Dust-proof lens cover used for sighting telescope

A scope and dust-proof cover technology, which is applied in the field of scope dust prevention, can solve the problems that the protective cover is easy to lose and cannot guarantee the dustproof performance, and achieves the effect of simple structure, no blocking of sight, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

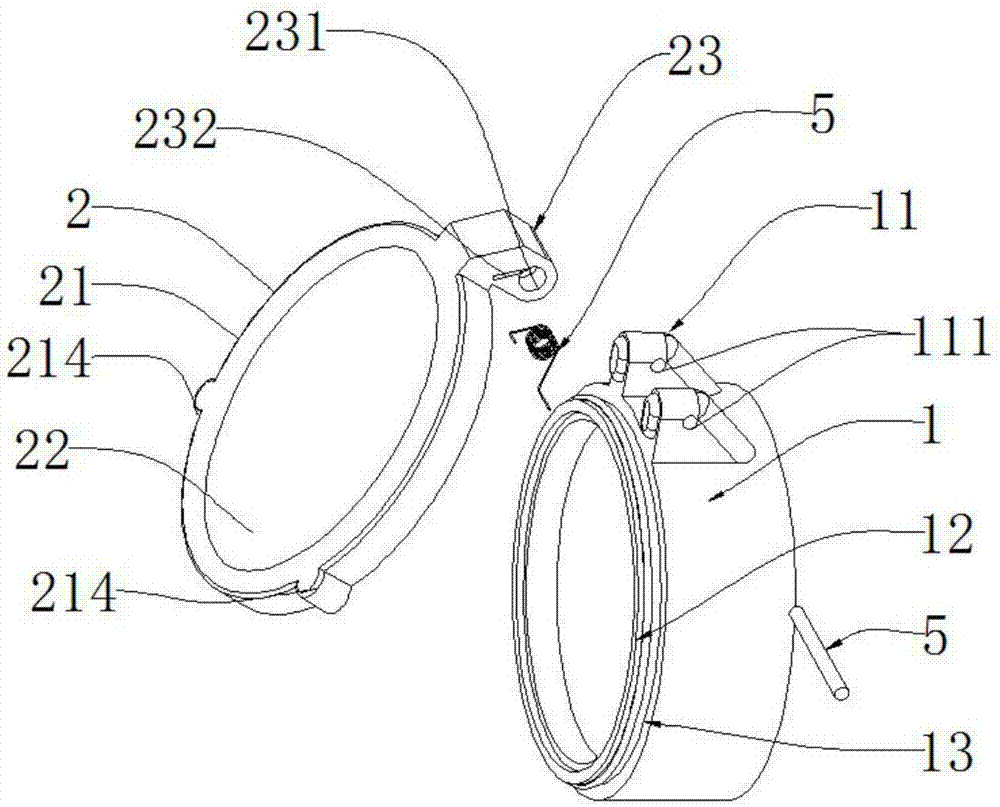

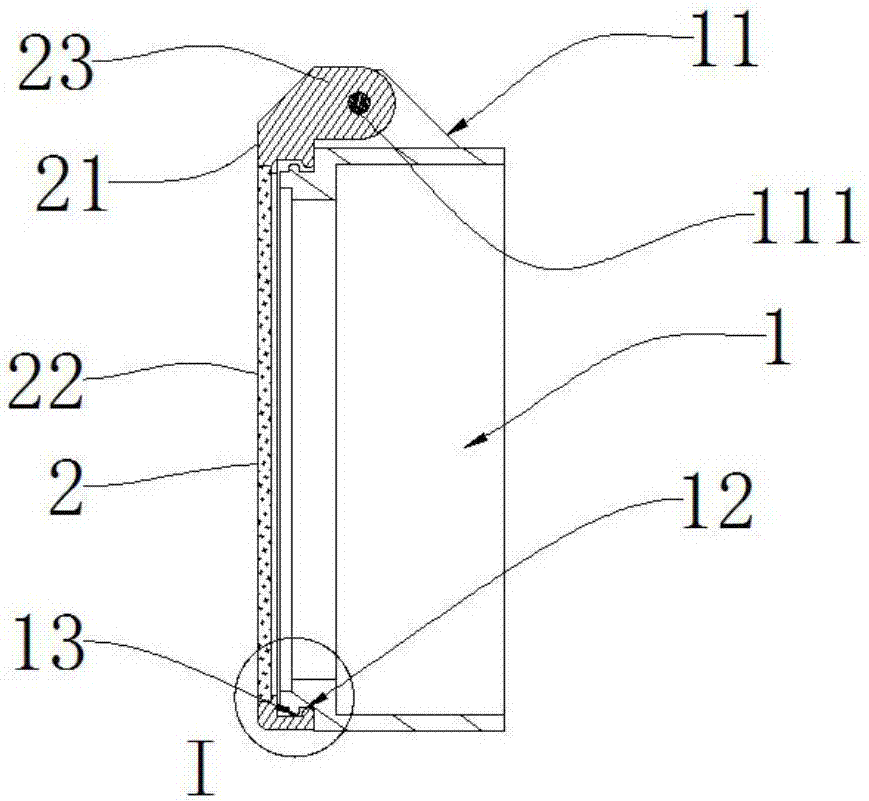

[0030] See Figure 1-6 , a dust-proof lens cover for a scope, which includes: a dust-proof cover installation sleeve 1, a dust-proof cover 2, a torsion spring 4, and a pin shaft 5;

[0031] The installation sleeve 1 is cylindrical and matches the eyepiece barrel or objective lens barrel of the sight;

[0032] The mounting sleeve 1 is provided with a hinge seat 11;

[0033] The hinge seat 11 is provided with a first hinge hole 111;

[0034] The end of the installation sleeve 1 is also provided with a locking outer flange 12;

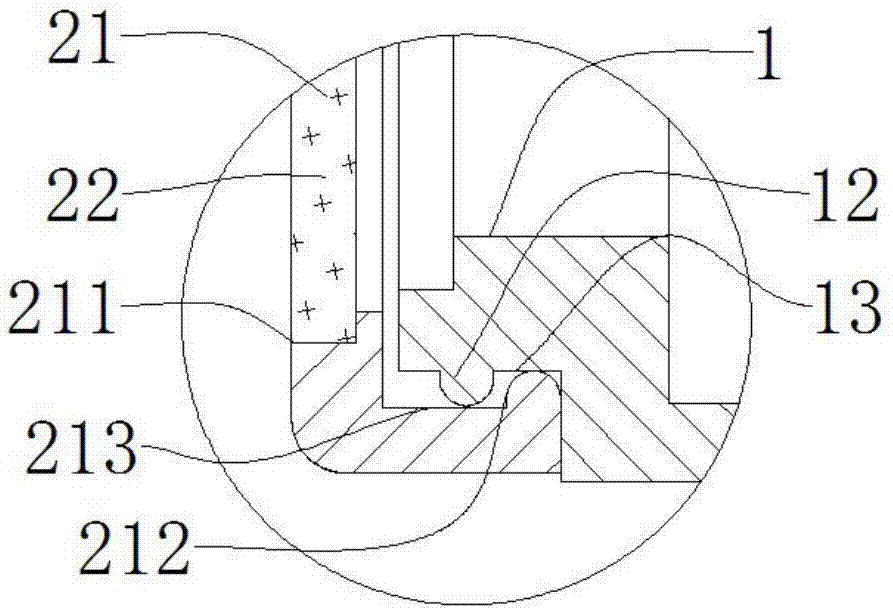

[0035] The inside of the locking outer flange 12 is provided with a locking inner flange receiving groove 13;

[0036] The dust cover 2 is disc-shaped;

[0037] The dust cover 2 includes a fixed ring 21, a transparent lens 22, and a hinged seat 23 for the dust cover;

[0038] The fixed ring 21 is annular, and the fixed ring 21 is provided with a transparent lens mounting groove 211 and a locking inner flange 212 inside;

[0039] The transparent lens...

Embodiment 2

[0056] See Figure 7-10 , a dust-proof lens cover for a scope, which includes: a dust-proof cover installation sleeve 1, a dust-proof cover 2, a torsion spring 4, and a pin shaft 5;

[0057] The installation sleeve 1 is cylindrical and matches the eyepiece barrel or objective lens barrel of the sight;

[0058] The installation sleeve 1 is provided with a vertical shaft 14; the vertical shaft 14 is perpendicular to the axis of the installation sleeve 1;

[0059] The mounting sleeve 1 is provided with a hinge seat 11;

[0060] The hinged seat 11 is installed on the vertical shaft 14, and the hinged seat 11 can rotate around the vertical shaft 14;

[0061] The hinge seat 11 is provided with a first hinge hole 111;

[0062] The hinge seat 11 is provided with a limit block 112, and the limit block 112 is located on the rear side of the first hinge hole 111, and is used to limit the position and angle of the dust cover 2 after it has bounced off;

[0063] The end of the installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com