Backpack electric spray and foam jet all-in-one machine

An all-in-one, knapsack technology, which is used in devices, applications, animal husbandry, etc. to capture or kill insects, can solve the problems of uneven foam diameter, unstable air pressure, poor spraying effect, etc. Good, high foam production efficiency, controllable effect of foam diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

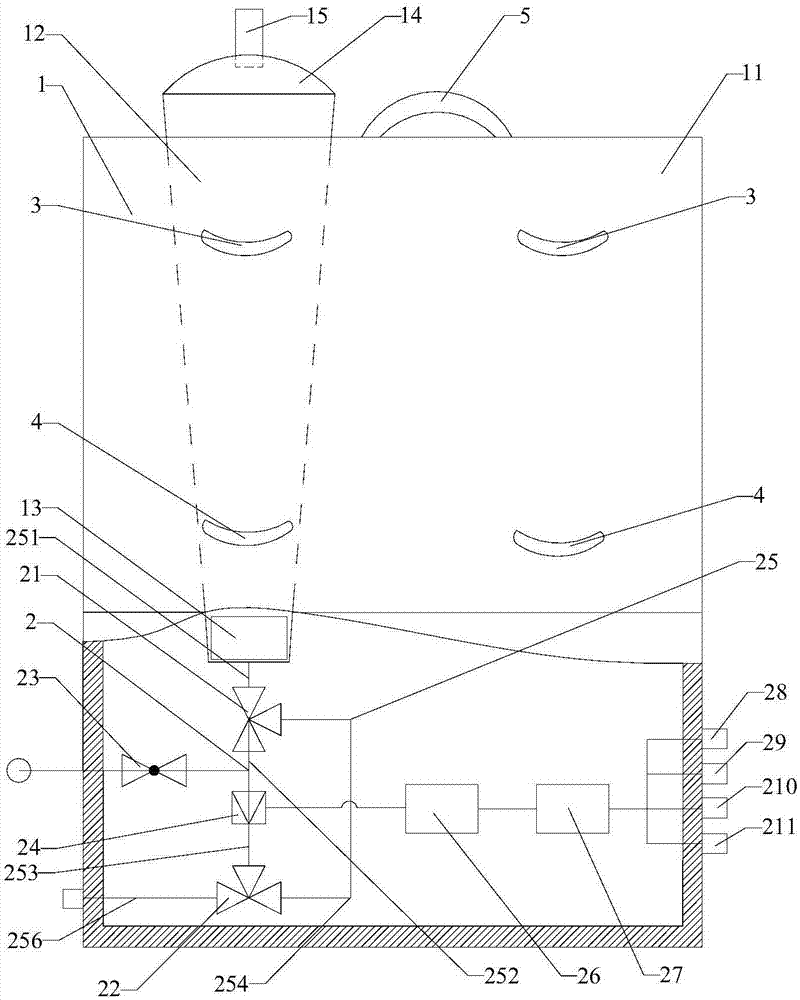

[0049] A knapsack-type electric spray and foam injection integrated machine, including an integrated machine body, the integrated machine body includes a liquid storage device 1 and a pipeline control device 2; the liquid storage device 1 is located on the upper part of the pipeline control device 2; The liquid device 1 includes a liquid storage cylinder 11, a filter bucket 12 and a foaming box 13 arranged in the liquid storage cylinder 11, the shape of the filter bucket 12 is an inverted circular frustum, and the upper end of the filter bucket 12 is higher than the liquid storage cylinder. 11, the bottom of the liquid storage cylinder 11 is provided with a groove matching the bottom of the filter bucket 12, and the bottom of the filter bucket 12 communicates with the liquid storage cylinder 11 through the groove; the bottom of the filter bucket 12 is provided with Foaming box 13; the pipeline control device 2 includes a cavity disposed at the bottom of the liquid storage cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com