Intelligent proofreading method and system for digital design of power plant

A power plant, intelligent technology, applied in the direction of electrical digital data processing, computer-aided design, calculation, etc., can solve the problems of checking omissions of reviewers, delay of construction period, large amount of reference data, etc., so as to improve the efficiency of checking, Eliminate the effect of omission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

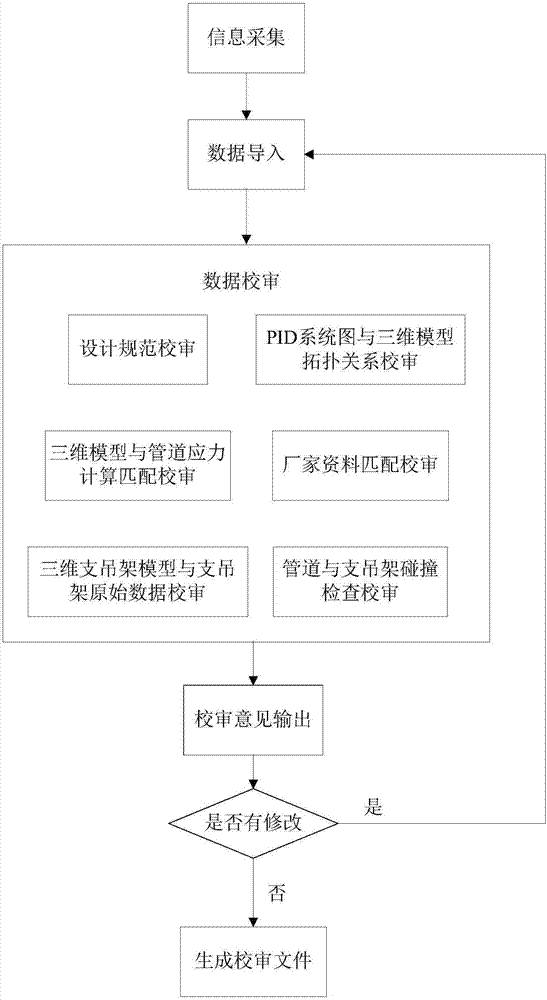

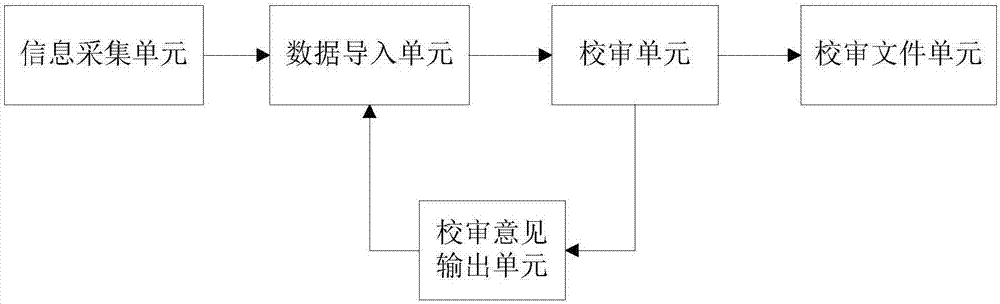

[0032] Such as figure 1 The system for digital design intelligent review of the power plant shown in the present invention includes sequentially connected:

[0033] Information acquisition unit: scans at least two-dimensional PID system diagrams and two-dimensional engineering drawings including manufacturer information into electronic data, and performs identification processing to generate graphic mapping diagrams and data text files;

[0034] Data import unit: extract the 3D model information of the checked pipelines and supports and hangers through 3D software, and classify and summarize the extracted information and the data generated by the information acquisition unit;

[0035] Proofreading unit: compare the data obtained by the information collection unit and the data import unit, and modify the difference data;

[0036] Review file unit: generate review files and send the review files to relevant personnel;

[0037] The review unit also feeds back into the data imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com