Measurement device for volume deformation of foam concrete under condition of steam curing

A technology of foam concrete and volume deformation, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of continuous measurement of foam concrete deformation, inaccurate measurement, etc., to reduce errors, high measurement accuracy, and high stability and the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

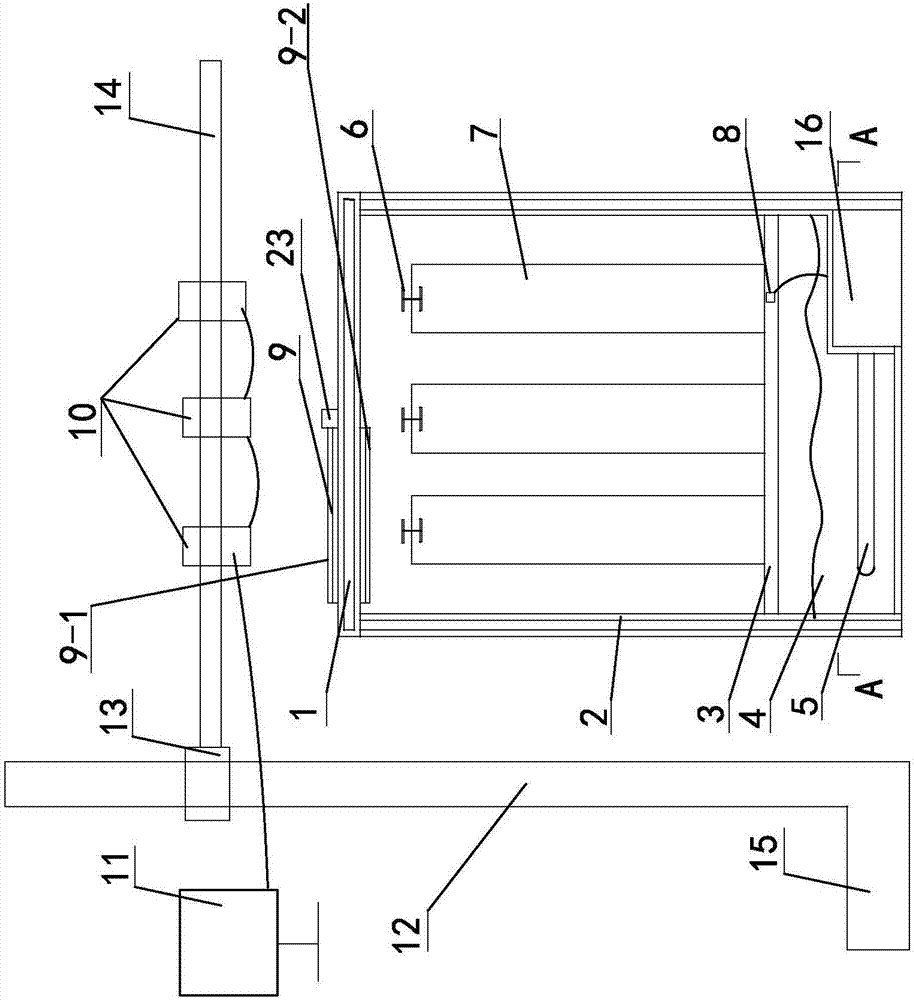

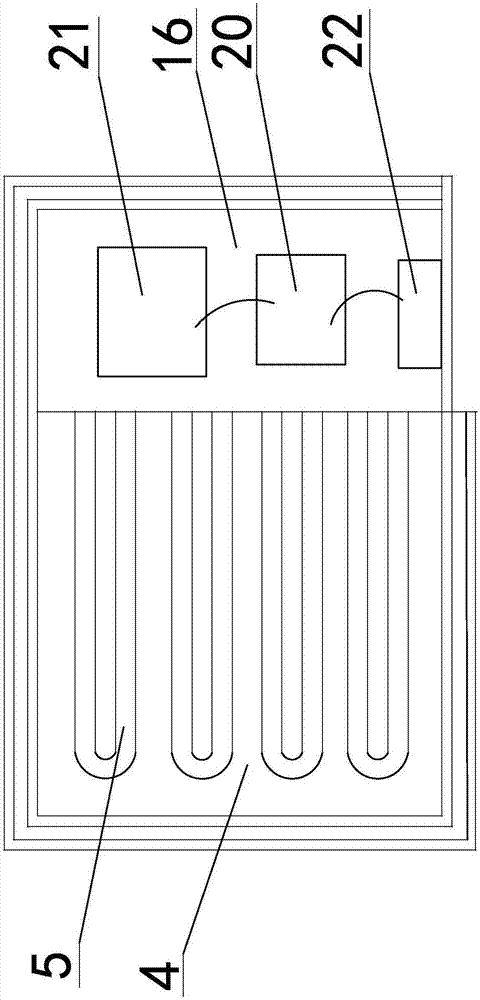

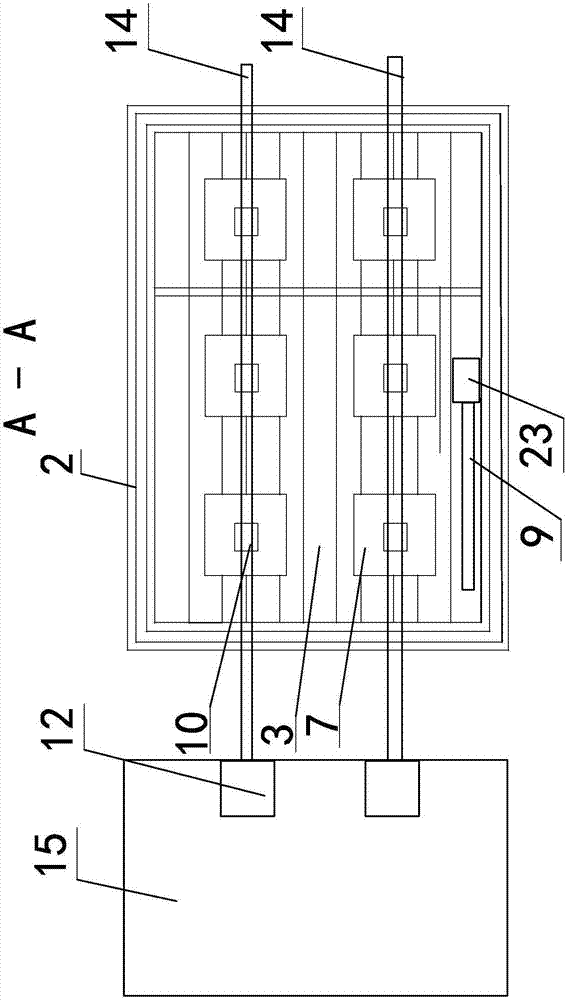

[0013] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment, the test device for the volume deformation of foamed concrete under steam curing conditions described in this embodiment, it includes a box cover 1, a box body 2, a heating water tank 4, a plurality of temperature sensors 8, an automatic wiper assembly 9, a computer 11. Connector 13, bracket base 15, temperature control box 16, two brackets 12, two beams 14, multiple spacers 3, multiple heating tubes 5, multiple reflection targets 6, and multiple test mold components 7 , a plurality of laser displacement sensors 10, the case cover 1 is a transparent heat preservation cover body, the case body 2 is a transparent heat preservation case body with an opening at the top, a temperature sensor 8 is installed on a plurality of spacers 3, and the bottom of the case body 2 is provided with a heating Water tank 4 and temperature control box 16, a plurality of heating pipes 5 are installed on the...