Method and device for realizing spontaneous sequential flowage of multiple parts of liquid

A liquid and sequential technology, applied in the field of microfluidics, can solve problems such as occupying working time and affecting work efficiency, and achieve the effect of improving work efficiency and saving labor time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

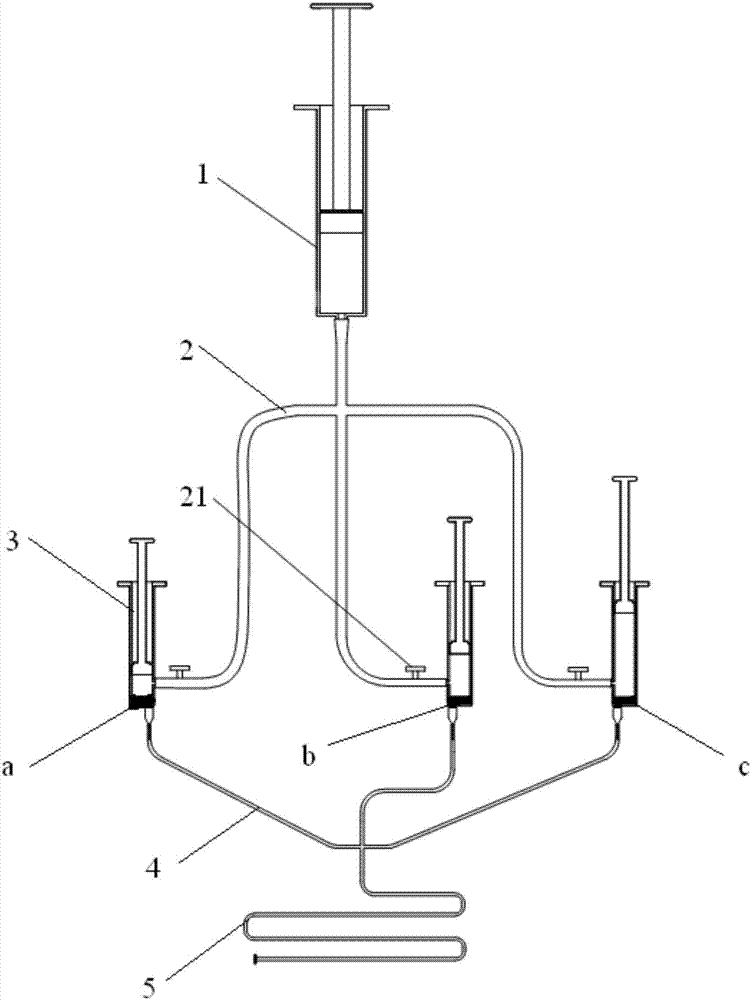

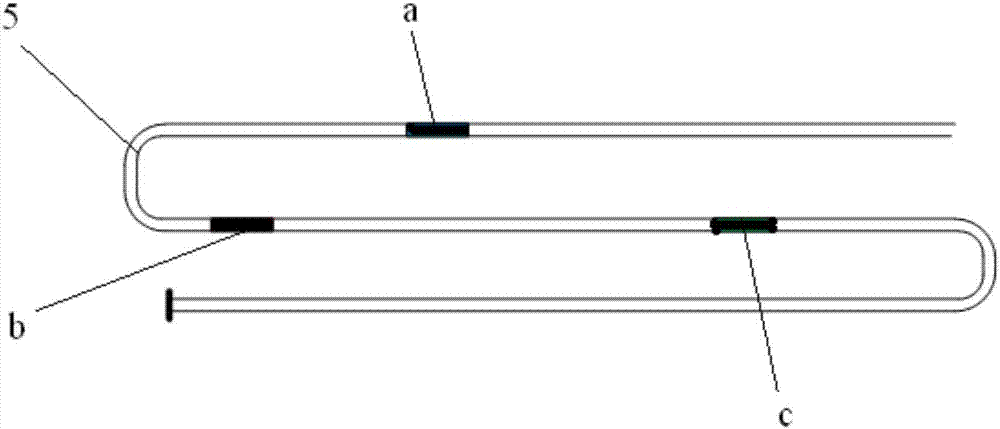

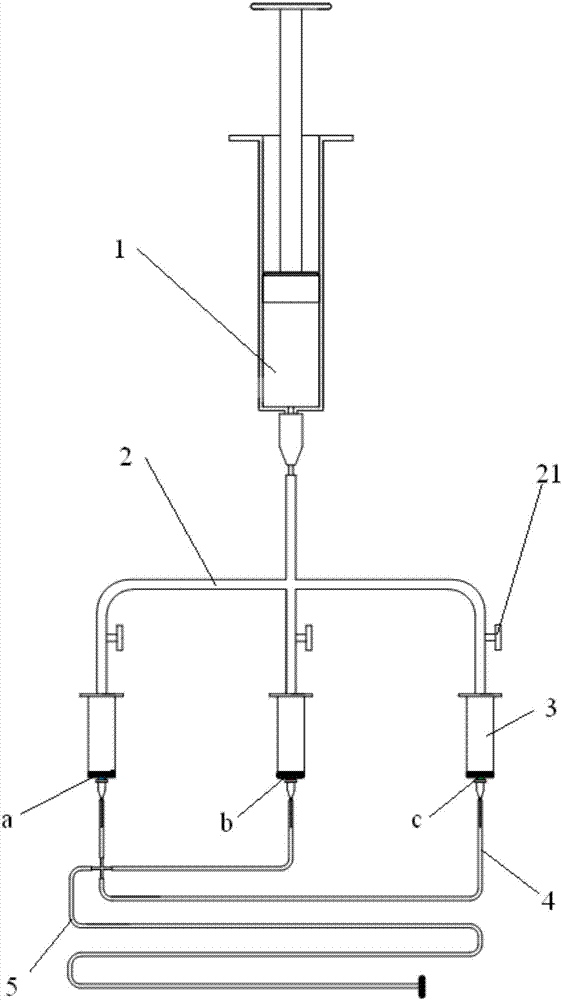

[0034] In Embodiment 1, the pressurizer 1 and the airtight container 3 are syringes, specifically, a 20ml syringe is used as the pressurizer 1, three 5ml syringes are used as the airtight container 3, and the three airtight containers 3 are connected to the air supply pipe 2 and the airtight container 3. The compressor 1 is connected, and the gas filling pipe 2 has an air inlet valve 21 near the airtight container 3 . Fix the three airtight containers 3 to the positions of 1ml, 3ml and 5ml respectively, and inject 100 microliters of blue ink a, red ink b and green ink c into the three airtight containers 3 respectively. The end of airtight container 3 links to each other with the connecting pipe 4 that flow path volume is all equal, and three connecting pipes 4 are connected with micropipe 5 by four-way pipe, and the end of micropipe 5 is connected with exhaust valve (not marked among the figure).

[0035] After completing the assembly of the device, close the exhaust valve at...

Embodiment 2

[0037] In the second embodiment, the pressurizer 1 and the airtight container 3 are syringes, specifically, a 20ml syringe is used as the pressurizer 1, and three 5ml syringes are used as the airtight container 3, and the three airtight containers 3 are connected to the air supply pipe 2 and the airtight container 3. The compressor 1 is connected, and the gas filling pipe 2 has an air inlet valve 21 near the airtight container 3 . Fix the three airtight containers 3 to the positions of 2ml, and inject 100 microliters of blue ink a, red ink b and green ink c into the three airtight containers 3 respectively. The end of the airtight container 3 is connected to the connecting pipe 4 with different flow channel volumes, wherein the blue ink a corresponds to the connecting pipe 4 with a length of 10 cm, the red ink b corresponds to the connecting pipe 4 with a length of 20 cm, and the green ink c corresponds to the connecting pipe 4. The length of pipe 4 is 40cm, and three connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com