OLED display substrate and manufacturing method thereof, and display device

A technology for display substrates and manufacturing methods, applied in static indicators, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of large protective film area, diffusion, unfavorable display device narrow frame and no frame, etc., to achieve Narrow border and no border, the effect of reducing the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

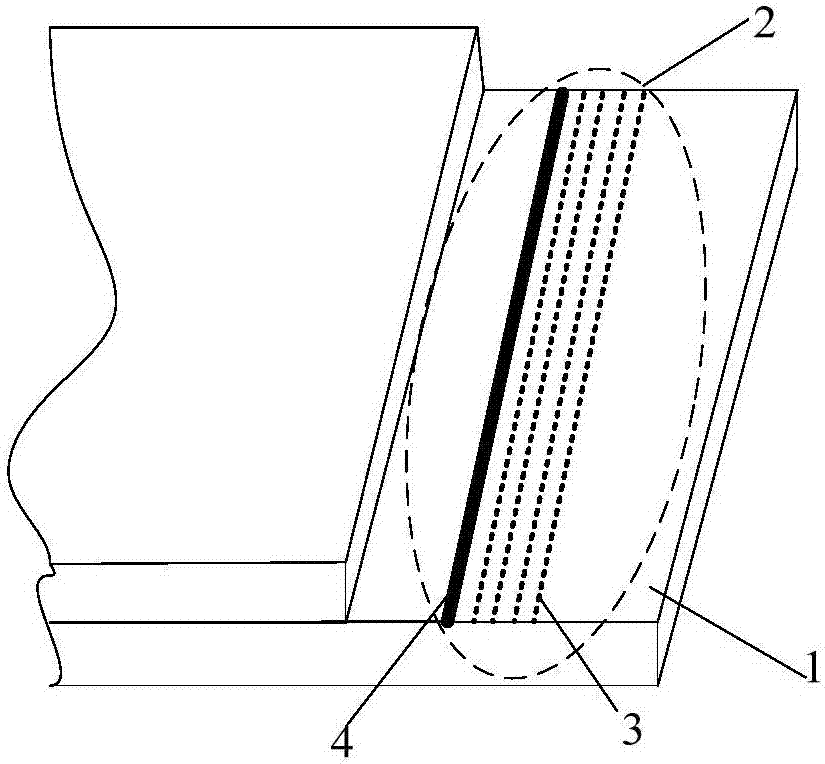

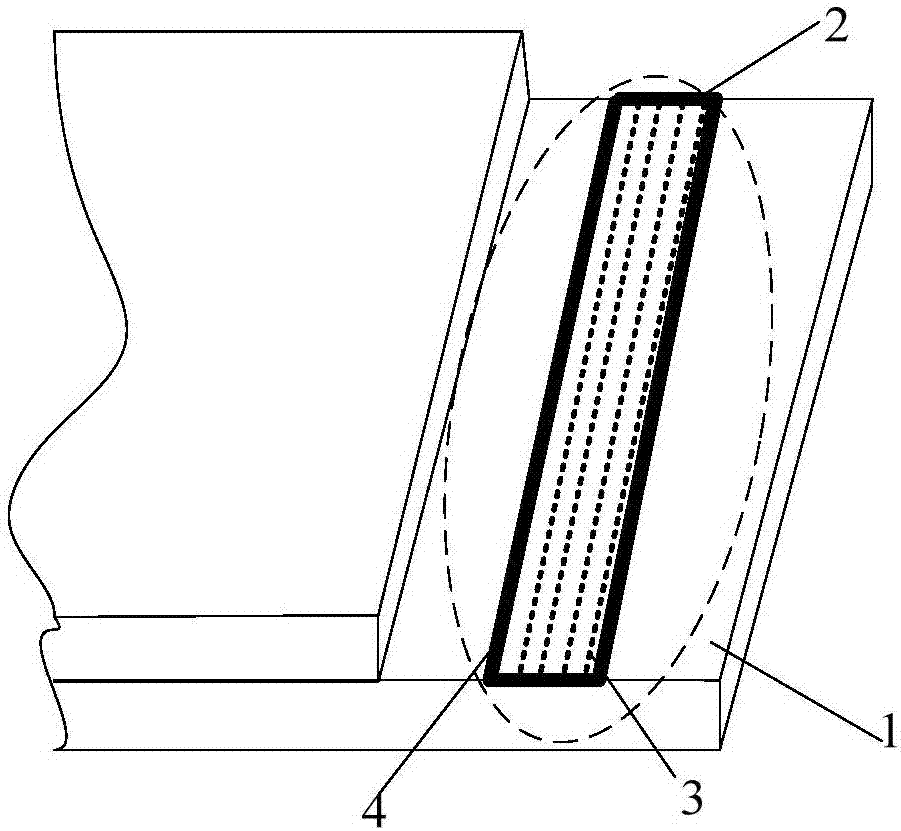

[0041] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0042] The embodiments of the present invention aim at the problem that in the prior art, in order to prevent the glue line from spreading to the display area, it is necessary to reserve a relatively large space at the edge of the display substrate to form a protective film, which is not conducive to the realization of a narrow frame and no frame of the display device, and provides An OLED display substrate, a manufacturing method thereof, and a display device can realize a narrow frame or even no frame of the display device.

[0043] An embodiment of the present invention provides a method for manufacturing an OLED display substrate, the OLED display substrate includes a display area and a wiring area, and the manufacturing method incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com