Shoe upper head position control structure in upper grabbing process, and upper grabbing method

A technology of head position and control structure, which is applied in the direction of shoe last, footwear, application, etc., can solve the problems of inconspicuous improvement in production efficiency, and achieve the effect of tight fit, improved operation, and guaranteed product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

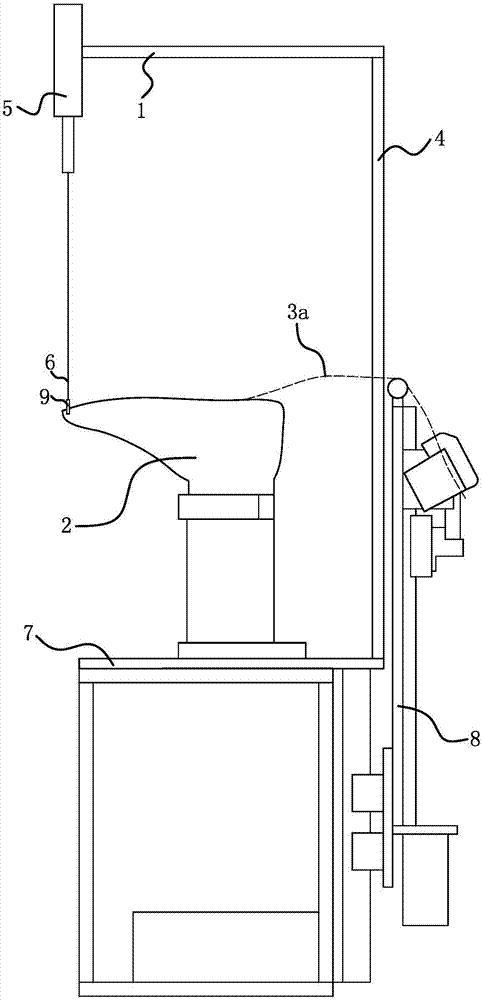

[0025] Such as figure 1 As shown, the head position control structure of the shoe upper 3 in the upper gripping process includes a bracket 1 and a positioning member 9 .

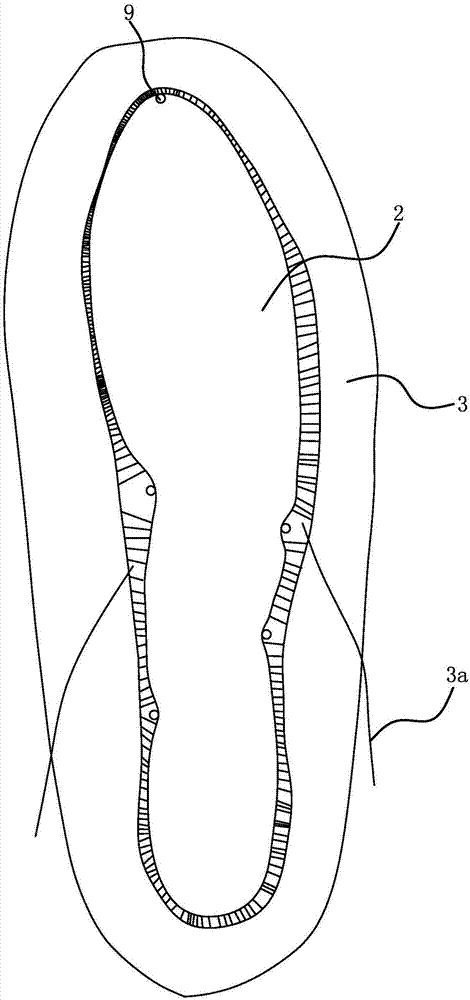

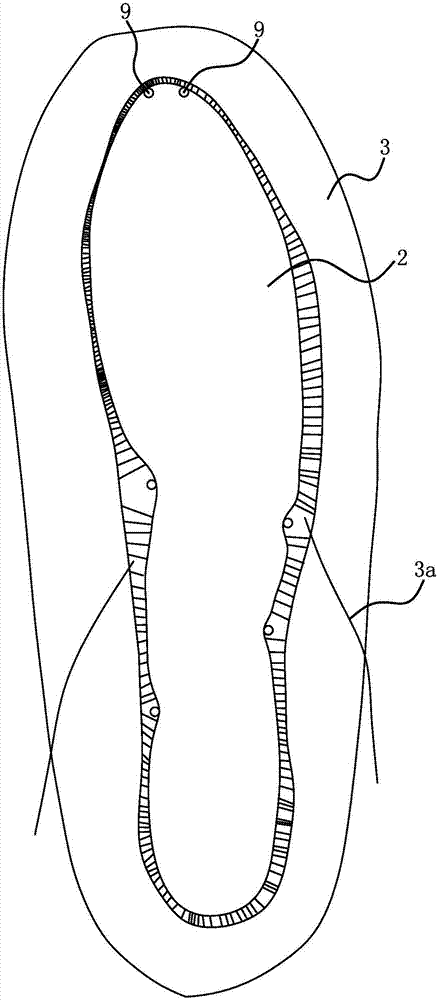

[0026] The positioning member 9 is a positioning rod, and the number of the positioning rods is 1-3. Instructions attached figure 2 The number of positioning rods given is one, and the instructions are attached image 3 The number of positioning rods is given as two.

[0027] Positioning holes are arranged on the shoe last 2, and the number of positioning holes is the same as that of the positioning rods. The surface corresponding to the bottom opening of the shoe upper 3 in the shoe last 2 is the bottom surface; when the upper is grasped, the bottom surface of the shoe last 2 faces upward. The positioning holes are located on the bottom surface of the shoe last 2 head.

[0028] When the positioning piece 9 is inserted in the positioning hole and the shoe last 2 is covered with the upper 3, the positio...

Embodiment 2

[0033] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be redundantly described, and only the differences will be described, and the differences are as follows: Figure 4 As shown, the positioning member 9 is an arc-shaped metal sheet, and the number of the metal sheet is one. The positioning hole is strip-shaped and arc-shaped, and the shape of the positioning hole matches the shape of the metal sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com