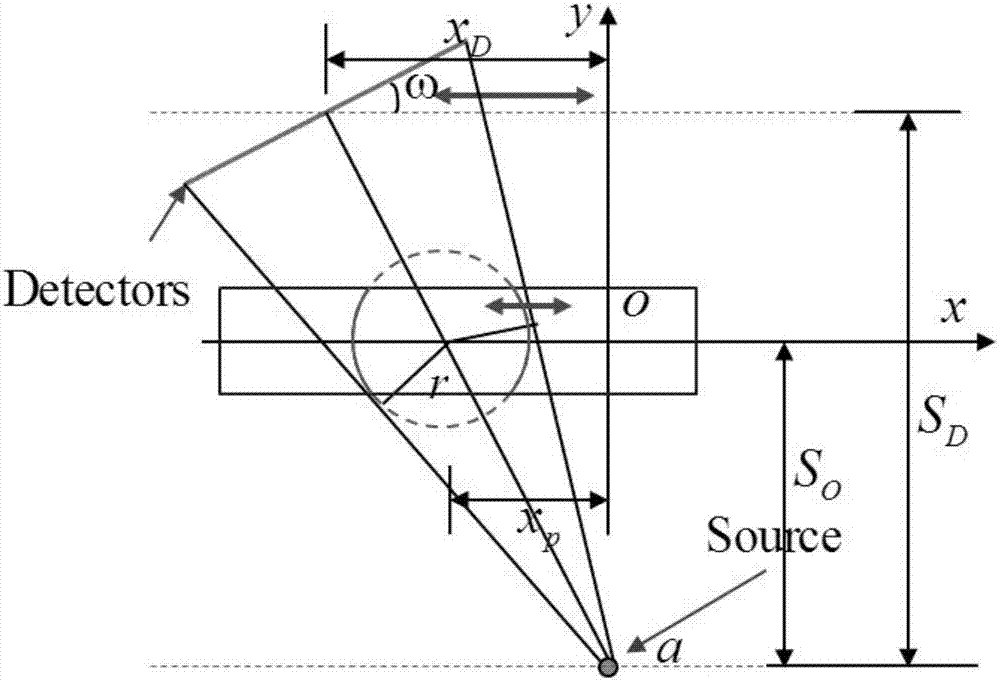

[0041] Such as figure 2 shown. The point at which the X-ray source is closest to the sample track is taken as the origin, and the moving direction of the sample is the positive direction of the x-axis to establish a rectangular coordinate system. The ray source is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com