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination Figure 1-Figure 2 Illustrate this embodiment, a kind of test device of foam concrete volume deformation under steam curing condition described in this embodiment, case cover 1 is the case cover that is made by vacuumizing in the middle of double-layer transparent glass, and the side wall of case body 2 is made of The side walls of the box body 2 made of double-layer transparent glass are vacuum-pumped in the middle. pass through, and the others are the same as in Embodiment 1.

specific Embodiment approach 3

[0015] Specific implementation mode three: combination figure 1 Describe this embodiment, a device for testing the volume deformation of foamed concrete under steam curing conditions described in this embodiment, the automatic wiper assembly 9 includes a first wiper part 9-1, a second wiper part 9-2 and a wiper motor 23, the first A bar magnet is installed on the first wiper part 9-1, and a bar magnet is installed on the second wiper part 9-2. One end of the first wiper part 9-1 is fixedly connected with the rotating shaft of the wiper motor 23, and the motor of the wiper motor 23 The seat is arranged on the upper end surface of the case cover 1, the first wiper member 9-1 rotates around the rotating shaft of the wiper motor 23, the second wiper member 9-2 is arranged on the lower end surface of the case cover 1, and the first wiper member 9-1 The bar magnet on the top and the bar magnet on the second wiper piece 9-2 attract each other. When the rotating shaft of the wiper mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com